Photo by emarts emarts on Unsplash

1. Introduction

A flexible and popular technique for imprinting graphics on a variety of materials is screen printing, often known as silk screening. Screen printing delivers a level of depth and tenacity that distinguishes it from other printing techniques, whether it is producing vivid t-shirts, detailed posters, or robust advertising.

Although, screen printing is widely used—typically in the field of graphics—understanding the physics behind it has not been entirely satisfying. However, it has experienced growth in applications including the production of multilayer solar cells as well as manufacturing methods like large region electronics and organic electronics, both of which have the ability to be printed over huge areas on reasonably priced substrates.

But, what is the basic procedure to follow in screen printing? What are the main types of it? How is screen printing done? What are the methods to follow? We will discover each step in full detail here. So let’s dive deep into it.

2. The screen printing process

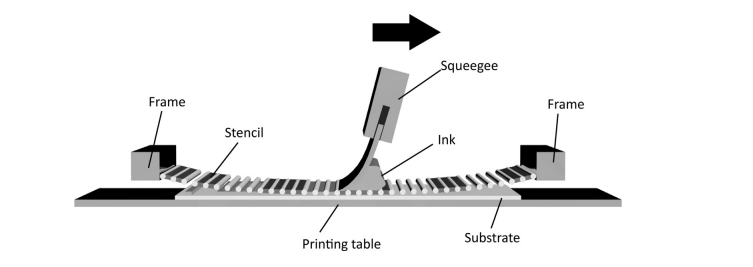

Screen printing is the technique that uses ink, a mesh screen, and a squeegee to transfer a stenciled design onto a flat surface. While the most common surfaces for screen printing are paper and cloth, it is also feasible to print on other materials like metal, plastic, glass, and wood.

A stencil procedure called screen printing uses both closed nonimage and open image sections to print. A strong squeegee is used in screen printing to drive ink through a screen.

Screen printing can be done in a variety of ways, however, they all use the same fundamental technique. The printing process we'll discuss below utilizes a particular light-reactive emulsion to build a unique stencil; it's often the most widely used commercial printing method because it may be used to create complicated stencils.

Here are the steps involved in screen printing.

1. The Design is Created

Starting with a sheet of clear acetate, the printer prints the image they want to show on the finished product. The stencil will be made using this.

Then based on the complexity of the pattern and the fabric's texture being printed out the printer will select a mesh screen to be used.

2. Setting up the Screen

The printer will then select a mesh screen based on the interaction of the design and the fabric’s texture being coated. A layer of light-reactive emulsion is then applied to the mesh screen, and when grown under strong light, the emulsion will solidify.

3. The Emulsion is Exposed

The emulsion-coated screen is then placed on top of the acetate sheet with the design, and everything is subjected to a very strong light. The sections of the screen that are surrounded by the pattern remain in liquid form because the light hardens the emulsion.

Each layer of ink must be applied using a separate screen if the end design will contain multiple layers of color. To produce multicolored items, the printer must utilize his creativity to design each stencil and precisely align them to provide a smooth final design.

4. The emulsion is extracted, producing the stencil

The parts of the screen not covered by the design will have hardened after being exposed to light for a predetermined amount of time. The remainder of the emulsion is then cautiously washed away. As a result, the design is clearly imprinted on the screen for the ink to pass in.

After the screen dries, the printer will make any required alterations or touch-ups to ensure that the imprint closely matches the initial layout. The stencil can now be applied.

5. The item is ready for printing.

After that, the printing press is equipped with a screen. The surface being printed is the flat surface of the printing board, which is positioned beneath the screen.

The majority of contemporary commercial printers use an automatic rotary printer because it enables multiple screens to work simultaneously. There are numerous various presses, including manual and automatic types. This kind of printer can also be utilized for multicolored prints to swiftly apply the various color layers.

6. The item is inked and pressed through the screen.

The printing board receives the screen as it is lowered. Using a squeegee, ink is applied to the screen's top end and pulled down the entire length of the screen. By doing this, the ink is forced through the stencil's open spaces and onto the product below, imprinting the design.

When printing multiple articles, the screen gets raised and a fresh item of clothing is set on the printing surface. Repeating the procedure continues.

The emulsion is cleaned from the mesh using a specialized cleaning fluid so it may be used again to make fresh stencils after all the things have been printed and the stencil has fulfilled its intended function.

7. The item is dried, examined, and polished.

The imprinted item is then dried, "curing" the ink and giving it a smooth, color-fast texture. Before being given to its new owner, the finished product will be properly checked and cleaned to eliminate any leftovers.

3. What are the Types of Screen Printing

The following kinds of screen printing inks can be divided based on how they dry: evaporative (water-based and solvent-based), oxidizing, catalytic, and UV inks.

We will discuss each category step by step.

UV screen Printing:

Utilizing specially formulated UV inks that are cured by ultraviolet light, UV screen printing utilizes this technique. Printing on a greater variety of materials, such as plastic, glass, and metal, is possible using this technique.

Catalytic Screen Printing

The process of applying catalytic ingredients to a substrate during the screen printing process is known as catalytic screen printing. These substances can start or speed up chemical reactions, frequently for specialized industrial or technological uses. Electronics, energy generation, environmental cleanup, and other industries can all benefit from this method. These are some uses and illustrations of catalytic screen printing: catalytic converters, water treatment, electrode fuel cells, and photovoltaic cells.

Oxidizing Screen Printing:

In order to provide a distinctive visual effect, oxidizing screen printing uses specialized inks or chemicals that interact with the fabric or substrate. This technique is frequently employed in textile and fabric printing to create a vintage or distressed look.

Evaporative Screen Printing:

The printing industry uses the specialized process known as evaporative screen printing largely to decorate fabrics. This technique makes use of a unique kind of ink that has volatile solvents. This is how it usually goes:

Formulation of ink:

Specially developed evaporative inks contain solvents that swiftly evaporate when subjected to air or heat.

Printing Method:

The screen with the intended layout or pattern is dropped onto the fabric, which has been spread out on the printing bed. The screen is then covered with the evaporative ink.

Squeegee Movement:

The ink is forced onto the fabric using a squeegee via the screen's open spaces.

Evaporation:

The solvents start to evaporate when the ink is put on. Due to the solvents' instability, this occurs quickly.

Methods used for Screen Printing

In actuality, there are three distinct methods of screen printing process. We will discuss each process step by step in a brief here.

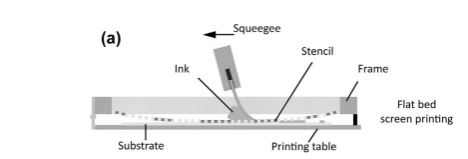

Flate to Flate Method:

The printing plate and printing substrate are both smooth in the flat-to-flat method (flatbed), which uses squeegee motions to spread ink from the printing plate via mesh pores onto the printing base—a good choice for printing on flat materials like paper, fabric, or metal sheets.

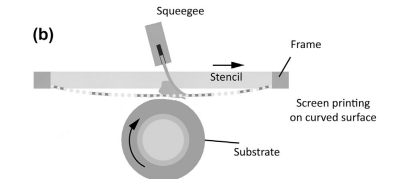

Screen printing on a Curved Surface:

This technique involves wrapping the substrate around a cylinder before covering it with the screen.

Suitable for printing on cylinders like mugs, tubes, and bottles.

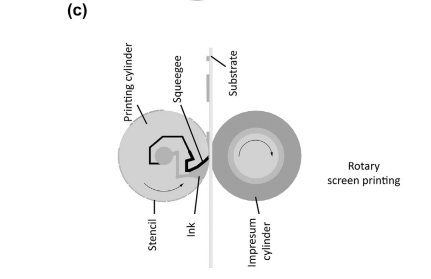

Rotary Method (round-to-round Technique)

Ink is transmitted from within via the cylindrical printing plate and onto the substrate using the round-to-round method (rotary printing), which uses a cylindrical printing screen and synchronized motion of the printing plate, printing substrate, and pressure cylinder. For the production of fabrics in large quantities, this process is effective.

4. Equipment Used for Screen Printing

A mesh screen is used in the flexible and popular printing technique known as screen printing to transfer ink to a substrate like cloth, paper, metal, or plastic. You may categorize equipment into manual (hand-operated), semiautomatic, and automatic categories.

Additional categorization of the apparatus might be done in accordance with its design, intended use, the expected number of colors each cycle, size, and other factors. The following is a list of the standard tools frequently used in screen printing:

Screen frames:

This holds the mesh screen firmly in place and is commonly constructed of wood or aluminum. Both of these materials have benefits and drawbacks. Typically constructed of aluminum or wood. Because of their longevity and resistance to warping, aluminum frames are favored.

Mesh screens:

A vital part of the screen printing process is the screen mesh. These typically consist of nylon or polyester and have varying mesh densities. The number of threads per inch is referred to as the mesh count. The amount of detail that may be attained in the print depends on the mesh count (threads per inch).

While lower mesh counts allow for thicker ink deposits, higher mesh counts provide more detailed images. Higher mesh counts are utilized for finer detail while lower mesh counts are used for bold, opaque graphics.

Squeegee

A flat, rubber-bladed tool called a squeegee is used to force ink across a mesh screen and on the surface being printed. Squeegees are available in a variety of shapes, dimensions, and durometers.

Emulsion and Emulsion Coater:

The emulsion is a material that is put onto the mesh screen and is light-sensitive. When it comes in contact with water and light, it solidifies, forming the stencil for the pattern. The emulsion is applied uniformly to the screen using an emulsion coater.

5. How are the Materials Chosen for Screen Printing?

The type of design, the cloth or medium being printed on, the desired result, and financial constraints all have a role in the selection of materials for screen printing. The following are some essential components for screen printing: mesh screen, Squeegee, emulsion coater, and screen frames.

6. Advanced Screen Printing Techniques

Advanced screen printing methods use more intricate procedures and customized tools. These methods can be applied to create distinctive and detailed designs. These are a few complex screen printing strategies:

Halftone Printing:

By changing the density of tiny dots, halftone printing involves creating gradients and shading. For replicating photos or obtaining tricky color shifts, this method is frequently utilized.

Printing Process Simulation:

This technique uses a small number of ink colors, often 4 to 6, to generate full-color graphics. Creating various colors includes making a set of halftone screens for each color and overlapping them.

Four-Color Printing Process

This process, also referred to as CMYK printing, makes use of only four ink colors—Cyan, Magenta, Yellow, and Black—to create full-color images. It is frequently employed in industrial printing.

Discharge Printing:

Using discharge ink, the dye from dark-colored materials is discharged, producing a light-colored pattern. Dark clothing is frequently utilized to create supple, breathable prints.

Water Printing:

Environmentally friendly and giving off a delicate hand feel are water-based inks. When a vintage or weathered look is required, they are frequently employed for printing on light-colored fabrics.

Printing using gel

Gel inks can be employed to give prints a raised or three-dimensional appearance since they have a thicker consistency. They are frequently employed to create unusual effects or to give definition to designs.

7. Application of Screen Printing Technique

Screen printing is a flexible printing method that may be used on a variety of items and materials. Following are a few typical uses of screen printing:

Textiles and apparel

Some of the most well-liked uses for screen printing are t-shirts, hoodies, hats, and other clothing items. It is employed for apparel advertising, branding, personalized designs, and team uniforms.

Photo by Đồng Phục Hải Triều on Unsplash

Art prints and posters:

High-end posters, fine art prints, and limited-edition works of art are frequently produced using screen printing. It enables vivid colors and minute details.

Banners and signage

Signage, banners, and decals may be made using screen printing that is strong and resistant to the elements. It is frequently employed for educational displays and outdoor advertising.

Packages and labels:

Labels are printed using screen printing on a variety of packaging materials, such as bottles, jars, tubes, and boxes. It offers a neat, businesslike appearance.

Glass and ceramics:

Ceramics, glassware, as well as other promotional items can be customized with screen printing. It may be employed to create brand products or produce unique designs.

Circuit Boards and Electronics

In the electronics sector, conductive inks and solder pastes are applied to circuit boards using screen printing.

Sporting Goods:

Screen printing is a technique used to decorate sporting goods including helmets, balls, and athletic wear with logos, numbers, and other patterns.

Automobile Components

Labels, directions, and patterns are added using screen printing to automobile components and tools.

8. Advantages and Limitations of Screen Printing

A popular printing method with its own set of benefits and drawbacks is screen printing. Following are some crucial ideas to keep in consideration:

Benefits:

Screen printing is versatile because it may be used in a wide range of materials, including paper, glass, ceramics, plastics, metals, and textiles (such as garments and fabrics).

Screen prints are frequently long-lasting and sturdy, making them perfect for objects that will require much usage or wear.

Bright Colours:

It is capable of producing bright, opaque colors, that are crucial for graphics that have to be outstanding.

Cost-Effective for Massive Orders:

Screen printing becomes quite affordable for large production runs once the screens have been set up. Because of this, bulk printing prefers to use it.

Specialty Inks and Effects:

Specialty inks like metallic, glow-in-the-dark, and more are available for use with screen printing. Foiling and embossing are two other techniques it makes possible.

Customization & Personalization:

Because it's simple to make bespoke designs, it's popular for producing personalized products like branded garments or promotional goods.

Ink Layer Thickness:

When using screen printing, it is possible to produce ink layers that are fairly thick, which can be essential for producing specific sensory or visual effects.

Limitations:

Complicated Setting: In comparison to digital printing, screen printing necessitates a more complex setting handle, which includes making screens along with setting up registration.

Restricted Quality:

It can be difficult to get outstanding detail with screen printing, especially on tiny or extremely detailed designs.

High Starting Expenses for Short Processes:

Since setting up screens can be costly, the cost per unit for short print runs might be high.

Not a good technique for photographic images:

Although halftone printing techniques can be employed, screen printing is not the greatest technique for replicating photographic or highly detailed pictures.

9. Future Trends and Innovations

Following are some basic innovations in screen printing. Let’s discuss each in some detail here.

Developments in digital printing:

Digital printing technology will continue to advance, gaining higher resolution, faster speeds, and more color options. This makes it possible to create intricate and precise designs.

Practises for Sustainable Printing:

There is a growing market for environmentally friendly and sustainable printing techniques, which has prompted the creation of water-based inks, eco-solvent inks, and other green printing options.

Additive manufacturing and 3D printing

The development of 3D printing technology has made it possible to produce intricate and unique items from a variety of materials, including plastics, metals, ceramics, and even foodstuffs.

Integration of Augmented Reality (AR):

In order to develop interactive and dynamic printed materials, mixed reality and printing technologies are being combined. This might transform marketing, packaging, and instructional materials.

Creative Packaging

Printing technologies are being leveraged to develop intelligent and engaging package alternatives, that could incorporate NFC tags, QR codes, and other innovations that offer more experiences or information.

Printing Electronics

establishment of printing techniques and useful links for making sensors, circuits, and components. Wearables, flexible screens, and IoT devices can all benefit from this.

Printing with Nanotechnology:

Nanomaterials have been employed to improve printed goods' conductivity, toughness, and UV resistance.

Printing with artificial intelligence (AI)

The printing process is being improved and optimized, from design conception through manufacturing, with the use of AI-driven design tools and automated processes.

Biodegradable substrates and inks

strive to create biodegradable or recyclable inks and substrates to lessen their negative effects on the environment.

10. FAQ

What is currently prominent in printing?

The application of nanomaterial for enhancement of qualities including conductivity, UV resistance, and resilience by the incorporation of nanoparticles in ink compositions.

What is the printing industry's future?

According to IBISWorld statistics, the print sector will keep growing for the next few decades. The market for printing in the US is expected to increase by 1.6% in 2022.

What screen printing innovation is most recent?

With the introduction of 3D printing technology, the printing sector has experienced a revolutionary shift. The procedures for product design, prototyping, and manufacturing have all been transformed by this disruptive breakthrough.

11. Conclusion

An adaptable and established printing technique, screen printing enables the creation of high-quality, bright, and long-lasting graphics on a variety of surfaces. It is used in fields including art, clothes, signage, and marketing materials. Knowing how screen printing works gives you a peek into the complex and imaginative domain of printing, wherein art and science converge to create breathtaking visual effects.

Moreover, advanced technology such as 3D printing, and nanomaterial is just reframing the screen printing sector. Screen printing, on the other hand, is a fundamental technology in the realm of printed electronics. Do you have any other thoughts about this blog? Just let us know by commenting below.