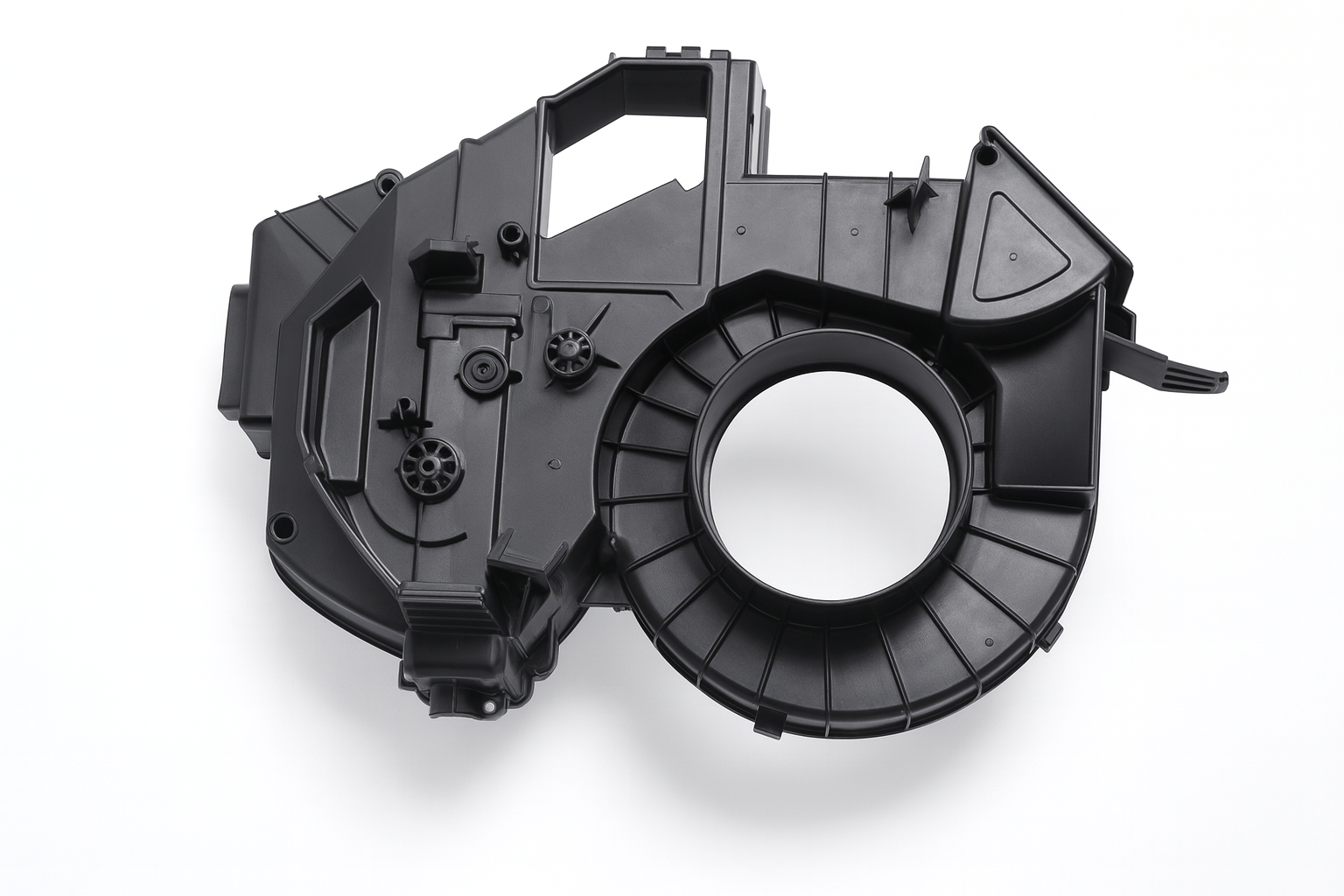

Manufacturers often face challenges in optimizing custom plastic parts production. CNC machining provides precision, flexibility, and efficiency, revolutionizing the industry.

Using advanced technology, CNC machining has become a go-to method for producing complex plastic components. It offers advantages like tight tolerances and rapid prototyping, bridging the gap in manufacturing solutions.

Understanding the benefits and applications of CNC machining can help you make informed decisions. Let’s explore various aspects of using CNC for custom plastic parts.

What Makes CNC Machining Ideal for Complex Plastic Components?

Complex designs require precision and adaptability. CNC machining excels in producing intricate plastic parts with exact specifications.

CNC machining utilizes computer-controlled systems to craft complex geometries, unlike traditional methods. This precision is crucial for industries requiring tight tolerances, such as aerospace and medical sectors.

Dive Deeper into CNC Machining for Complex Components

CNC machining is especially valuable for parts that demand precision cuts and unique shapes. The machinery’s ability to generate intricate designs surpasses manual manufacturing methods. For example, in medical devices where each piece must meet strict standards, CNC technology delivers on precision without sacrificing speed. This makes it a preferred method for components requiring excellent material consistency and structural integrity.

Without employing CNC machining, designs with fine details and sharp angles might not achieve the desired quality. Complex components produced using CNC technology ensure less human error and a more efficient workflow. Utilizing CAD software and CNC machines, manufacturers can create prototypes swiftly, expediting testing and approval phases in the development cycle.

Which Plastic Materials Deliver the Best CNC Machining Results?

Not all plastics are created equal when it comes to CNC machining. Specific materials stand out in their performance and finish quality.

Materials like ABS, acrylic, and polycarbonate often yield the best results in CNC processes. They provide the strength, clarity, and smooth finishes required for high-performance parts.

Dive Deeper into Materials Suitable for CNC Machining

ABS is known for its durability and ease of machining, making it perfect for robust parts. Polycarbonate, on the other hand, offers transparency and is less prone to cracking under stress, ideal for clear components like lenses. Acrylic provides exceptional aesthetic appeal and is used in applications demanding high optical clarity. Understanding each material’s properties helps in choosing the right plastic for specific applications. The choice of material can impact machining efficiency, part longevity, and overall quality.

Material selection is crucial as it influences machining parameters such as speed, tool wear, and surface finish. Different plastics respond uniquely to cutting forces and heat generation during machining. Leveraging material properties enables the production of parts suited for demanding environments, reducing the need for post-processing.

How Do Design Considerations Impact CNC Plastic Part Quality?

Design impacts the success of CNC-produced plastic parts. It involves understanding both the functional and aesthetic requirements.

Design choices like geometry, tolerances, and surface finishes determine part quality. Proper design ensures compatibility with CNC methods, optimizing production efficiency.

Dive Deeper into Design Impacts on CNC Quality

In designing CNC plastic parts, considering machine capabilities is vital. Designs should complement the strengths of CNC machining, such as its ability to maintain consistent tolerances. Overcomplicating designs may hinder the production process and escalate costs due to increased tooling complexity and longer processing times.

Thoughtful design impacts cycle times and overall lead times. Integrating standarized features simplifies machining operations, reducing setup complexities. Ensuring ease of machinability will enhance part reliability and minimize defects. Well-planned designs optimize material utilization, support sustainable practices, and reduce waste. Utilizing software simulations during design phases can preemptively identify potential machining issues, facilitating error-free production.

When Should You Choose CNC Machining Over Injection Molding?

Choosing between CNC and injection molding involves understanding your product’s needs and production goals. Specific factors guide this choice.

CNC machining is ideal for lower volumes, intricate designs, or when material certifications are necessary. Injection molding excels in high-volume production.

Dive Deeper into Choosing CNC Machining Over Injection Molding

Selecting CNC over injection molding can be advantageous for projects with detailed designs or small production runs. CNC provides flexibility in design modifications, making it suitable for prototype development where frequent design changes are anticipated. Additionally, for industries where material traceability and certifications are critical, such as medical and aerospace, CNC machining offers excellent reliability.

Consideration of setup and tooling time further supports choosing CNC machining for specialized projects. Unlike injection molding, which requires upfront tooling costs and setup time, CNC machining begins production swiftly once programmed. This characteristic reduces production delays and supports tight project timelines. CNC is more adaptable, allowing late-stage changes that would otherwise be complex with molded parts.

How Can CNC Machining Reduce Lead Times for Plastic Prototypes?

Short lead times are crucial for competitive advantage. CNC machining significantly reduces prototype development time.

CNC offers fast setup and execution, enabling quicker prototype production. This accelerates design validation, streamlining the development cycle.

Dive Deeper into Lead Time Reduction with CNC Machining

The agility of CNC machining lies in its capability for rapid revisions and adaptations. When creating prototypes, quick turnaround times are essential. CNC allows for immediate transitions from design tweaks to production without extensive delays. The technology supports on-demand alterations, essential for refining design and ensuring market readiness.

Faster lead times contribute to increased production efficiency and reduced time-to-market. CNC machines equipped with advanced programming facilitate the swift processing of intricate design schemes directly from CAD drawings. This minimizes the cycle of prototype testing and adjustments, accelerating the design approval process. Enhanced responsiveness aids in addressing market demands promptly, aligning production output with industry pace and client expectations.

Conclusion

CNC machining optimizes plastic parts production with precision, flexibility, and efficiency. It’s ideal for complex designs, rapid prototyping, and industries demanding exact standards.

CNC machining stands out as a key player in optimizing custom plastic parts production. Its capacity to handle complex designs, offer flexibility in production volumes, and ensure precision make it indispensable. By understanding material properties and design principles, CNC machining maximizes efficiency and quality. Its adaptability in the face of rapid changes underscores its role as a preferred manufacturing method in industries heavily reliant on innovation and precision.

Whether it's minimizing lead times or choosing the right material, CNC machining supports strategic production processes, empowering businesses to stay competitive. Embracing this technology leads to better performance, quicker market entry, and greater overall success.