Metal parts often develop stress during machining, leading to warping and premature failures. Without proper heat treatment, even the most precisely machined components can disappoint in the field.

Annealing is a controlled heating and cooling process that relieves internal stresses in metals, making them more ductile and stable. This treatment prevents warping in complex parts, extends component lifespan, and ensures dimensional stability in precision applications.

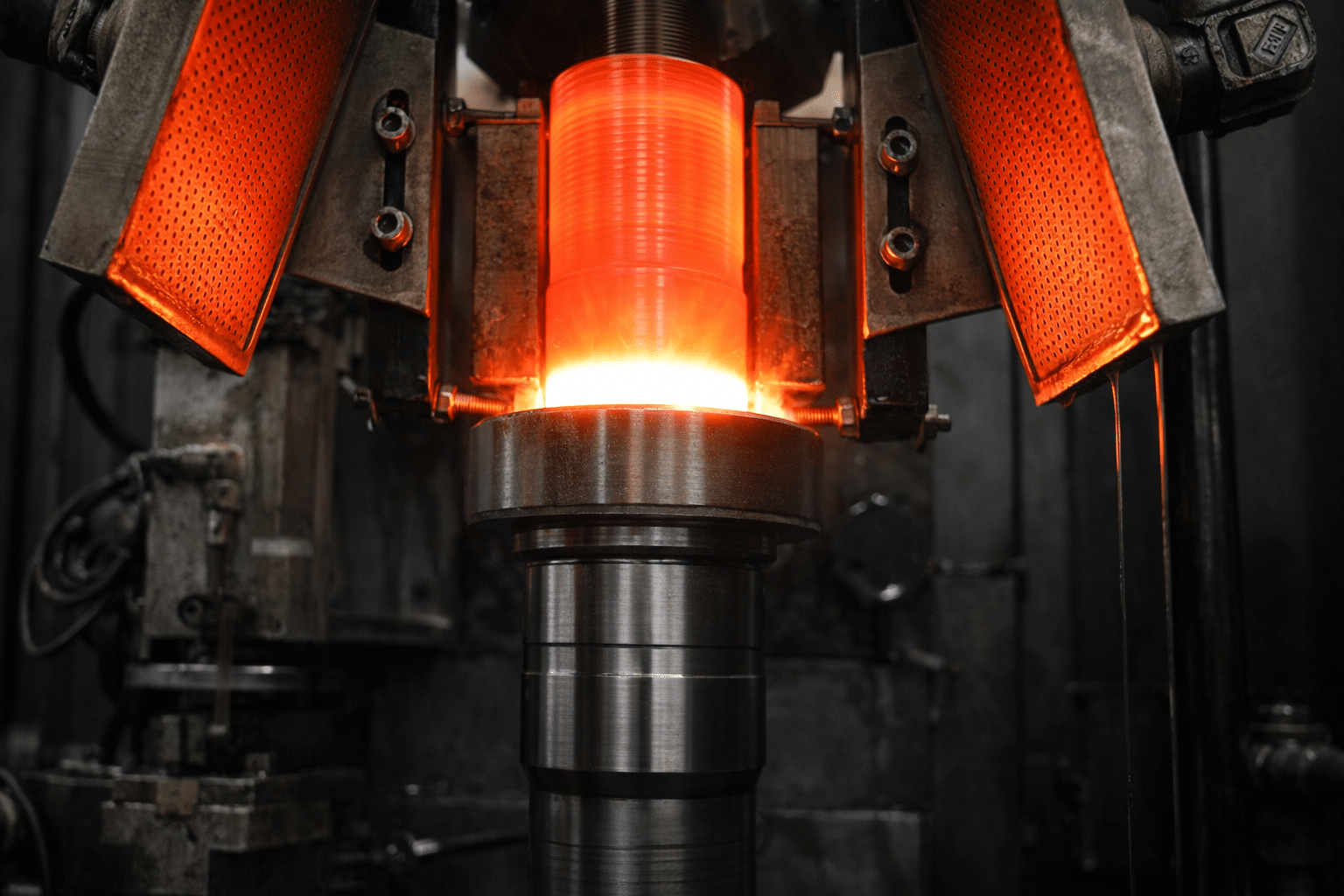

Metal components are being heat-treated in an industrial furnace

In our factory, we've seen countless parts transformed through proper annealing. Let me share what I've learned about this vital process and how it can enhance your next machining project.

What happens to metal properties during the annealing process?

Have you ever tried to bend a paperclip repeatedly? It becomes brittle and snaps. Metal components face similar issues after machining, with internal stresses making them unpredictable.

During annealing, the metal is heated to a specific temperature and cooled slowly, allowing its crystalline structure to reorganise. This process reduces hardness, eliminates internal stresses, increases ductility, and restores workability to metals that have become work-hardened.

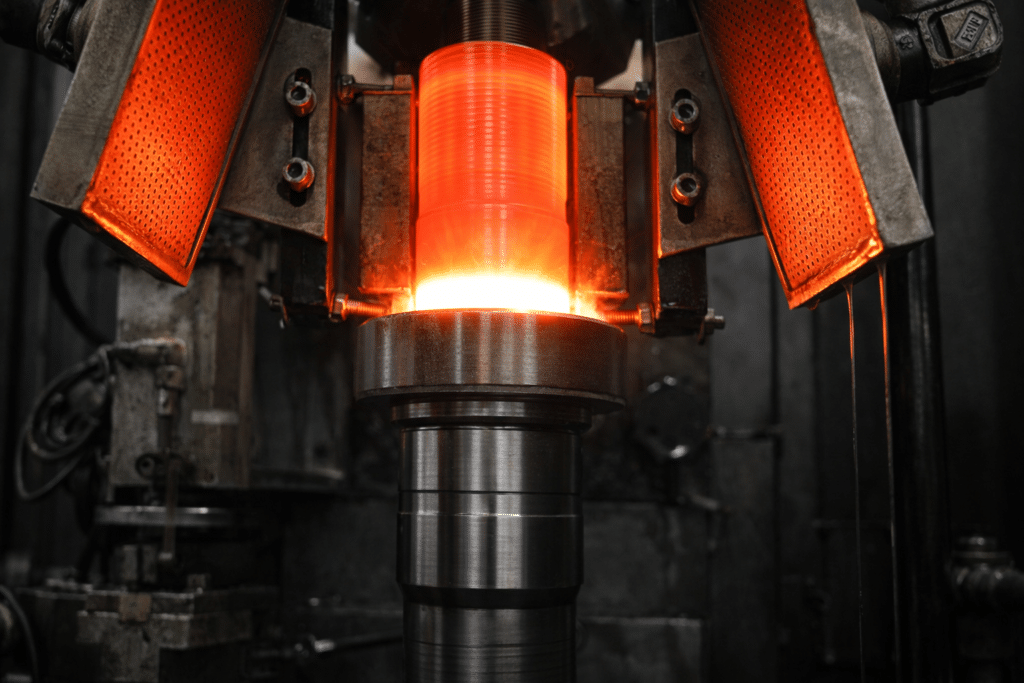

Before and after comparison of the metal grain structure

Annealing fundamentally transforms the microstructure of metals through three key phases. First, the recovery phase occurs as we heat the metal to its critical temperature, relieving internal stresses without changing the metal's crystalline structure. Then comes recrystallisation, where new strain-free grains form, replacing the distorted structure caused by cold working. Finally, the grain growth phase allows these new crystals to enlarge.

The cooling rate is just as important as the heating. Too rapid cooling can reintroduce stresses, while properly controlled cooling ensures optimal grain structure. Different metals require specific annealing temperatures and cooling profiles. For example, copper typically anneals between 700-900°F, while stainless steel might require 1900°F or higher.

The results are measurable and significant. Hardness typically decreases by 15-50% depending on the material, while ductility can increase by 30-200%. These changes directly impact machining operations, allowing for more aggressive cutting parameters without chatter or tool breakage.

Why is annealing critical for precision CNC-machined parts?

Your precision components are warping after machining, costing time and money in rework and rejections. Why risk project delays and reputation damage with unstable parts?

Annealing stabilises machined components by eliminating residual stresses that would otherwise cause warping over time. For precision applications, this process ensures that tight tolerances are maintained throughout the component's service life, particularly in parts with complex geometries.

Comparison showing improved dimensional stability

In our precision machining operations, annealing serves as a critical intermediate step that directly impacts final product quality. Complex geometries with varying thicknesses are especially prone to stress concentration during machining. Without proper annealing, these stresses can lead to unpredictable dimensional changes days or even weeks after the part leaves our facility.

The numbers tell the story: annealed components typically show 70-90% reduction in internal stresses compared to untreated parts. This translates to significantly improved dimensional stability, especially in parts with tight tolerances. We've documented cases where unannealed precision components drifted out of specification by 0.003-0.005 inches within weeks of machining, while identical annealed parts maintained tolerances within 0.0005 inches over years of service.

Beyond dimensional stability, annealing improves machinability for subsequent operations. When manufacturing vacuum chamber components, for instance, we often perform an intermediate anneal before final precision machining. This approach allows for more aggressive cutting parameters in the roughing phase while ensuring the stability needed for the finishing phase.

For thin-walled components like custom automotive heat shields or precision medical device housings, annealing between forming operations prevents work hardening from causing cracks or tears. The improved ductility allows for more complex geometries that would otherwise be impossible to achieve.

When should you specify annealing in your machining project?

You're experiencing unexpected failures in your components, and your engineers can't figure out why. Could unresolved internal stresses be silently undermining your product's reliability?

Annealing should be specified whenever a component will undergo substantial material removal, multiple machining operations, or when the final application requires consistent mechanical properties. Parts that will experience thermal cycling in service, components with thin walls, or those machined from work-hardened stock all benefit significantly from proper annealing.

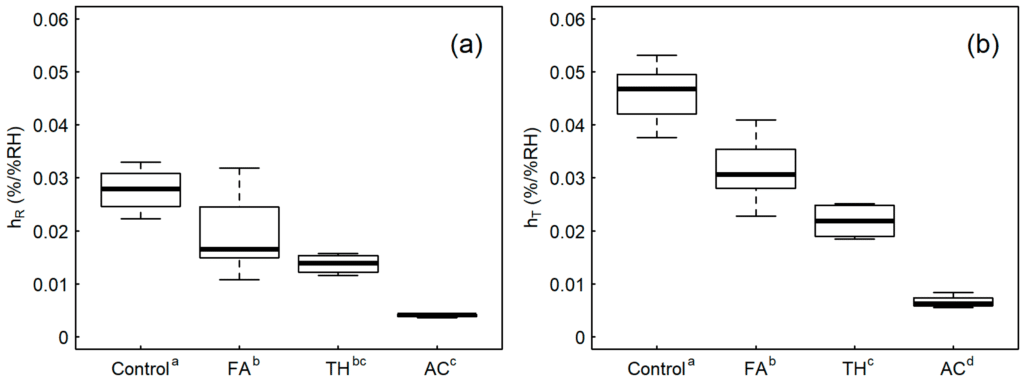

Decision tree showing when to incorporate annealing

Based on our extensive experience, annealing decisions should be driven by both material characteristics and application requirements. The most obvious candidates are components that have undergone severe cold working or substantial material removal, as these processes introduce significant internal stresses. For example, when we machine sailboat fittings from bar stock that's been cold drawn, an intermediate anneal is essential to prevent stress corrosion cracking in the marine environment.

Timing is also crucial in the annealing decision. For complex parts that require multiple setups or machining operations, strategic annealing between operations can prevent cumulative stress buildup. We recently completed a project for semiconductor vacuum chambers where we performed controlled annealing after rough machining but before the final precision operations, resulting in final dimensions that remained stable within 0.0002" even after months of thermal cycling in service.

Material selection also influences annealing requirements. Highly alloyed steels, nickel-based superalloys, and certain grades of stainless steel are particularly prone to work hardening during machining. For these materials, we often recommend a specific annealing schedule that's integrated into the manufacturing process plan.

The cost implications must be balanced against performance requirements. While annealing adds processing time and cost, it frequently prevents much costlier failures in service. For critical components in aerospace or medical applications, the insurance provided by proper annealing far outweighs the additional processing expense, often reducing warranty claims and field failures by 30-50%.

Which industries require annealed components and why?

Your competitors are delivering more reliable products while you're still struggling with unexplained failures. What's their secret to consistent performance in demanding applications?

Industries with high reliability requirements—aerospace, medical, semiconductor, and automotive—regularly specify annealed components. These sectors require parts that maintain dimensional stability under thermal cycling, resist fatigue failure under repeated loading, and provide predictable performance throughout extended service lives.

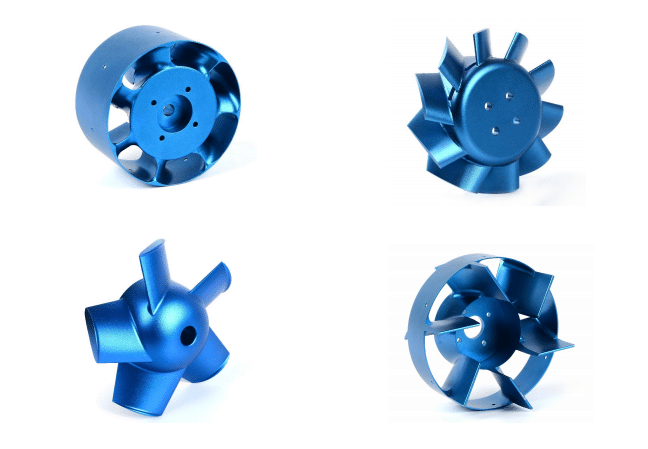

Aerospace, medical, and automotive annealed components

The aerospace industry represents one of the most demanding applications for annealed components. When machining turbine components or structural elements for aircraft, we follow rigorous annealing protocols that must comply with standards like AMS2750 for heat treatment. These parts often experience extreme temperature variations during service—from sub-zero temperatures at high altitudes to hundreds of degrees near engine components. Without proper annealing, these thermal cycles would quickly lead to dimensional changes or even catastrophic failures.

In the medical device industry, biocompatibility combines with precision requirements to drive annealing specifications. Surgical instruments and implantable devices must maintain exact dimensions while resisting corrosion in the body's hostile environment. We've produced components for medical robots where annealed stainless steel parts maintain positioning accuracy to within 0.0005" even after thousands of sterilization cycles.

The semiconductor industry presents unique challenges that make annealing essential. Vacuum chambers and wafer handling components must maintain dimensional stability while also meeting stringent cleanliness requirements. For these applications, we often perform specialized atmosphere-controlled annealing that prevents surface oxidation while still relieving internal stresses.

Automotive applications, particularly in high-performance and racing sectors, benefit greatly from annealed components. Engine components, suspension elements, and braking systems all experience significant thermal and mechanical stresses. When we machine custom racing components, the annealing process is carefully documented and certified, as it directly impacts both performance and safety.

Marine applications present the combined challenges of corrosion resistance and structural integrity. Sailboat winch components and custom fittings for ocean vessels must withstand both corrosive environments and significant mechanical loads. Properly annealed components show up to 200% greater resistance to stress corrosion cracking compared to their unannealed counterparts.

Conclusion

Annealing transforms ordinary machined parts into reliable, stable components that maintain precision throughout their service life. By incorporating this critical process into your manufacturing plan, you'll gain longer component life, improved performance, and the confidence that comes from predictable material properties.