There is no doubt, that technological improvements have had a revolutionary impact on the manufacturing industry and production processes. The creation of portable computing, CNC machining, and manufacturing, CNC milling services, portable sensors, wireless communications, etc. has drastically altered the production processes over the last three decades. The overall objective of Modern CNC machine tool systems is improving accuracy and productivity at the same time.

A CMM is also known as a coordinate measuring machine plays a vital role in maintaining workflow, making it a significant instrument in the manufacturing process. Yet, changes in the CMM industry have been more evolutionary than revolutionary.

The traditional approach requires the use of optical comparators or hand instruments for measuring objects. These technologies, however, require expertise but are vulnerable to many faults. The usage of a CMM machine is the alternative approach.

The instrument that measures the geometry of the physical object is a coordinate measuring machine or CMM. CMMs use a probing system to detect discreet points on the surfaces of objects.

According to analysis, the market for coordinate measuring machines (CMMs) is predicted to grow from an estimated USD 2.8 billion in 2021 to USD 4.3 billion by 2026, at a CAGR of 8.8% over that time.

In this article, you will explore about CMM machine; how it revolutionized the manufacturing process? How does it work? The perk of reading this article is you will get to know CMM machine benefits and limitations in the production processes. Thus, Keep on reading. let's get straight into it.

Photo by Greg Rosenke on Unsplash

Role of CMM machine

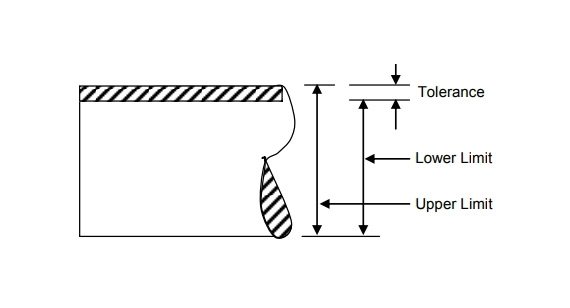

The dimensions and geometrical features of the parts are necessary when producing prototypes or actual products. This is because mistakes with the dimensions might put the entire production process in danger. So a high tolerance measuring equipment CMM machine was developed to do away with that.

Most frequently, CMMs are used to test a part or assembly to see if it adheres to the original design intent. The dimensions of manufactured components are checked using CMMs as part of workflows for quality assurance or quality control in order to prevent or address quality issues.

You may now experience inspecting areas that would typically be challenging to measure with regular instruments due to the accurate measurement of objects for design, assessment, testing profiling, and reverse engineering.

- Batch examination and reporting.

- batch analyses (SPC).

- casting machine proofing, marking out, and casting.

- a consulting service to help with the creation of reliable dimensioning and measurement techniques throughout the design phase of new projects.

- Referencing one another

- fault detection using testing, and many more

The CMM continues to be a very adaptable measuring tool, with its measurement capabilities often only being limited by its physical dimensions, sensor configuration, and accuracy level. CMMs have improved in speed, accuracy, and programming ease during the past few decades.

CMM revolutionize the production

Recently developed general-purpose CNC machining and manufacturing tool systems are reaching improved accuracy and increased productivity at the same time. A lot of manufactured items that previously needed a number of specialized machines can now be totally machined on one of these high-performance CNC machining service tool systems because of the increasing adaptability of such machine tools.

In order to ensure the quality of the work-in-progress (WIP) or final parts, a quick inspection of the critical machined features is necessary immediately the following machining before sending the part to the next machining process. This is because sophisticated geometric features are created in one machining process in such a new machining system.

Thus, Manufacturers of CMMs are constantly improving their products, making constructions stiffer, lighter, and thermally adjusted for operation outside of their formerly customary temperature-controlled quality rooms. Scanning probe advancements, such as 5-axis technology, have made it possible for CMM machines to measure even the most complicated geometries while producing significantly more measurement data than conventional gauging approaches and with a great deal more flexibility.

It is well known that coordinate measuring machines (CMMs) are effective tools for inspection and measurement. The creation of an automated inspection planning system is necessary for maximizing the use of CMMs. The overall cost of the finished product is reduced by using a computer-aided inspection planning (CAIP) system to reduce the total time required for the inspection process.

Automated CMM inspection

The release of TEMPO, a robotic part loading system for coordinate measuring machines (CMMs), by Hexagon's Manufacturing Intelligence division enables manufacturers to sustain inspection productivity without the need for manual intervention.

The efficient automated part loading system known as TEMPO maximizes operational capacity and boosts the coordinate measuring machine (CMM) output.

TEMPO offers autonomous, interruption-free measurement. TEMPO enables businesses to continue production even when CMM operators are not available, regardless of whether you have midnight production requirements or staff members need to focus on other crucial activities. Every extra shift is worked by TEMPO.

The greatest flexibility is the goal of this pre-made solution. The easy reconfigurability of TEMPO makes it suitable for use on both new and used CMMs and any new parts that need to be inspected. The system is created to be simple and efficient, and it just takes a little training to start using TEMPO to improve workflows.

Why do I require it today?

You should be aware of why they are applicable to all industrial processes. Understanding the operational differences between the traditional and new methods is necessary for providing an answer.

There are numerous drawbacks to measuring parts traditionally. For instance, the operator examining the parts needs expertise and skill. Insufficient representation of this could result in the supply of inadequate parts.

The complexity of the components generated in this century is another factor. The development of more complicated elements is a result of technical advancement. A CMM machine is therefore more appropriate for the process.

Use of CMM Machine

There are two basic types of CMM machines in terms of measurement methods. There is a type that measures the tool portion using a contact mechanism (touch probes). The second type's measurement system employs alternative techniques like cameras or lasers. The sizes of the parts it can measure can also vary. There are certain models (of automotive CMM equipment) that can measure parts bigger than 10 meters.

A CMM can be operated manually by moving the probe to the part that needs inspection with a joystick or by hand. The measurements are then taken by the machine and sent to the computer program. There are certain things you need to consider while using a CMM machine that is mentioned below.

- You must first decide the measurements you want to take, typically using drawings or a measurement plan as a guide.

- It will be necessary to calibrate the suitable probe and fix it to the measuring arm.

- To ensure exact alignment, align the axis and measure the reference objects.

- Set a selected Z-axis and align the component or object to be measured.

- Obtain the necessary measurements.

- Using the software, create the necessary reports or compare the data as needed.

Benefits and limitation

- In contrast to manual tools like micrometers, vernier calipers, or height/depth gauges, coordinate measuring machines (CMMs) are capable of measuring in three dimensions (X, Y, and Z), whereas conventional manual tools can only measure in one direction at a time.

- Using the points obtained from contact with the measuring piece, CMMs precisely monitor a probe tip in 3D space and generate dimensional measurements through shape building. For shape, form, and warpage examination, an even greater number of points can be collected over a broader region on the part to map the surface and compare it to CAD data.

Limitations

- Using a probe can cause parts made of soft materials, such as rubber and elastomers, to collapse. The error will result from this, which will be visible upon digital examination.

- Different types of probes are used by CMM machines, and the best probe must be chosen. The part's dimension, the needed design, and the probe's capability all play a significant role in choosing the best probe.

What kind of company should I hire to provide CMM Inspection Services?

Make sure they use the most recent Co-ordinate Measuring Machine and Inspection Technology to offer BS EN ISO/IEC 17025:2005 UKAS Accredited Metrological Testing and Reporting in addition to inspection services. For each of their unique uses, precision-engineered components must be accurate.

Engineers must have extensive measurement experience and be highly qualified in a variety of industries, including aerospace, automotive, defense, healthcare, packaging, and pharmaceuticals. To ensure that employees continue to work at a high level that meets industry standards, the organization must continue to invest in the newest software and development training.

The Final thoughts

The CMM machine is reframing the manufacturing processes. As compared to traditional measurement tools the CMM machine is a state-of-the-art method for accuracy and precision measurement by using a laser or manual probe method.

The BaiChuan is one of the leading companies in CMM inspection and measurement. We have huge CNC machining and manufacturing service including reverse engineering, CNC milling prototypes, CNC milling services, product design, CNC short-run production, and CMM inspection and measurement services.

We have more than 20 CNC machining service centers. We check all the product raw materials from the initial stages and deliver products to our clients with full safety. Thus, in inspection and measurement, we might be the best choice. If you have any other views about this blog, let us know by commenting below.