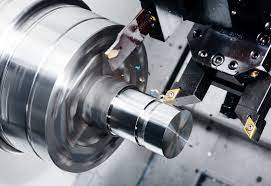

Are you struggling with inconsistent machining results and soaring production expenses? Custom tooling could be the solution you've overlooked, offering precision that standard tools simply cannot match.

Custom CNC lathe tooling can dramatically improve performance by addressing specific machining challenges unique to your application. These purpose-built tools can reduce cycle times by up to 40%, extend tool life, and enable complex operations impossible with off-the-shelf options, directly impacting your bottom line.

In our years of CNC machining experience, I've witnessed countless operations transformed through the strategic implementation of custom tooling solutions. The difference between standard and custom tooling isn't just about performance—it's about reimagining what's possible in your production process. Let's explore how custom tooling can revolutionize your CNC lathe operations.

What Makes Custom CNC Tooling Different from Standard Options?

Does your current tooling force you to make compromises in your manufacturing process? Standard tools are designed for general applications, but custom tooling is engineered specifically for your unique challenges.

Custom CNC tooling differs from standard options by being precisely designed for specific materials, geometries, and cutting conditions. Unlike generic tools that offer acceptable performance across multiple applications, custom tools optimize every aspect of the cutting process for your exact requirements, maximizing efficiency and output quality.

Standard tools versus custom-engineered solutions

Custom tooling represents a fundamental shift in manufacturing philosophy. Rather than adapting your processes to work within the limitations of standard tools, custom solutions conform to your specific needs. I remember working with a marine components manufacturer who struggled with exotic alloys using standard tooling. After implementing custom carbide tools with specialized geometries and coatings, their cycle times decreased by 35% while tool life doubled.

The key differences between standard and custom tooling include geometric precision, material selection, and cutting parameter optimization. Custom tools can incorporate complex features like specialized chip breakers, unique approach angles, or multi-function capabilities that standard tools cannot provide. For example, when machining vacuum chamber components, we designed a custom boring bar that combined multiple operations into one tool, reducing cycle time by nearly 40% and eliminating tool changes that introduced potential errors.

Another significant advantage is the ability to address specific material challenges. While standard tools might perform adequately across common materials, custom tooling can be optimized for difficult-to-machine alloys like Inconel, titanium, or hardened steels. Through careful selection of substrate materials, coatings, and edge preparations, these tools can maintain sharper cutting edges longer, even under extreme conditions.

| Aspect | Standard Tooling | Custom Tooling |

|---|---|---|

| Design Focus | General applications | Specific applications |

| Performance | Acceptable across materials | Optimized for specific materials |

| Initial Cost | Lower | Higher |

| Long-term Value | Limited optimization | Significant cost savings |

| Cycle Time | Baseline | Typically, a 20-40% reduction |

| Tool Life | Standard | Often 2-3× longer |

| Complex Operations | Limited capabilities | Enables unique solutions |

How Should You Specify Requirements for Custom CNC Lathe Tools?

Are your manufacturing challenges so unique that off-the-shelf tooling simply can't deliver the results you need? Properly specifying your requirements is the crucial first step toward a successful custom tooling solution.

When specifying custom CNC lathe tools, focus on your workpiece material, desired surface finish, geometric complexity, and production volume. Provide detailed documentation including part drawings, material specifications, and current performance metrics. The more comprehensive your requirements, the more effective your custom tooling solution will be.

Engineering team reviewing custom tooling requirements

Developing clear specifications for custom tooling requires a systematic approach that considers your entire manufacturing process. In my experience working with automotive clients, the most successful custom tooling projects begin with thorough documentation of current challenges. I remember helping a client who needed to machine complex transmission components with extremely tight tolerances. By analyzing their existing process first, we identified that tool deflection during specific operations was causing dimensional variations.

The specification process should always begin with your workpiece material characteristics. Different materials demand different cutting edge preparations, rake angles, and clearances. For example, when machining aerospace-grade titanium alloys, we specify custom tools with positive rake angles, sharp cutting edges, and specialized coatings to manage heat generation. Conversely, when working with hardened steels, negative rake angles and robust edge preparations typically yield better results.

Production volume considerations are equally important when specifying custom tooling. High-volume production justifies more specialized and potentially more expensive tooling solutions that maximize tool life and minimize cycle time. For smaller production runs, the focus might shift toward flexibility and quick setup. We've developed modular custom tooling systems for clients who frequently change between similar parts, allowing them to maintain efficiency while avoiding the expense of completely separate tooling packages.

| Specification Element | Details to Include | Impact on Tool Design |

|---|---|---|

| Workpiece Material | Exact alloy, hardness, condition | Influences substrate, coating, edge prep |

| Surface Finish | Ra/Rz requirements, critical surfaces | Affects insert geometry and cutting parameters |

| Dimensional Tolerances | Tightest tolerances, critical dimensions | Determines tool rigidity requirements |

| Production Volume | Annual quantity, batch sizes | Influences tool durability and cost optimization |

| Current Performance | Cycle time, tool life, quality issues | Establishes baseline for improvement |

| Machine Specifications | Horsepower, rigidity, tooling interfaces | Ensures compatibility with existing equipment |

Which Materials Perform Best for Custom CNC Lathe Tooling in Different Applications?

Are you using the optimal tool materials for your specific machining applications? The choice between carbide, ceramic, CBN, or PCD can dramatically impact your productivity and part quality.

The best material for custom CNC lathe tooling depends on your specific application. High-speed steel works for simple, low-volume jobs; carbide excels in versatility; ceramics handle high temperatures; CBN is ideal for hardened materials; and PCD provides unmatched performance for non-ferrous metals and composites.

Different tooling materials for custom CNC applications

Selecting the optimal material for custom tooling involves balancing performance requirements against economic considerations. Through decades of manufacturing experience, I've found that the right material choice can transform a challenging operation into a routine one. When we started machining complex aluminum aerospace components, switching from standard carbide to PCD (polycrystalline diamond) tools increased our tool life tenfold while improving surface finish quality dramatically.

Carbide remains the workhorse material for most custom tooling applications due to its excellent balance of hardness, toughness, and cost-effectiveness. Modern carbide grades have become increasingly specialized, with micrograin structures and carefully controlled cobalt percentages tailored for specific applications. For high-temperature alloys like Inconel, we typically recommend carbide grades with higher cobalt content (10-12%) to improve fracture resistance, combined with specialized coatings like AlTiN or TiAlN that form protective oxide layers during cutting.

Ceramic tooling materials represent another frontier in custom tooling, particularly for high-speed machining of hardened materials. Silicon nitride ceramics excel in cast iron machining, while whisker-reinforced ceramics handle nickel-based superalloys at cutting speeds that would destroy carbide tools. I recall working with a client who manufactured industrial valves from heat-resistant superalloys. By implementing custom whisker-reinforced ceramic inserts, they increased cutting speeds from 300 SFM to over 1,000 SFM, transforming their production capabilities.

For the most demanding applications, superhard materials like CBN (cubic boron nitride) and PCD offer unmatched performance. CBN excels in hardened steels (45-70 HRC), cast irons, and superalloys, often allowing cutting speeds 5-10 times higher than carbide. PCD, with its unmatched hardness and thermal conductivity, revolutionizes the machining of non-ferrous metals and composites. The initial investment in these advanced materials is substantially higher, but the performance advantages—longer tool life, superior surface finish, and faster cutting speeds—often deliver compelling long-term value.

| Tool Material | Best Applications | Advantages | Limitations |

|---|---|---|---|

| High-Speed Steel | Low-volume, simple operations | Low cost, easy to customize | Limited speed and temperature resistance |

| Carbide | General-purpose, versatile | Good balance of hardness and toughness | Moderate cost, requires coating for optimal performance |

| Ceramics | High-temperature alloys, hardened materials | Excellent heat and wear resistance | Brittle, requires rigid setups |

| CBN | Hardened steels, cast iron | Superior hardness, thermal stability | High cost, limited application range |

| PCD | Non-ferrous metals, composites | Unmatched wear resistance, excellent finish | Very high cost, not suitable for ferrous materials |

How Does the Custom Tool Design Process Work with CNC Manufacturing Partners?

Wondering how to navigate the custom tool development journey with your manufacturing partner? The process requires collaboration, expertise, and attention to detail to achieve optimal results.

The custom tool design process involves collaborative problem-solving between your team and tooling engineers. Starting with requirement analysis, the process progresses through conceptual design, simulation testing, prototyping, and final implementation. The best partnerships involve continuous communication and refinement throughout each phase.

Engineering collaboration for custom tooling design

Developing custom tooling solutions is a highly collaborative process that leverages both your application expertise and your manufacturing partner's tooling knowledge. In my experience managing complex tooling projects, the most successful outcomes result from true partnerships. I remember working with a medical device manufacturer who needed to machine intricate titanium components with extremely tight tolerances. By establishing a systematic development process with clear communication channels, we created custom tooling that reduced their cycle time by 45% while improving dimensional consistency.

The process typically begins with a comprehensive requirements analysis. This phase involves gathering detailed information about your specific challenges, current performance metrics, and desired outcomes. Our engineering team works closely with clients to understand not just the immediate tooling needs but the broader manufacturing context. For example, when developing custom tooling for semiconductor vacuum chamber components, we needed to understand the entire production flow to ensure our tooling solutions would integrate seamlessly with existing processes.

Conceptual design represents the creative phase where tooling engineers translate requirements into potential solutions. This stage often involves multiple design iterations, each evaluated against performance criteria, manufacturing feasibility, and economic constraints. Advanced CAD modeling allows visualization of tool geometries and cutting dynamics before any physical prototypes are produced. We frequently use simulation software to predict chip formation, cutting forces, and potential failure modes, allowing refinement before investing in physical tooling.

Prototyping and testing provide critical validation of the design concepts. Depending on complexity and production volumes, prototypes might range from simplified test tools to full production-ready implementations. The testing phase should replicate actual production conditions as closely as possible, with careful measurement of all relevant performance metrics. I've found that structured testing protocols with clear success criteria are essential for objective evaluation. For one automotive client, we developed three different prototype tools for machining transmission components, conducting extensive testing to identify the optimal solution before proceeding to full production implementation.

| Design Phase | Key Activities | Client Involvement |

|---|---|---|

| Requirements Analysis | Document challenges, gather specifications, establish metrics | High (providing application expertise) |

| Conceptual Design | Create multiple solution approaches, evaluate feasibility | Medium (feedback on concepts) |

| Simulation & Analysis | Virtual testing, performance prediction, design refinement | Low to Medium (review of results) |

| Prototyping | Physical tool creation, initial testing | Medium (facility access, equipment availability) |

| Testing & Validation | Performance verification, quality assessment | High (operational testing, quality verification) |

| Implementation | Production deployment, operator training | High (integration into production processes) |

Conclusion

Custom CNC lathe tooling represents a strategic investment that can transform your manufacturing capabilities, not just a production expense. By partnering with experienced tooling specialists, you can develop solutions that dramatically improve performance, quality, and profitability across your operations.