Suitable to Create Your Part?

Manufacturers across the globe often explore different options to create functional parts.

They search for modern techniques to reduce their production cost, time, and energy. That's where their search comes to a halt. They need to choose between CNC and 3D printing.

Are you one of those manufacturers? Do you want to create functional parts with 3D printing or CNC machining? Of course, 3D printing can give you the quality essential for industrial-level production.

But knowing the differences between CNC and 3D printing is essential, and it can help you choose the best technique for your production line.

So let's explore CNC vs. 3D printing in today's article!

What Is CNC Machining?

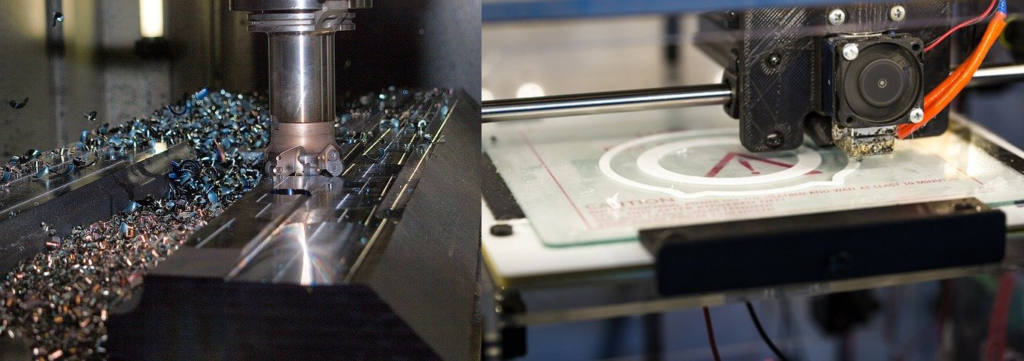

Image Source: https://pixabay.com/photos/cnc-machine-milling-drill-industry-5770325/

CNC Machining is an abbreviation for computer numerical control. It is a form of subtractive manufacturing. Thus, it has been a superior method for years.

The method dates back to the 1940s. It was in use to machine highly advanced parts that needed optimal precision. CNC machining requires cutting or subtracting from material blocks to create final products.

Nowadays, this kind of manufacturing occurs in various forms. These include carving, wire EDM, and laser cutting. Others are turning and milling.

What Is 3D Printing?

Image Source: https://pixabay.com/vectors/3d-printer-3d-printing-3d-printer-3311587/

3D printing is also called prototyping or additive manufacturing. It is among the latest fabrication mechanisms.

Until this moment, there has been significant growth in 3D printing. That's because of material and technological advancements. This form of manufacturing dates back to the 1980s.

Product developers use this method to reproduce prototypes from digital designs. Some people prefer it for its flexibility, low cost, and speed.

The 3D printing process occurs layer by layer. It comes in various technological forms. Besides, it can print many metal and polymer materials.

The two technologies have their upsides and downsides. Most are in the product development and manufacturing space. There are arguments to make to gauge an ideal method for your application or process.

But, it is vital to note that the two methods can often be complementary. They can exist side by side. To identify if these technologies can benefit your industry, here are some factors:

- Production process

- Design development

- Company culture

- Business model

For instance, machine shops can use CNC machining if they have voluminous production needs. At the same time, they can use 3D printing to create parts with complex or advanced designs or geometrics. Something that CNC machining can't do.

Can 3D Printing Become a Replacement for CNC?

Since its launch, CNC machining has proven to be the most typical method of prototyping to date. Yes, there are other new methods. But, they don't compare to this form of subtractive manufacturing even if there is co-existence.

Who knows if things will change in the future. We aren't sure as the possibilities are 50-50. 3D printing might and might not overtake CNC machining.

This form of additive manufacturing is admirable. It is already working on various tasks that CNC machines could do. But, it is only a minor task.

Moreover, the overall cost of CNC machining is minimal if you compare it with 3D printing. Most people agree that CNC processing is at its peak of development.

Some of these machines, though tiny, are mini-factories. A good number are robust in their capabilities. They can execute many tasks, and the limitations are few.

In instances when CNC machining has its downsides, 3D printing comes in to save the day. You can manufacture almost any object using 3D printers in days. But, it is typical for overlapping to occur.

CNC vs. 3D Printing - A Comparative Study!

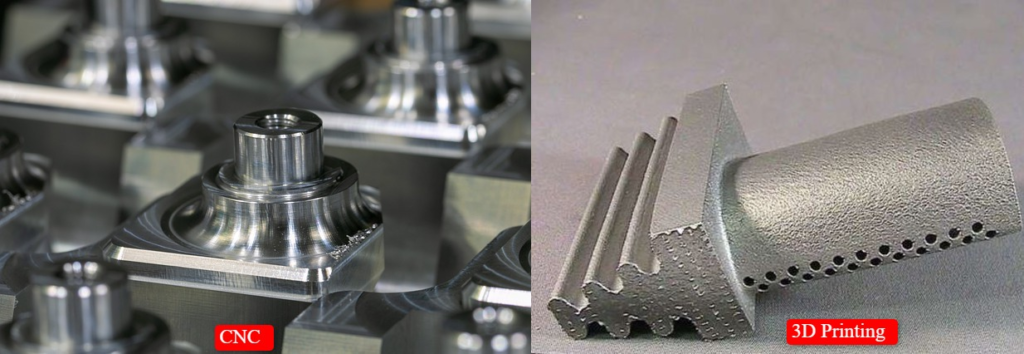

CNC machining, as part of subtractive manufacturing processes, is more popular worldwide. It offers more versatility than other manufacturing methods.

On most occasions, when someone wants a functional detail or part, CNC technology is a primary tool. It is common in engineering, testing, and evaluations.

In military terms, CNC machining and other subtractive processes are called vanguard. 3D printing and other additive processing methods are termed rearguard.

Here is how the two methods compare to each other:

1) Ease of Use

There is computer-aided software for the design that can work with 3D printers and CNC routers. The two technologies use different methods to give outputs.

CNC routers will use a method that does the opposite of what a 3D printer will do. CNC machines begin with blocks of material. Waste is all cut out and what is left is only the intended final product.

Likewise, 3D printers will begin from nothing then add layers of unique material. Thus, it forms a mass to assume the shape of the intended product design.

Sometimes, the printer's capabilities can be a limitation to flexibility and production. CNC technology produces quicker results.

2) Materials

CNC routers create heavy-duty outputs. These are made from metals with high density and high tensile strength. CNC outputs can be precision parts for production machinery, engines, and airplanes.

Also, they are used in high-intensity environments, wax, wood, and plastics. Any other material can work with CNC machining.

On the other hand, most 3D printers use an additive process. They make products from special resins, metal, and plastic, and different types of material.

The printing process uses unique materials. 3D parts might not have enough strength to use in some demanding settings. Besides, it might not work in settings for vehicles and other production machinery.

Materials used in printing 3D objects will work well when creating prototype models. For consumer-grade products for personal and domestic use will work too.

There is newer 3D technology used in producing dental and medical products. These techniques use unique FDA-approved materials. But, there are no 3D printers that can make a similar output quality as a CNC router would.

| Material | CNC | 3Dprinting |

| Stainless steel | √ | √ |

| Aluminum | √ | X |

| Brass | √ | X |

| Titanium | √ | X |

| Polycarbonate | √ | X |

| Nylon | √ | X |

| PEEK | √ | X |

| ULTEM | X | √ |

| ABS | X | √ |

| TPU | X | √ |

| ASA | X | √ |

| PLA | X | √ |

3) Cost

The differences between these two forms of manufacturing make price comparison quite tricky. Definitions of typical units will vary between jobs, materials, and customers.

Comparisons will be in general terms. If using a CNC machine to make a specific part, a small quantity comes at a high unit cost. Producing large batches is cheaper with CNC machining.

For this reason, CNC machining is excellent for mass production. In 3D printing, each unit will cost the same despite the batch size.

If you produce a small quantity of an item, the total cost of each unit you make will represent an advantage. But, if you are producing larger batches of an item, the total cost for each unit can be difficult.

With CNC machining, a product's unit cost will increase as per the precision and complexity of its output. The high price of complex CNC outputs stems from the increased number of tool paths needed.

Also, the small cutter you use and the time needed to finish the job matter.

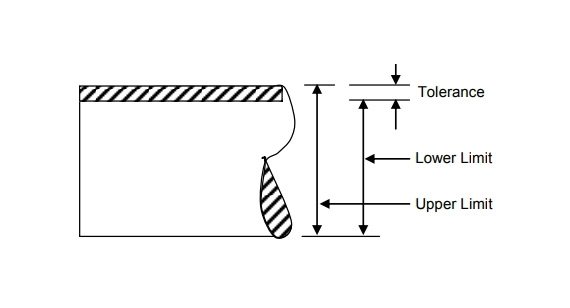

4) Accuracy

CNC machining offers superior surface qualities. So, if you compare the best results of 3D printers, CNC-made parts can head straight to any destination. Those from 3D printing will need different processes to complete the tasks.

Overall, CNC machining becomes more efficient than 3D printing. The latter lacks precision for some complex applications.

You can use a selective laser melting mechanism that prints 3D outputs when using metal. But, the accuracy isn't like CNC machines.

CNC machining is unbeatable when it comes to both accuracy and speed. That's because its tolerance and accuracy are unique. You can expect the accuracy value of CNC machining to be around +-0.01mm to +-0.05mm. Well, it also depends on the geometry.

On the other hand, the surface quality achieved in 3D printing may not be as good as CNC. Note that 3D printing offers an accuracy of approximately +-0.1mm. Besides, the manufacturing speed in 3D printing will also vary depending on the required accuracy.

5) Impact on the Environment

CNC machining involves the cutting away of material from a standard block. Of course, it will be messy in the end. You need to clean the pieces of stuff after the manufacturing process.

All these and disposing of the mess is not part of the 3D manufacturing process. Additive manufacturing will form an object without producing waste.

Of course, every manufacturer wants to minimize material waste during the production process. If not reduced, we should at least reuse the waste material.

Several operations in CNC can result in swarf. It includes milling, drilling, turning, etc. Well, it is possible to reuse metal and plastic scraps in a suitable production process. However, we cannot use particular waste like wood scraps.

But, you need to feed the material into your machine. There is minimal to no mess apart from supports if you will use any.

In comparison, 3D printing is more ethical as there is less waste.

CNC or 3D Printing - Which Is More Beneficial?

We hope you now understand the vital differences between 3D printing and CNC. So, let's figure out which method can bring in more benefits for you.

1) Strength

In most cases, manufacturers prefer CNC machining for working on metals. Thus, CNC machines mostly use monolithic materials having excellent thermal and mechanical properties.

3D printing can process a wide range of materials, especially liquid materials. Thus, you cannot expect the materials to have good physical properties. Besides, they have fewer mechanical properties compared to the materials used in CNC machining.

2) Waste

CNC machines are standard for making precise, durable, and more heat-resistant parts. These machines are available in almost all industries.

The industries range from small businesses to large production factories. There is a wide range of applications, and the waste is considerable. Whether in casting, metal molding, or jewelry.

Unlike CNC machining, 3D printing uses the exact amount of material you need to create an object. Here the waste is minimal. But don't forget the material you might need for support structures.

But as mentioned above, we can reuse metal and plastic scraps resulting from CNC operation. You can recycle swarf in many ways.

Remember, CNC machining scrap holds value most of the time. You can sell metal scrap to a recycler. You can also reuse the waste material as long as it is not wood scrap. Be it slivers or tiny flecks of metal! You can reuse it anytime.

3) Variety of Applications

It is best known for precise, heat-resistant, and durable parts. CNC machining is widespread in most, if not all, industries. The size of the business isn't an issue.

Yet, 3D printing also captures the vision of most people. Some fields where this method applies are healthcare, aerospace, and engineering. Others are bio-printing, food printing, jewelry, and building and construction.

4) 3D Models and Software

Preparing software for CNC machining processes is somewhat more complicated than 3D printing. It is essential to create tool paths using computer-aided manufacturing software.

A specialist needs to specify the location. Also, they check the dimensions of stock material and cutter characteristics. Other things to put in place are the spindle and speeds of axes, among others.

On the other hand, 3D printers are more accessible. You need special software known as a slicer for transferring digital models in the G-code. It is what controls the 3D manufacturing process.

The slicing method is more straightforward than having to pre-program CNC machines.

5) Variety of Tools

You can use a couple of tools in the same CNC machine. It broadens the capabilities and makes this process more versatile. We attribute everything to CNC technology.

Some machines can automatically change tools to your current task. The manufacturing process will not have extended breaks.

For 3D printing, there are limited tools available. Most of the time, this can be problematic. But, when you use this additive method of manufacturing, others aren't necessary. 3D printing boasts incredible diversity.

6) Speed

The complexity of the design plays a notable role here. It and your choice of material will determine the manufacturing speed if you are using CNC machines. It could be terrific and, in most cases, unrivaled.

But, remember that pre-programming some processes can take more time, especially if you are handling trickier projects.

The turn-around time for this manufacturing can take 3 to 4 days. For 3D printing, this could be 1 or 2 days.

In some cases, 3D printing can be slower and isn't the best option for any serial production. The reason it is termed rapid prototyping is the printers don't need longer pre-programing. It takes a short time to run them.

What it needs is loading the material and slicing files. It is something you can do in a few minutes and then send it to the printer.

Additive manufacturing keeps improving day by day. Today's machines are working faster than older designs.

7) Post-processing

Sometimes, details you make with CNC machines need post-processing like sanding, sandblasting, plating, brushing, and grinding.

Sanding Process

Sandblasting Process

Brushing Process

Grinding Process

Also, you can sand and finish the parts on the same CNC machine. The results here are as great as the cast.

In 3D printing, the products need post-processing. Suppose you have been temperature processing any metal parts with internal stress. Then, you can use some of them right away after printing.

FAQs on CNC Vs. 3D Printing

1) What Are the Notable Differences Between 3D Printing and CNC Machining?

Most 3D printing users say that it is easier to use than CNC machines. Once you prepare the file, all you need is to choose the orientation parts and filling.

The printer might need support but not always necessary. Once you start printing, there is no need for supervision. Leave the printer until the printing process is complete. The technology will influence the post-processing needs.

But, CNC machining needs a specialist to assess the various tools. It works on unique manufacturing principles. As a subtractive process, it begins with a chunk of material. It uses programming controls.

You can choose from 3-axis, 4-axis, and 5-axis machines. These are called computer numerical controls. The CNS controls the movements of these machining tools in three dimensions. The machines remove material until the machining process is complete. You will remain with your final product.

Among all these, 5-axis machine can help you create complex parts. Besides, you also need to perform less rotation operations in 5-axis machines. It all saves the manpower and also improve the production speed and accuracy.

2) Should I Get a CNC Machine or 3D Printer for My Business?

CNC machining is older than 3D printing. But, most people are embracing the two in equal measures. Remember, you might have to use them hand-in-hand in some situations.

Each presents its significant benefits over most traditional methods like injection molding. It will be helpful to assess your needs before choosing what works best for you.

What you buy will depend on your needs. 3D printers are versatile. But, certain factors can get in the way of your decision.

If you are yet to decide, 3D printers are excellent options. If you are skilled enough, CNC machines will work for you. More advanced models have minimal noise and waste. But, you will need a workshop to store these machines since they are bulky.

Some 3D printers are slower but can be cheaper for low-volume productions. You need basic training to operate them. Emissions are lower, and you can have them in the office space.

Consider all the aspects before making a decision. It will be better if you can get other competitive advantages of the two methods.

3) Can Metal 3D Printing Replace the Usual CNC Machining?

3D printing and CNC machining use similar core technologies. Advancement in one will push improvements in the other.

If it is about the entire manufacturing process of metallic parts, it is different. CNC machining and metal 3D printing can't replace each other.

Metal 3D printing is improving and might replace some processes. But, we will still need CNC machining.

4) Is CNC Machining Cheaper Than 3D Printing?

On most average instances, 3D printing is more affordable than CNC machining. But, costs will depend on the number of parts you need and how fast you need them.

Speed is a vital element when it comes to choosing between 3D printing and CNC machining. Of course, CNC can give you a faster production speed for making a particular product in mass quantity. We only need to set up an assembly line of machines that can create each part.

On the other hand, 3D printing involves making the whole product from start to finish. Thus, the 3D printing process may not be ideal for large-scale productions.

For vast quantities of high double digits, CNC machining will be the best option. 3D printing is appropriate for lower volumes. If you need your parts of prototypes faster, 3D printing is the best pet.

More factors will make cost comparisons quite tricky. One is the varying costs of material. Cheap materials such as ABS will not cost the same as those about $500 per kilogram. Moreover, changing and repairing machinery like CNC heads will influence the overall costs.

Final Thoughts!

To some extent, both CNC machining and 3D printing may overlap. Most often, in performance and capabilities. But, each has the benefits that make it suitable for special applications.

CNC machining is excellent for tasks that need high precision. Also, it creates complex products from ready materials. Most people prefer this for cost efficiency and accuracy.

Characteristics of the new 3D printing make the process perfect for creating prototypes. Others that work for it are custom-design products and visual justification.

Everything is rounded up together; the world is an open field. It is packed with more room for CNC machines and 3D printers. So, choose the right technology for your next production.