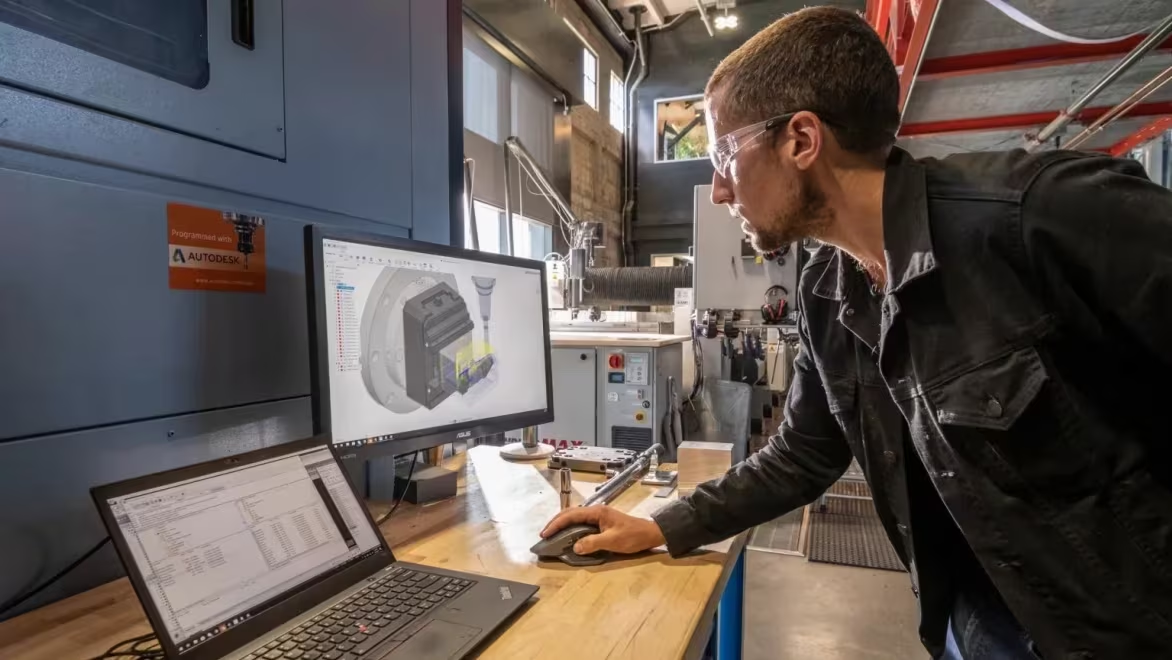

In the industrial sector, notably in the field of computer numerical control (CNC) machining, computer-aided manufacturing (CAM) and computer-aided design (CAD) software have become indispensable tools. By enabling designers and engineers to build and simulate concepts in an artificial world before manufacturing them in the real world, CAM/CAD software can enable CNC machines to operate efficiently and accurately.

For CNC machining, there are various renowned CAM/CAD software available, each with perks and drawbacks. Designers and engineers may develop 3D models using these software tools, and they can also produce toolpaths that CNC machines can use to efficiently make complicated and accurate parts.

So, which CAD/CAM software is suitable for CNC machines? You can choose the ideal tool for your production needs by reading this article which includes details on their features and strength. So, Let’s begin.

1. What Does CAD/CAM Software Do?

In the fields of engineering and manufacturing, CAD/CAM software is a type of computer program used to design and produce items. Computer-Aided Manufacturing is often known as CAM, while CAD stands for computer-aided design.

2D or 3D models of goods or parts are produced using CAD software. Before a product is ever created, it allows engineers and designers to visualize and alter its design. Sketches, wireframes, and intricate models of individual components or assemblies can be produced as part of this process.

On the other side, CAM software is utilized to regulate and automate the production process. The physical product is produced using toolpaths and instructions produced by CNC (Computer Numerical Control) machines, lathes, and milling machines using the digital design developed in CAD software.

Collectively, CAD/CAM software offers a potent toolkit for product development and production, empowering engineers and designers to efficiently and accurately build complex items. It is utilized in a variety of sectors, including consumer goods, electronics, and the automobile and aerospace industries.

2. Premium CAM/CAD Software

There are plenty of advanced CAD/CAM software solutions on the market, each with special capabilities and perks. Professional engineers and machinists often utilize premium CAM (Computer-Aided Manufacturing) software since it offers cutting-edge functionality for manufacturing. Thus, Let’s explore some details on popular premium CAM software:

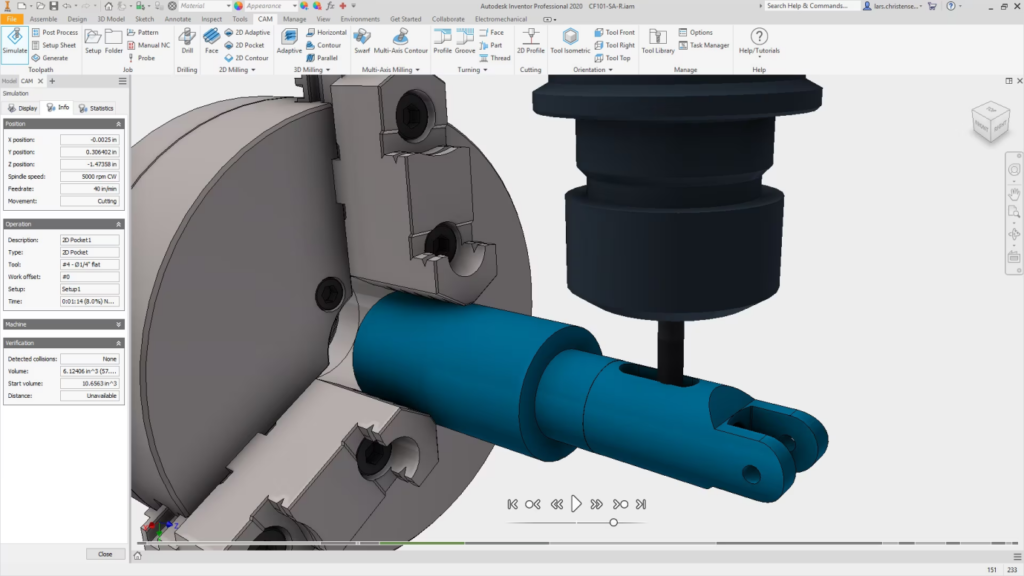

1. Autodesk CAM

Fusion 360, HSMWorks, and PowerMill are among the CAM software alternative solutions provided by Autodesk. Advanced functionality like 5-axis machining and toolpath optimization are offered by these software alternatives.

In addition to toolpath creation for milling, turning, and wire EDM, it also contains a variety of solutions for CNC programming, simulation, and verification. Autodesk CAM software has a number of important features, such as:

Integrated CAD/CAM: Autodesk's 3D design software and CAM software are both available together, enabling customers to transfer design data easily to the CAM program for fabrication.

Automatic toolpath generation: The software is capable of producing toolpaths automatically for a variety of machining operations, including turning, wire EDM, 3D milling, and 2D milling.

Simulation and verification: Tools for simulation and verification are included in the software, enabling users to test toolpaths before sending them to the machine, reducing the chance of errors and loss.

Post-processing: The CAM software from Autodesk has post-processing features that enable the toolpaths to be transformed into NC code that can be used to control CNC machines.

Collaboration over the cloud: Some software versions enable users to communicate and exchange information in real-time using platforms based on the cloud.

Some of its drawbacks include limited compatibility, high cost, and lack of customization.

2. Mastercam

Photo by NED Directory Diegest

Machinists, engineers, and designers use Mastercam, a computer-aided manufacturing (CAM) program, to program and manage CNC machines. The premium version of Mastercam software, also known as Mastercam X9, offers sophisticated features and tools for 2D and 3D modeling, toolpath development, and machining simulation.

Mastercam provides a variety of features and tools for 2D and 3D modeling, in addition to powerful surface modeling, solid modeling, and multi-axis machining. Numerous toolpath techniques are also included for drilling, tapping, finishing, and other operations.

The program offers simulation capabilities to visualize the machining process and spot any potential faults or collisions. It also supports a broad variety of file formats. Among Mastercam X9'a most important attributes are:

Dynamic Motion Technology: This feature analyses the cutting circumstances and modifies the toolpath as necessary to optimize toolpath motion and shorten cycle times.

Multi-axis machining: The program allows for up to 5-axis machining, which enables designers to produce complex parts with minimum setups and greater precision.

Advanced toolpath creation: Mastercam X9 offers a variety of advanced toolpath generation techniques, including 3D contouring, rest milling, and surface high-speed machining.

Machining simulation: Software that simulates the machining process enables users to find and correct potential mistakes before going through the real machining process.

CAD integration: To enable easy design data transmission, Mastercam X9 interconnects with well-known CAD programs like SolidWorks and AutoCAD.

Its limitations include limited 3D modeling capability and lack of cloud integration.

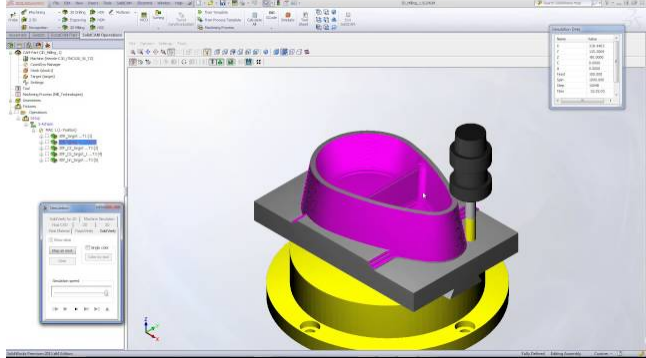

3. SolidCAM

SolidCAM is a robust and all-inclusive computer-aided manufacturing (CAM) program used in the manufacturing and engineering sectors. In order to design, program, and simulate CNC machines and create high-precision parts and components, it offers a variety of tools and functionalities.

SolidCAM's premium version frequently comes with cutting-edge capabilities including simultaneous milling, multi-tasking machining, and 5-axis machining. Such characteristics enable users to accurately and efficiently build complicated components and parts.

However, depending on the provider and the licensing choices, the particular features and cost of the premium version of SolidCAM may change.

Premium CAD Software

Premium CAD (Computer-Aided Design) software offers innovative features for creating intricate 2D and 3D models. Notable examples of high-end CAD software include:

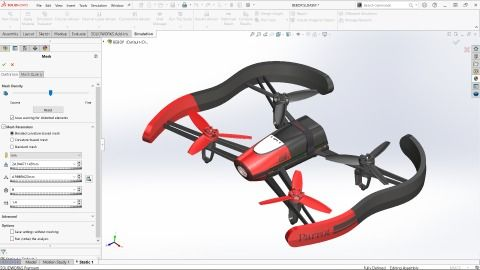

4. SolidWorks

A popular CAD program called SolidWorks is used for 3D modeling, simulation, and product design. For the purpose of developing and engineering complicated items, it provides a variety of features and tools.

The commercial program SolidWorks offers a number of modifications with varied levels of features and functionalities. The premium version of the software provides the most extensive set of capabilities and tools for developing intricate items.

Advanced simulation expertise, photorealistic rendering, advanced CAD tools for sheet metal and plumbing, and a variety of advanced design tools for designing complicated components and assemblies are some of the features offered by SolidWorks Premium.

But, It has some limited simulation capabilities, compatibility issues, and a lack of flexibility.

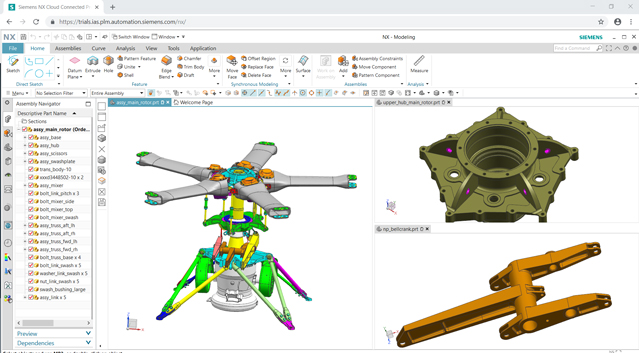

5. Siemens NX

Computer-aided design (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE) are all capable of being done with the help of Siemens NX, a potent software platform. In fields like automotive, aerospace, and machine design, it is extensively used.

Siemens NX is a broad software package that provides a number of high-end functions for product design, engineering, and manufacturing. The following are some of Siemens NX's main premium features:

Advanced Modelling: Siemens NX has powerful modeling features that make it simple for users to develop intricate patterns and geometries. It has capabilities including direct modeling, reverse engineering, and freeform modeling.

Advanced simulation and analysis: These features in Siemens NX allow users to forecast how their designs will function under various real-world scenarios. Finite element analysis, computational fluid dynamics, and thermal analysis are just a few of the simulation techniques it provides.

Additive Manufacturing: Design for additive manufacturing, 3D printing, and post-processing are all included in the entire toolkit for additive manufacturing provided by Siemens NX.

Surface Design: Siemens NX has powerful surface design features that make it simple for users to easily generate complicated surface geometries.

CAM: Siemens NX comes equipped with computer-aided manufacturing (CAM) features that let users create toolpaths for manufacturing operations including milling, turning, and drilling.

But, It has some issues that include heavy system requirements and limited support.

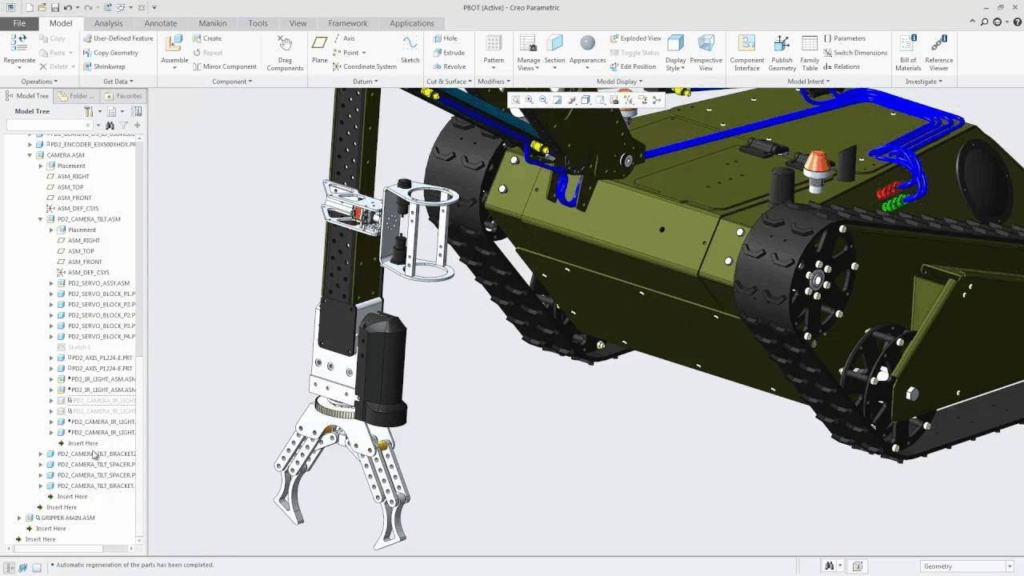

6. PTC Creo

It is a group of computer-aided design (CAD) software programs that let users create, evaluate, and alter designs for items and parts. In fields including aerospace, automotive, and industrial manufacturing, it is frequently employed.

PTC Creo's premium version offers extra features and functionalities not found in the basic version, including sophisticated simulation and analysis tools, reverse engineering capability, and collaborative design tools. Access to extra modules or extensions, like specialized modules for sheet metal design or mold design, may also be included. PTC Creo has a number of important features, including:

Advanced 3D modeling: Using a number of tools and methods, such as parametric design, direct modeling, and freeform surfacing, PTC Creo enables users to generate complex 3D models of products and parts.

Advanced simulation and analysis: These capabilities are included in the software to allow developers to verify and test designs for products. These tools include structural, thermal, and fluid simulations.

Reverse engineering: PTC Creo enables users to alter or enhance current designs by generating 3D CAD models from practical physical components or finished goods.

Sheet metal design: Specialized capabilities for creating and changing sheet metal parts and products are offered inside the software, providing the capability to make flat templates and assess the viability of manufacturing.

But, It has Limited support for non-engineering disciplines and complexity issues.

4. Free CAD/CAM Software

Here are some of the available free CAD/CAM software options:

● FreeCAD:

It is a parametric 3D modeling program that is open-source and free. Users can produce 2D drawings, 3D assemblies, and models. It supports numerous file formats and has a sizable user base.

● Fusion 360:

This program offers a free license for private, non-commercial usage, despite the fact that it is not entirely free. It is a 3D modeling, simulation, and CAM CAD/CAM program that is cloud-based. Autodesk also offers a free trial of it.

● PyCAM:

PyCAM is a 3-axis and 4-axis CNC milling machine supporting an open-source CAM program. It supports a number of file formats and has an intuitive user interface.

● OpenSCAD:

OpenSCAD is a free software program that enables the script-based creation of solid 3D CAD objects. It accepts file types like STL and DXF and is very helpful for developing mechanical parts.

● CAMotics

CAMotics is an open-source, simulation-based CAM program that enables users to test and simulate their CNC programs before executing them on a real machine. Both milling and turning operations can be performed using it, and it provides support for a number of CNC machines.

● OpenCAMLib:

You can create unique CAM apps with this open-source CAM library. It offers a range of functionality, such as 2D and 3D milling, turning, and drilling, and supports a number of CNC machines.

5. How to Choose the Best CAD/CAM Software?

The finest CAD/CAM software to use will rely on a number of things, including the requirements of your company, your budget, and the sector of business you are in. The following elements should be taken into account while choosing the finest CAD/CAM software for your CNC machine:

Industry-specific features: Some CAD/CAM programs are made expressly for the automotive, aerospace, or architectural industries. If you operate in a specific industry, take into account software that has the functionalities you require.

Compatibility: Check the software's compatibility with your hardware, operating system, and any other software applications you could use at work.

Customization: Software that can be tailored to your unique demands should be used. You can improve your workflow and raise your productivity. It also should be easy to use.

Cost: Take into account the price of the product as well as any supplementary costs, such as support or training. In order to get the best value for your money, decide which characteristics are most important to you.

Support and training: Pick software that includes online tutorials, documentation, and customer service in addition to thorough support and training.

Reviews and remarks: Examine the reviews and comments left by other software users. This can offer insightful information about the software's features and drawbacks.

You can choose the best CAD/CAM software for your company by taking these aspects into account and investigating the available choices.

The Bottom Line:

There are many widely recognized CAM/CAD programs for CNC machining, each having benefits as well as drawbacks. We shared a wide variety of premium and free CAM/CAD software for CNC machines. With the use of these above-mentioned software tools, designers and engineers can create 3D models as well as toolpaths that CNC machines may use to quickly build intricate and precise parts.

This blog was informative for you? Do you have anything to share about this blog? Just let us know by commenting below.