Packaging lines face relentless pressure to increase throughput while maintaining reliability. Equipment failures cause costly production delays, rejected products, and missed deadlines—problems that ripple throughout the supply chain.

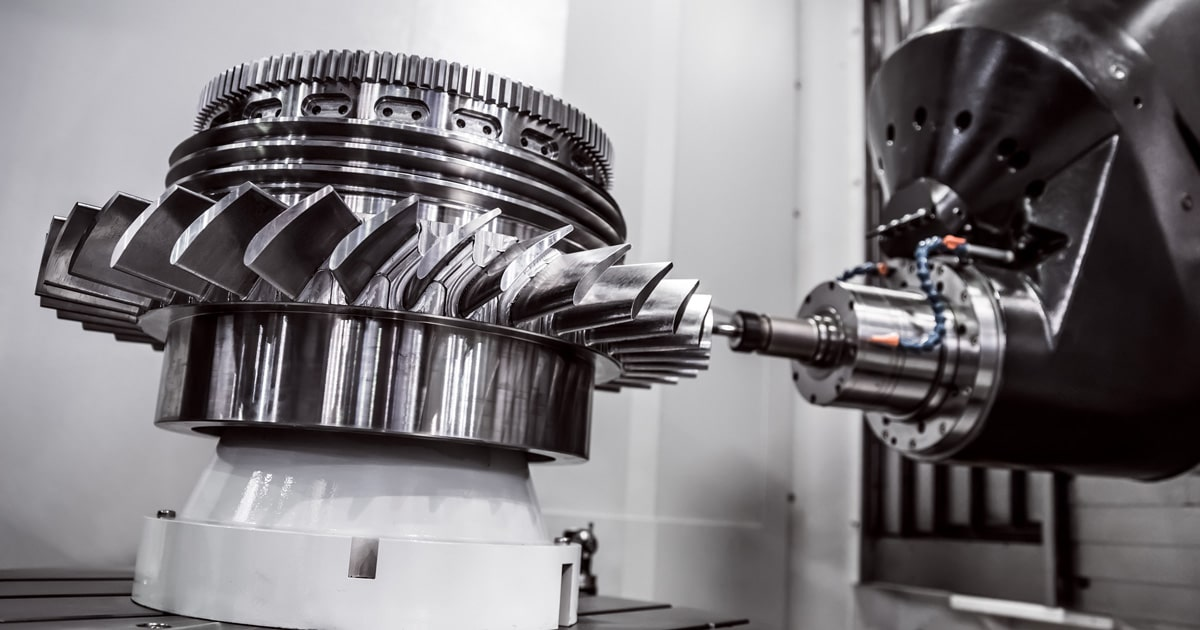

CNC machining addresses these challenges by creating components with exceptional precision and consistency. Modern packaging equipment relies on precisely machined parts that maintain tolerances within microns, ensuring smooth operation at high speeds while reducing wear patterns that lead to system failures.

CNC machining for packaging equipment

In our factory, we've witnessed the transformation that precision-machined components bring to packaging systems. From food processing lines to pharmaceutical packaging, the demands for speed, reliability, and sanitary design have never been higher. Let me share what we've learned about maximizing packaging equipment performance through strategic CNC machining approaches.

Which CNC Materials Ensure Optimal Performance in High-Speed Packaging Lines?

Production managers struggle with component failures that cause expensive downtime. Traditional materials often wear prematurely under the stress of continuous high-speed operation, leading to costly replacements and production losses.

The ideal materials for high-speed packaging lines combine wear resistance, appropriate hardness, and dimensional stability. Stainless steel grades like 316L excel in food packaging due to corrosion resistance, while aluminum 6061-T6 provides lightweight strength for moving components, and engineering plastics like PEEK offer self-lubricating properties for parts requiring low friction.

High-performance materials for packaging equipment

Material selection represents one of the most critical decisions when designing packaging equipment components. I've seen firsthand how the right material choice can extend component life by 300% or more in high-cycle applications. For example, when we upgraded a client's cam followers from standard steel to hardened 440C stainless, their maintenance intervals extended from monthly to quarterly.

When selecting materials, we consider not just the mechanical properties but also the operating environment. Food and pharmaceutical packaging demands materials that resist bacterial growth and withstand aggressive cleaning chemicals. This is why we often recommend specific stainless steel grades with electropolished finishes for food contact components.

Material Comparison for High-Speed Packaging Applications

| Material | Advantages | Best Applications | Typical Lifespan |

|---|---|---|---|

| 316L Stainless | Excellent corrosion resistance, FDA compliant | Food contact surfaces, wash-down environments | 5+ years |

| 7075 Aluminum | High strength-to-weight ratio | Moving assemblies, pick-and-place components | 3-5 years |

| PEEK | Excellent corrosion resistance, FDA-compliant | Bearing surfaces, guide components | 4+ years |

| Titanium | Exceptional strength, lightweight | High-stress components, corrosive environments | 7+ years |

How Can Precision Machining Reduce Downtime in Packaging Operations?

Maintenance teams constantly battle unplanned downtime caused by premature component wear, misalignment, and catastrophic failures. Every minute of stopped production directly impacts profitability and delivery schedules.

Precision CNC machining creates components with exacting tolerances that ensure proper fit, reduce vibration, and minimize wear patterns. With tolerances maintained within ±0.005mm, components like guide rails, bearing housings, and drive mechanisms operate with minimal friction and stress, dramatically extending service intervals.

Precision components reducing downtime

The relationship between machining precision and system reliability cannot be overstated. In our experience manufacturing packaging equipment components, we've found that tolerance stacking represents one of the most overlooked aspects of system design. When multiple components in an assembly each have their own tolerance range, these variations can compound, leading to misalignment and premature failures.

We implemented a comprehensive approach for a beverage packaging client who was experiencing frequent failures in their capping mechanism. Through detailed analysis, we identified that the tolerance stacking in five connected components was creating misalignment under load. By redesigning with tighter tolerances and matching components during assembly, we reduced their downtime by 78% and extended maintenance intervals from weekly to monthly.

Critical Tolerance Requirements for Packaging Components

| Component Type | Critical Tolerance Range | Impact on Performance |

|---|---|---|

| Cam mechanisms | ±0.01mm | Ensures smooth motion profiles, prevents jamming |

| Bearing seats | ±0.005mm | Extends bearing life, reduces vibration |

| Sealing surfaces | ±0.02mm | Prevents leakage in liquid filling systems |

| Drive components | ±0.015mm | Reduces backlash, improves positioning accuracy |

What Makes CNC-Machined Components Superior for Food Packaging Equipment?

Food manufacturers face strict regulatory requirements and contamination risks. Traditional fabrication methods often create hard-to-clean surfaces with microscopic crevices where bacteria can hide, potentially leading to product recalls and brand damage.

CNC machining creates components with superior surface finishes and precise geometries that eliminate hidden crevices and collection points. The process allows for creating sanitary designs with rounded internal corners, smooth transitions, and polished surfaces that facilitate cleaning and prevent product contamination.

Sanitary design components for food packaging

Food safety considerations drive much of our approach when designing components for food packaging equipment. I recall working with a dairy processing client who was experiencing product contamination issues. Their existing filling system had components with traditional manufacturing methods that created microscopic cracks and crevices where cleaning chemicals couldn't effectively reach.

By redesigning these components using our 5-axis CNC capabilities, we created parts with continuous surfaces, eliminating the 90-degree internal corners that were harboring bacteria. The electropolished finish further reduced surface roughness to under 0.8μm Ra, creating a surface that resisted bacterial adhesion. The result was a system that not only passed their rigorous swab testing but also reduced their cleaning cycle time by 35%.

Sanitary Design Principles in CNC Machining

| Design Principle | Implementation Method | Regulatory Compliance |

|---|---|---|

| Eliminate crevices | Radius all internal corners (min 3mm) | FDA 21 CFR 110.40 |

| Minimize horizontal surfaces | Design with sloped surfaces (min 3° angle) | 3-A Sanitary Standards |

| Create cleanable surfaces | Electropolish to <0.8μm Ra finish | EHEDG guidelines |

| Prevent contamination traps | Eliminate blind holes and threads in product zones | ISO 14159 |

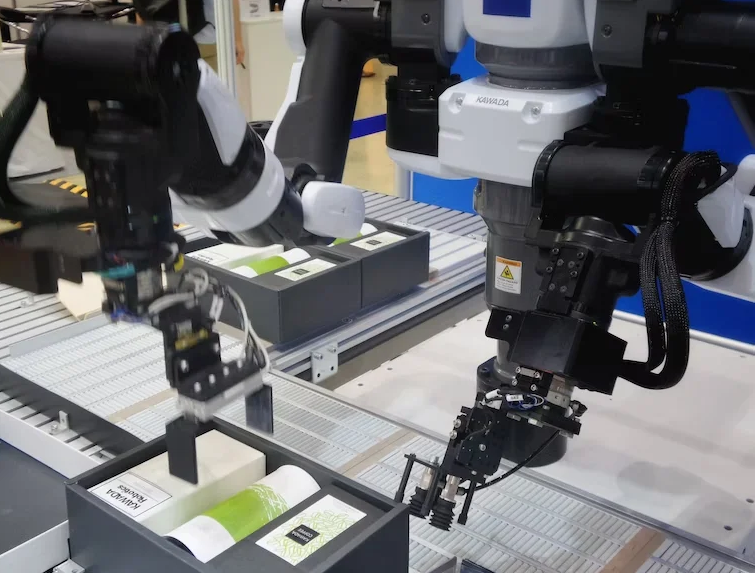

Which Assembly Techniques Maximize Packaging Machine Reliability?

Engineers struggle with traditional joining methods that create stress points, misalignments, and eventual failures. Welding can introduce heat distortion, while bolted assemblies may loosen under vibration, both compromising long-term reliability.

The optimal approach combines precision CNC machining with strategic assembly techniques. Interference fits, keyed connections, and specialized fastening systems maintain component alignment even under dynamic loads. These methods eliminate relative movement between parts, preventing wear and extending service life.

Advanced assembly techniques for reliability

Assembly methodology represents the final critical step in creating reliable packaging systems. We've developed specialized techniques that preserve the precision created during the machining process. For instance, when assembling high-speed cam systems, we use controlled-temperature press fits rather than conventional bolted connections to maintain perfect alignment while eliminating fastener loosening concerns.

A pharmaceutical packaging client approached us after experiencing repeated failures in their pill-counting system. The existing design relied on conventional bolted connections that would gradually loosen under vibration, creating misalignment and eventual failure. Our solution involved redesigning the assembly with tapered locating features and specialized torque sequences. We also implemented a heating process for assembly that created interference fits without mechanical stress. The revised system has now operated for over 18 months without a single alignment-related failure—a dramatic improvement over their previous 6-8 week failure cycle.

Advanced Assembly Techniques for Packaging Equipment

| Assembly Method | Best Applications | Maintenance Advantages |

|---|---|---|

| Precision dowel alignment | Component positioning in critical assemblies | Ensures consistent reassembly during maintenance |

| Temperature-differential fitting | Bearing assemblies, precision shafts | Eliminates mechanical stress during assembly |

| Specialized fastening sequences | Vibration-prone components | Maintains proper preload, prevents loosening |

| Surface treatment interfaces | High-load transfer joints | Increases friction coefficient, prevents slippage |

Conclusion

Precision CNC machining transforms packaging equipment performance through optimized materials, tight tolerances, sanitary designs, and advanced assembly techniques. Our integrated approach delivers components that maximize uptime, ensure product safety, and provide lasting reliability in demanding production environments.