Are you struggling with complex part geometries or precision requirements? Side milling might be the solution you've been overlooking, despite being one of the most versatile techniques in our CNC arsenal.

Side milling is a fundamental machining process where the cutting tool removes material along its peripheral edge. It excels at creating slots, pockets, and contours with high accuracy, making it indispensable for parts requiring precise side features or complex profiles.

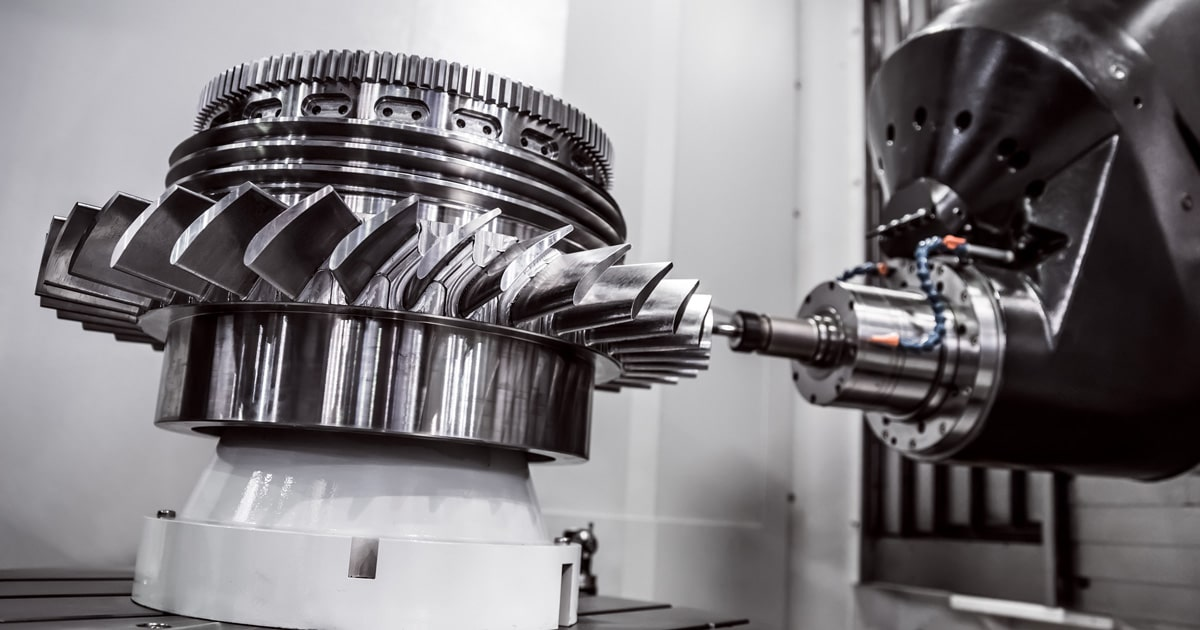

Side milling operation in progress

In our decades of experience providing machining services, I've seen side milling evolve from a basic operation to an essential technique that drives precision manufacturing. Let me walk you through why this technique matters so much and how it can transform your production capabilities.

How Does Side Milling Differ from Other Milling Techniques?

Feeling confused about when to use side milling versus face milling or other techniques? This distinction can mean the difference between a perfect part and a costly rework.

Side milling utilizes the peripheral cutting edges of an end mill to remove material along the sides of a workpiece, creating vertical surfaces. In contrast, face milling uses the bottom of the tool to create horizontal surfaces, while profile milling follows contours to create complex shapes.

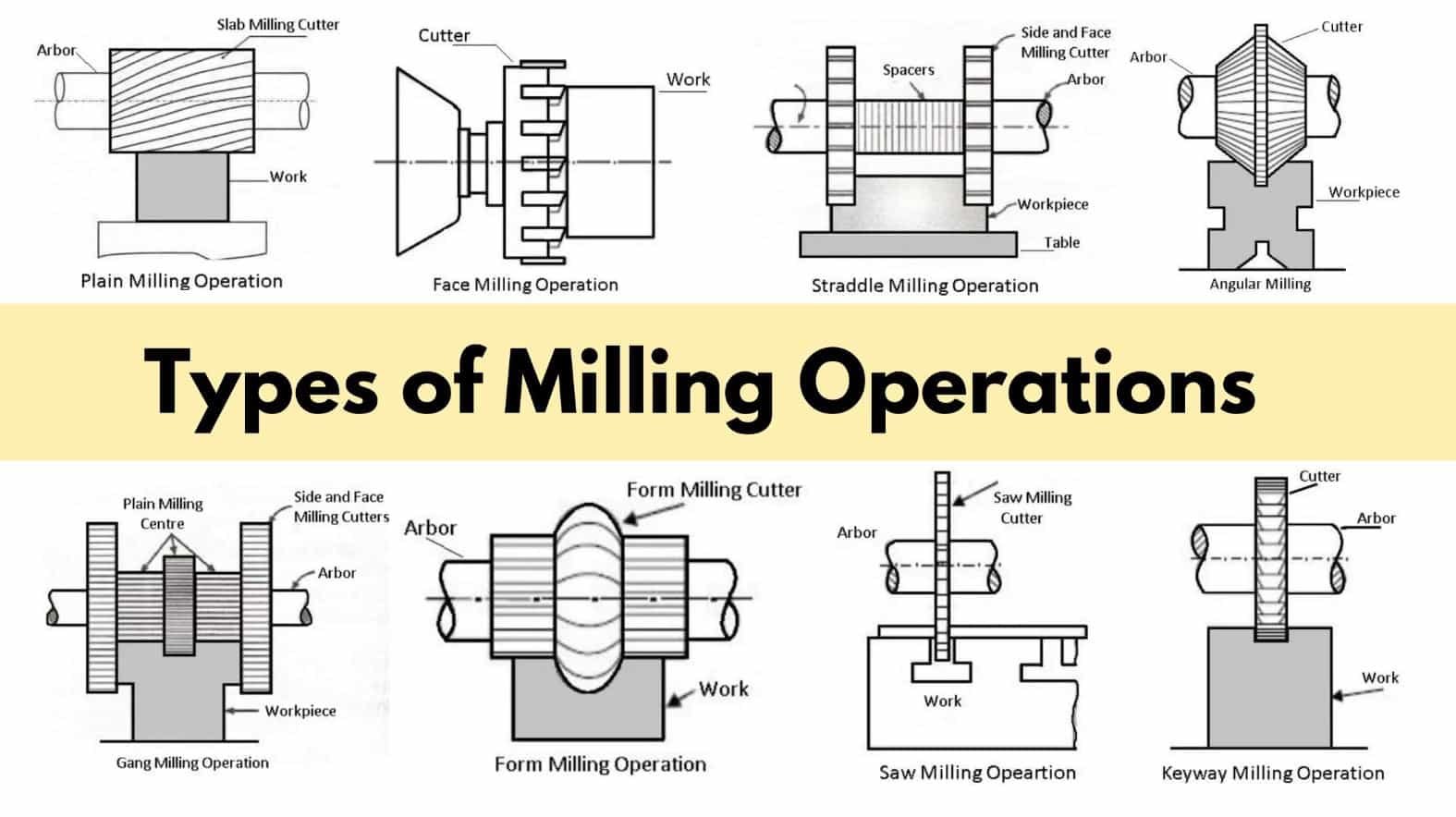

Side milling vs face milling comparison

Side milling stands apart from other machining methods due to its unique approach to material removal. In our Kunshan facility, we regularly employ different milling strategies depending on the requirements of each project. Side milling primarily engages the peripheral edges of the cutting tool, creating vertical walls and features, while face milling utilizes the bottom cutting edges to generate flat, horizontal surfaces.

The key differences lie in tool engagement and cutting forces. During side milling, cutting forces are directed perpendicular to the tool axis, which can sometimes lead to deflection challenges. This contrasts with face milling, where forces are more aligned with the tool's axis, generally providing more stability.

Side milling also differs in its approach to chip evacuation. The chips move outward from the cutting zone, making it excellent for deeper cuts where chip removal is critical. This characteristic makes it particularly valuable for creating features like keyways, slots, and pockets.

| Milling Type | Primary Cutting Edge | Typical Applications | Tool Deflection Risk |

|---|---|---|---|

| Side Milling | Peripheral edges | Slots, pockets, vertical walls | Higher |

| Face Milling | Bottom edges | Flat surfaces, large areas | Lower |

| Profile Milling | Combination | Complex contours, 3D shapes | Moderate |

What Are the Common Types of Side Milling Operations?

Wondering which side milling approach will deliver the best results for your specific component? The right technique can dramatically impact your part's quality and production time.

Side milling encompasses several specialized operations, including conventional milling (cutting against feed), climb milling (cutting with feed), slot milling, and peripheral milling - each offering distinct advantages for specific geometries and materials.

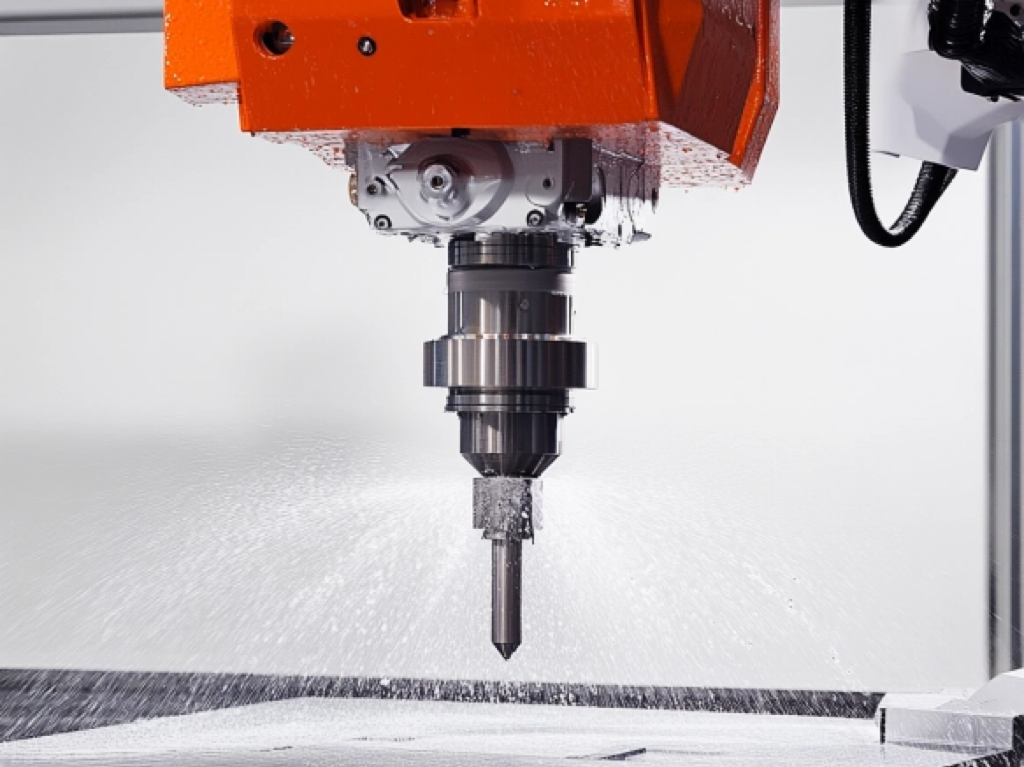

Common side milling operations

In our machining center, we perform several variations of side milling operations to address different manufacturing challenges. Understanding these variations is crucial for selecting the optimal approach for each unique part requirement.

Conventional milling (up-milling) is where the cutter rotates against the direction of the feed. This technique starts with a thin chip that gets progressively thicker, resulting in less initial impact on the tool but potentially causing the cutter to ride up on the workpiece. We typically use this method when working with older machines that have backlash issues or when dealing with materials with hard outer surfaces.

Climb milling (down-milling), by contrast, has the cutter rotating in the same direction as the feed. The chip starts thick and gets thinner throughout the cut, resulting in better surface finish and reduced tool wear. Our operators prefer this method for most applications as it produces cleaner edges and better dimensional accuracy.

Slot milling is another common side milling operation where the full diameter of the tool is engaged to create channels or slots. This technique requires careful consideration of cutting parameters due to the high engagement and restricted chip evacuation.

Peripheral milling involves machining the outer edges of a workpiece to create specific profiles or contours. We often employ this technique for complex geometrical features like curved surfaces or irregular shapes.

| Operation Type | Chip Formation | Surface Finish | Tool Wear | Typical Applications |

|---|---|---|---|---|

| Conventional Milling | Thin to thick | Good | Moderate | Hard-surfaced materials, older machines |

| Climb Milling | Thick to thin | Excellent | Lower | Most precision applications |

| Slot Milling | Full engagement | Variable | Higher | Channels, keyways, grooves |

| Peripheral Milling | Variable | Very good | Moderate | Complex profiles, contours |

What Are the Main Advantages and Limitations of CNC Side Milling?

Unsure if side milling is the right approach for your project? Understanding its strengths and weaknesses can help you make better manufacturing decisions and avoid costly mistakes.

Side milling offers exceptional versatility for creating vertical walls, complex profiles, and intricate features with high precision. However, it can face challenges with tool deflection, vibration in deep cuts, and increased tool wear compared to some other methods.

Advantages and limitations of side milling

After thousands of machining projects, I've developed a deep appreciation for both the capabilities and constraints of side milling operations. This understanding helps us leverage the technique's strengths while mitigating its limitations.

The primary advantage of side milling is its versatility. The process excels at creating complex geometries that would be difficult or impossible with other methods. In our vacuum chamber projects, for instance, side milling allows us to create precise internal features with tight tolerances. The technique also provides excellent surface finish capabilities, particularly when using climb milling with optimized parameters.

Another significant benefit is the ability to machine deep features without the need for specialized deep-hole drilling equipment. Side milling can effectively create pockets, channels, and slots with depth-to-width ratios that would challenge other methods. Additionally, the process offers good chip evacuation when properly executed, which is crucial for maintaining part quality and tool life.

However, side milling does come with limitations. Tool deflection remains a persistent challenge, especially when machining deep features or using slender tools. This deflection can lead to dimensional inaccuracies and poor surface finish. In our experience machining automotive components, we've found that careful tool selection and progressive depth passes are essential to mitigate this issue.

Vibration and chatter can also pose problems, particularly in unsupported or thin-walled sections. These issues can compromise surface quality and accelerate tool wear. Furthermore, side milling typically subjects cutting tools to more stress than face milling operations, potentially reducing tool life if not managed properly.

| Advantages | Limitations |

|---|---|

| Excellent for complex geometries | Susceptible to tool deflection |

| Superior surface finish capability | Potential for vibration/chatter |

| Effective for deep features | Higher tool wear in certain conditions |

| Good chip evacuation | Reduced material removal rate vs. face milling |

| Precise vertical wall creation | Requires careful parameter selection |

What Factors Affect the Quality of Side Milling?

Frustrated with inconsistent side milling results? The root cause might be hiding in one of these critical factors that many machinists overlook until problems arise.

Quality side milling depends on multiple interrelated factors, including tool selection, cutting parameters, machine rigidity, workpiece fixturing, and coolant application. Optimizing these elements ensures dimensional accuracy, surface finish, and tool longevity.

Factors influencing side milling quality

Through years of machining experience across various industries, I've identified several critical factors that significantly impact side milling quality. Understanding these factors has allowed us to consistently achieve precise results even with challenging materials and geometries.

Tool selection stands as perhaps the most influential factor. The number of flutes, helix angle, coating type, and tool material all play crucial roles in determining cutting performance. For our aerospace components, we typically select carbide end mills with appropriate coatings tailored to the specific material being machined. The tool's rigidity-to-reach ratio is particularly important in side milling to minimize deflection.

Cutting parameters—including speed, feed, and depth of cut—must be carefully balanced. Excessive cutting speed can lead to premature tool wear and thermal damage, while insufficient speed reduces productivity. Similarly, feed rate affects chip load and cutting forces, directly impacting surface quality and tool life. In our Kunshan facility, we maintain an extensive database of optimized parameters for different material-tool combinations based on past project results.

Machine rigidity significantly affects the outcome of side milling operations. Even with perfect tools and parameters, an insufficiently rigid machine will produce poor results due to vibration and deflection. We've invested in machines with robust construction and regularly perform maintenance to ensure spindle and axis alignment remain within tight tolerances.

Workpiece fixturing is another critical element that's often underappreciated. Inadequate workholding can allow the part to move or vibrate during machining, resulting in dimensional errors and poor surface finish. For complex side milling operations, we often design custom fixtures that provide maximum support while minimizing interference with tool paths.

Coolant application strategy directly impacts both part quality and tool life. Proper coolant delivery helps manage heat generation, flush away chips, and reduce friction between the tool and workpiece. For deep side milling operations, we frequently employ high-pressure coolant systems to ensure effective chip evacuation from the cutting zone.

| Factor | Impact on Quality | Optimization Approach |

|---|---|---|

| Tool Selection | High | Match tool geometry and material to workpiece requirements |

| Cutting Parameters | High | Balance speed, feed, and depth based on material and tool |

| Machine Rigidity | Medium-High | Maintain equipment and select appropriate machines |

| Workpiece Fixturing | Medium-High | Design custom workholding for complex geometries |

| Coolant Application | Medium | Use directed high-pressure coolant for deep features |

How to Optimize Parameters and Strategies in Side Milling?

Are your side milling operations taking too long or producing subpar results? The right optimization approach can transform both efficiency and quality, but requires a systematic methodology.

Optimizing side milling involves selecting appropriate cutting tools, implementing climb milling where possible, using adaptive cutting depths, employing trochoidal tool paths for slots, and applying high-efficiency machining strategies that maintain consistent tool engagement.

Optimized side milling strategy in action

Over my years managing our CNC department, I've developed several proven strategies for optimizing side milling operations. These approaches have consistently helped us reduce cycle times while improving part quality across diverse applications.

Tool selection forms the foundation of any optimization effort. For aluminum components, we typically use fewer-fluted tools (2-3 flutes) that provide excellent chip evacuation, while steel and harder materials benefit from more flutes (4+) for stability. The tool's length-to-diameter ratio should be kept as low as practically possible—we avoid using tools that extend more than 4-5 times their diameter without additional support.

Cutting direction plays a crucial role in optimization. We've found that climb milling (where the cutter rotates in the direction of the feed) generally produces better surface finish and reduces tool wear compared to conventional milling. When machining vacuum chamber components with thin walls, this approach helps minimize deflection and vibration by directing cutting forces into the workpiece.

Depth of cut strategies significantly impact machining efficiency. Rather than taking a single deep cut, we often employ adaptive depth strategies where the tool engages at full diameter but with varying depth. This approach maintains more consistent cutting forces and reduces the risk of tool breakage. For deep pockets, we implement a progressive depth strategy with decreasing step-downs as the feature gets deeper.

Tool path optimization has revolutionized our side milling operations. Trochoidal milling—where the tool follows a circular path while gradually advancing—allows for much higher material removal rates while reducing tool stress. For long straight slots, this approach has reduced our machining time by up to 40% while extending tool life. Similarly, adaptive clearing strategies maintain consistent tool engagement by adjusting the cutting path based on material conditions.

Entry strategies deserve careful consideration to prevent tool damage. We avoid plunging directly into the material when possible, instead using helical or ramping approaches that gradually engage the cutting edges. For closed pockets, we often pre-drill entry points to eliminate the need for plunging altogether.

| Optimization Area | Strategy | Benefit |

|---|---|---|

| Tool Selection | Match flute count to material | Improved chip evacuation and cutting efficiency |

| Cutting Direction | Implement climb milling | Better surface finish and reduced tool wear |

| Depth Strategy | Use adaptive or progressive depths | Consistent cutting forces and reduced deflection |

| Tool Path | Apply trochoidal or adaptive clearing | Higher removal rates with lower tool stress |

| Entry Method | Utilize helical or ramping approaches | Reduced tool damage and extended life |

Conclusion

Side milling remains essential to CNC machining because it uniquely combines versatility, precision, and efficiency for creating complex geometries. By understanding its principles and optimizing your approach, you'll achieve superior results that meet the most demanding specifications.