Shipbuilders face mounting pressure to create vessels that are both stronger and lighter. Traditional manufacturing methods fall short, causing delays, waste, and compromising quality. CNC machining solves these critical challenges.

CNC machining revolutionizes shipbuilding by providing unmatched precision for critical components. It enables manufacturers to fabricate complex parts with exact specifications, ensuring structural integrity while reducing weight. This technology transforms how ships are built, making them safer, more efficient, and cost-effective.

CNC machining for shipbuilding

In my years working with shipbuilders, I've seen firsthand how CNC machining transforms production capabilities. Let me share why this technology has become the backbone of modern shipbuilding and how it's reshaping the entire industry.

How Does CNC Machining Enhance the Precision of Shipbuilding Components?

Shipbuilders once struggled with component inconsistencies that led to structural weaknesses. Manual fabrication methods couldn't achieve the tight tolerances modern vessels demand. CNC machining eliminated these dangerous shortcomings.

CNC machining delivers micron-level precision for critical shipbuilding components. The technology maintains consistent accuracy across large-scale production runs, ensuring perfect-fitting parts every time. This precision extends vessel lifespan by reducing stress points and improving structural integrity throughout the ship.

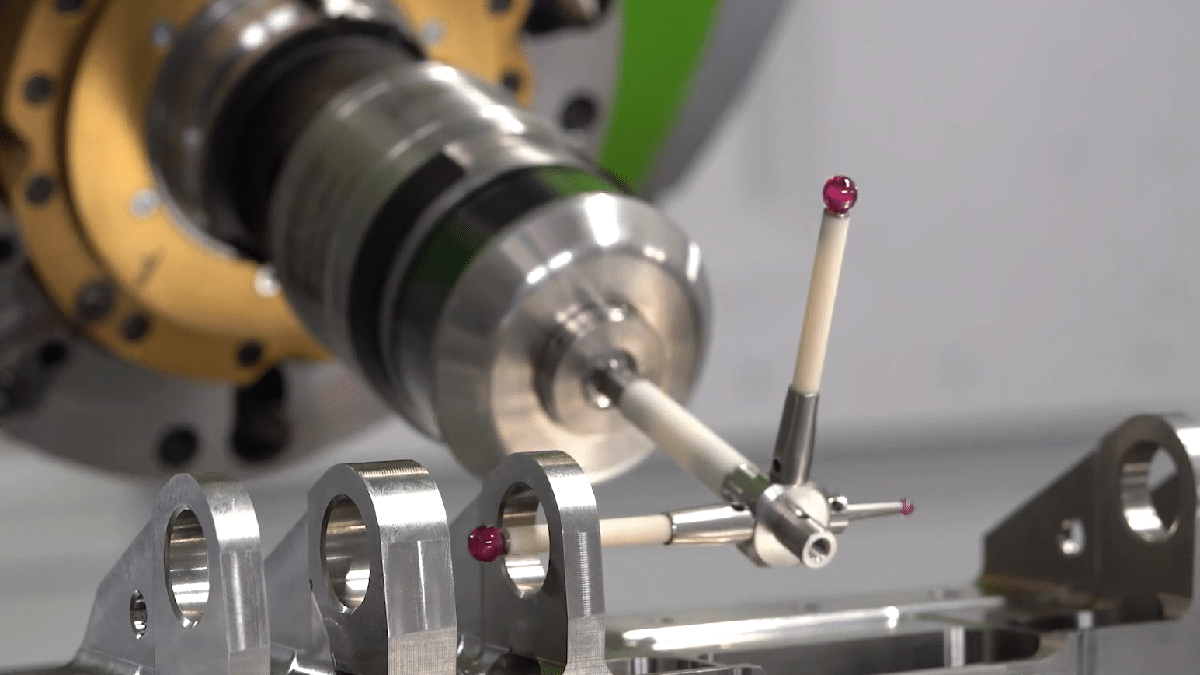

Precision measurement of CNC-machined ship parts

I recently worked with a luxury yacht manufacturer who needed propeller shafts with tolerances of ±0.005mm. Traditional methods simply couldn't deliver this level of precision, but our CNC machines handled it easily. The difference in precision between traditional and CNC machining is remarkable.

For shipbuilders, this precision matters in several key areas:

| Component Type | Traditional Tolerance | CNC Tolerance | Performance Impact |

|---|---|---|---|

| Propeller Shafts | ±0.5mm | ±0.005mm | 30% reduced vibration |

| Hull Plates | ±2mm alignment | ±0.2mm alignment | Improved hydrodynamics |

| Engine Mounts | ±1mm | ±0.01mm | Extended engine life |

The enhanced precision doesn't just improve fit and function—it directly impacts vessel performance. When hull components align perfectly, water resistance decreases, improving fuel efficiency. Precise engine mounts reduce vibration, extending component life and reducing maintenance costs. Even small improvements in tolerance add up to significant gains in overall vessel performance.

I've seen ships built with CNC-machined components lasting longer than their traditionally manufactured counterparts. The difference comes from eliminating the small imperfections that, over time, develop into serious structural issues.

What Are the Cost Benefits of Using CNC Machining in Shipbuilding?

Shipyard managers often worry about the high initial investment of CNC technology. They see only the upfront costs without understanding the long-term financial benefits. This shortsighted approach costs them significantly.

CNC machining reduces overall shipbuilding costs despite higher initial investment. It minimizes material waste through optimized cutting paths and reduces labor costs by automating repetitive tasks. The technology also cuts down expensive rework by achieving right-first-time production, resulting in long-term savings.

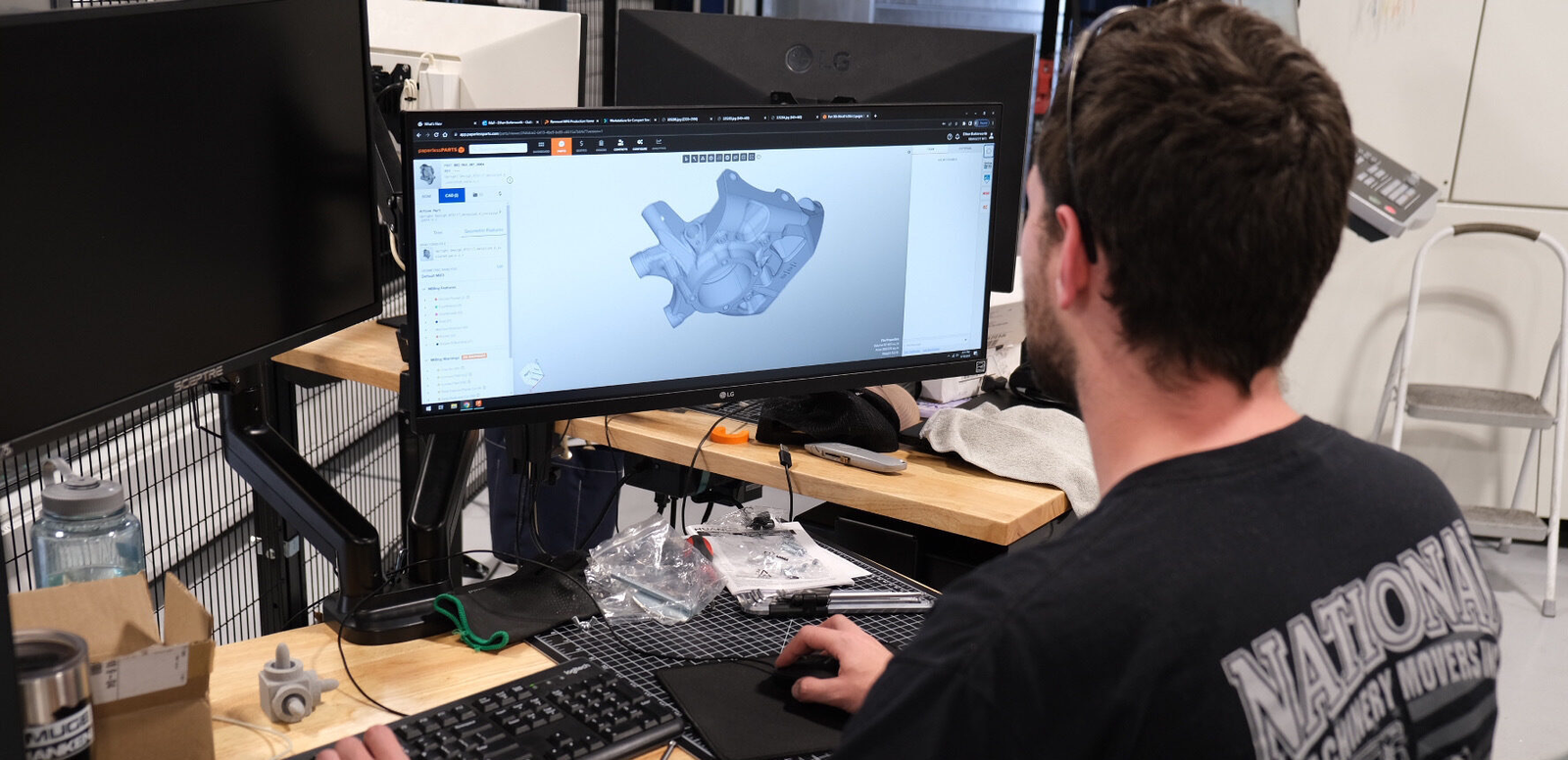

CNC programming for efficient material usage

When I first installed CNC machines in our workshop, I was concerned about justifying the investment. Within a year, the numbers spoke for themselves. The cost savings came from several areas that aren't immediately obvious.

Material waste reduction is perhaps the most visible benefit. Our CNC nesting software optimizes cutting patterns, reducing steel plate waste by up to 30% compared to manual methods. For large vessels requiring tons of material, these savings add up quickly.

| Cost Factor | Traditional Method | CNC Method | Savings |

|---|---|---|---|

| Material Waste | 15-25% | 5-8% | 10-17% |

| Labor Hours (per component) | 8-12 hours | 2-4 hours | 50-70% |

| Rework Rate | 7-15% | 1-2% | 5-13% |

| Production Time | Base reference | 40-60% faster | Faster delivery |

Labor costs also decrease dramatically. While CNC machines require skilled operators, one operator can manage multiple machines simultaneously. This multiplies productivity without proportionally increasing labor costs.

The reduction in errors and rework might be the most significant cost advantage. When parts are machined incorrectly, the costs cascade through the entire production process. I've seen single fitting errors delay vessel completion by weeks and cost thousands in rework. With CNC machining, these errors become extremely rare.

How Can Programming Optimize CNC Machining for Marine Environments?

Many shipbuilders struggle with corrosion and material compatibility issues in marine applications. Standard machining approaches often fail to address the unique challenges of salt exposure and constant moisture. Specialized programming solves these critical problems.

CNC programming for marine environments requires specialized parameter settings that address corrosion resistance and material durability. Optimized cutting speeds, tool paths, and finishing operations can enhance component longevity in harsh marine conditions. Proper programming also enables the effective machining of specialized marine-grade materials.

Specialized CNC programming for marine applications

When machining components for marine use, standard programming approaches often fall short. I learned this the hard way when some early parts we produced showed signs of corrosion much sooner than expected. We've since developed specialized programming approaches that address these unique challenges.

The first consideration is material-specific programming. Marine-grade stainless steels, bronzes, and specialized alloys each require different cutting parameters:

| Material | Cutting Speed Adjustment | Tool Life Consideration | Surface Finish Requirement |

|---|---|---|---|

| 316L Stainless | 15-20% slower than standard | Higher wear rate | Ra 0.4μm or better |

| Naval Brass | Standard speed with cooling | Low tool pressure | Ra 0.8μm |

| Duplex Stainless | 25-30% slower | Premium tooling required | Ra 0.6μm |

We've found that surface finish programming is particularly important for marine components. Microscopic surface irregularities can become initiation points for corrosion in saltwater environments. Our programs now include specialized finishing passes that create smoother surfaces, significantly enhancing corrosion resistance.

Tool path strategies also matter greatly. We program our machines to maintain consistent cutting forces, which prevents work hardening in critical areas of marine components. This approach has extended component lifespan by as much as 40% in high-stress applications like propeller shafts and rudder components.

How to Select Suitable CNC Equipment for Shipbuilding?

Shipyards often invest in the wrong CNC equipment, leading to capability gaps or unnecessary costs. Without understanding their specific needs, they end up with machines that can't handle their workload or are too complex for their requirements.

Selecting the right CNC equipment for shipbuilding requires matching machine capabilities to specific manufacturing needs. Consider work envelope size, axis capabilities, and power requirements based on typical component dimensions. Evaluate machine accuracy, repeatability, and ability to handle marine-grade materials for optimal results.

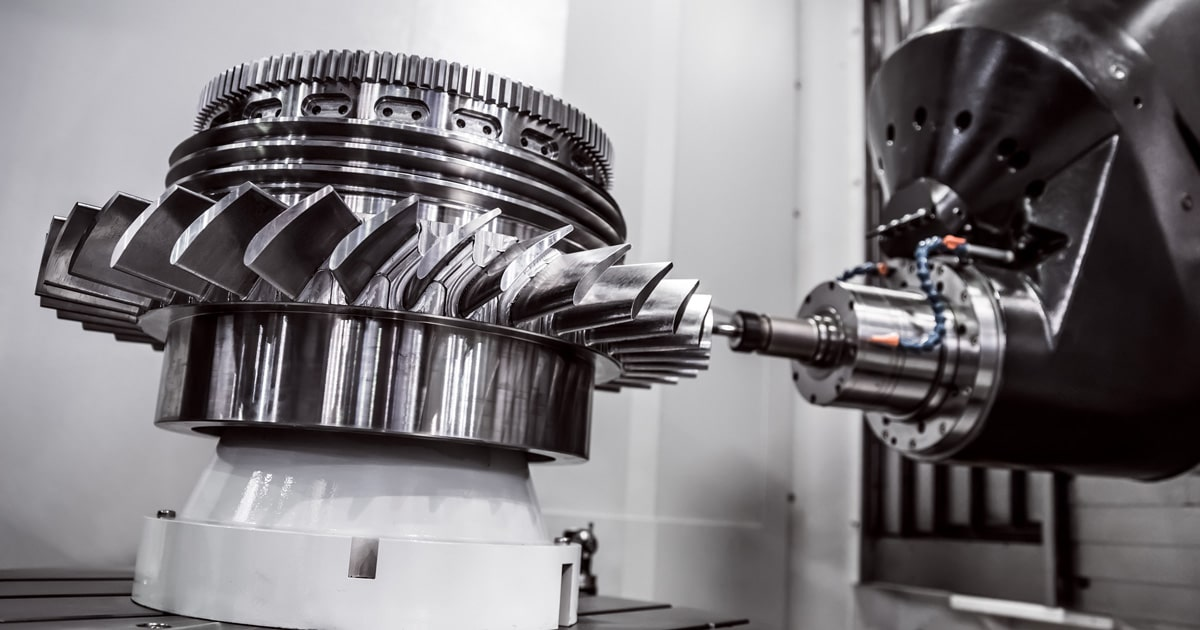

Large-scale CNC equipment for shipbuilding

When I was tasked with upgrading our CNC equipment, I found the options overwhelming. After some costly mistakes, I developed a systematic approach to equipment selection that has served us well.

Size requirements come first. Shipbuilding often involves large components, so the working envelope of your CNC machine must accommodate your largest regular parts. We found that having one larger machine for hull components and several smaller machines for detail parts provided the best workflow balance.

| Ship Type | Typical Component Size | Recommended Machine Envelope | Key Features |

|---|---|---|---|

| Small Boats | Up to 2m components | 3m × 2m × 1m | 3-axis sufficient |

| Yachts | Up to 5m components | 6m × 3m × 2m | 5-axis beneficial |

| Commercial Vessels | Up to 10m+ components | 12m × 4m × 3m | 5-axis essential |

Power and rigidity are critical factors often overlooked. Marine-grade materials like duplex stainless steel require significant cutting force. Machines with insufficient rigidity will vibrate during cutting, reducing precision and tool life. We upgraded to machines with cast iron frames and reinforced guide rails, which dramatically improved our cutting performance on tough materials.

Control systems matter more than many realize. We chose machines with controls that could handle complex 3D geometries for hull components. The ability to import CAD files directly into the machine control saved us countless hours of programming time and reduced errors significantly.

How to Ensure Efficient Application of CNC Machining in Shipbuilding?

Many shipbuilders implement CNC technology but fail to optimize their workflows around it. They retain inefficient processes that negate the benefits of their investment. This wastes potential and limits return on investment.

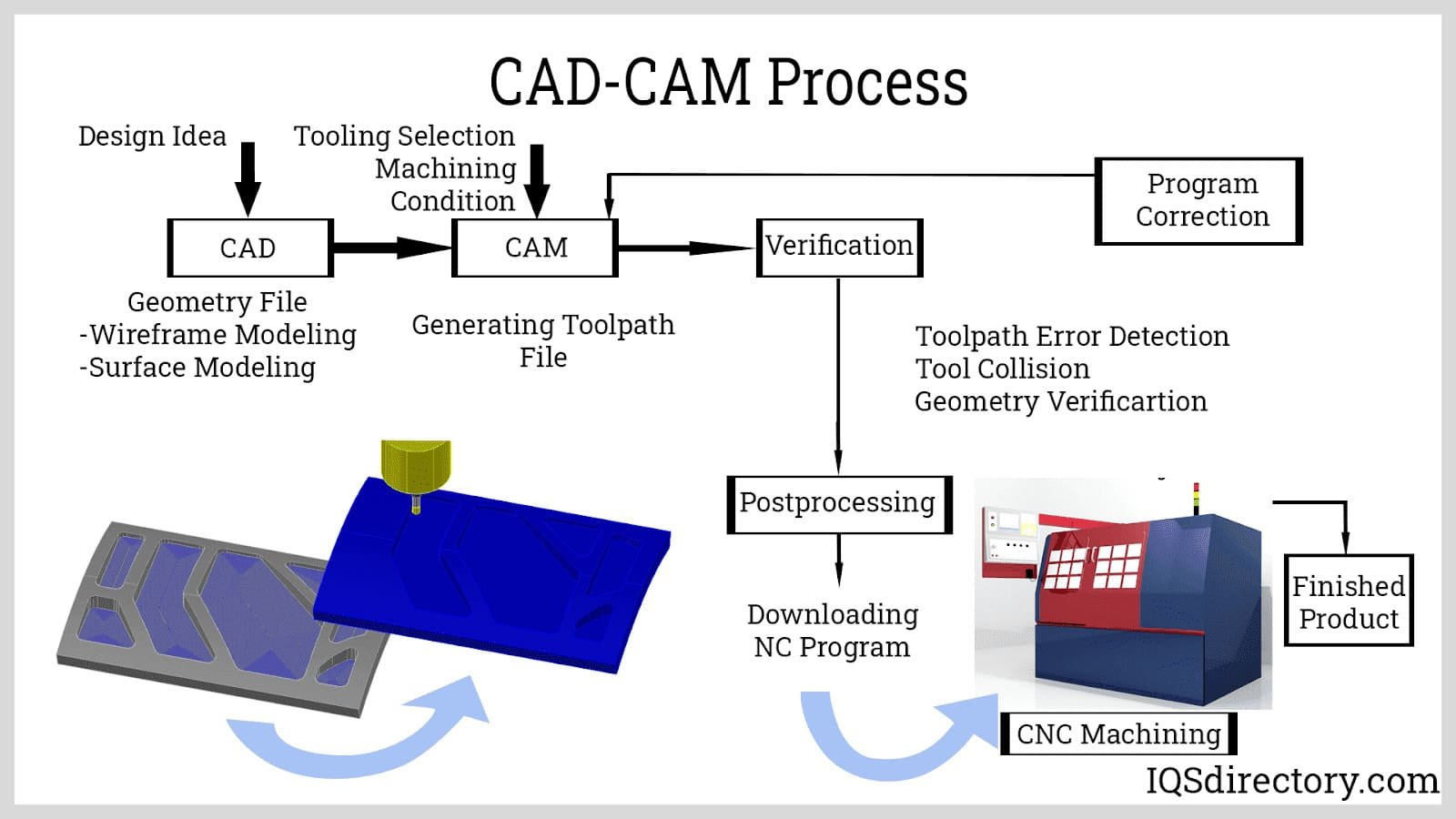

Maximizing CNC efficiency in shipbuilding requires integrating the technology into a comprehensive workflow. Implement digital design-to-manufacturing pipelines that minimize data translation errors. Develop standardized procedures for material handling, fixturing, and quality control to ensure consistent output and minimize machine downtime.

Integrated CNC workflow in shipbuilding

The efficiency of CNC machining doesn't just depend on the machines—it's about creating systems that support them. In our facility, we completely redesigned our workflow when we introduced CNC technology, and the results were transformative.

Material handling is a critical factor. We installed overhead cranes and custom fixturing systems to minimize setup time for large components. What once took hours now takes minutes, significantly increasing our machine utilization rates. We also implemented barcode tracking for all materials, which reduced errors and improved traceability.

| Process Phase | Traditional Approach | Optimized CNC Approach | Efficiency Gain |

|---|---|---|---|

| Design Transfer | Manual interpretation | Direct CAD-to-CAM | 90% time reduction |

| Setup Time | 2-3 hours per component | 20-30 minutes | 80% time reduction |

| Quality Verification | Manual measurement | Automated CMM inspection | 70% time reduction |

| Documentation | Paper-based | Digital with component tracking | Complete traceability |

Training is another essential element. We invested in comprehensive training programs for both operators and designers. Our designers learned to create "CNC-friendly" designs that minimize complex setups, while operators became skilled at optimizing cutting parameters on the fly based on material behavior.

We also implemented preventive maintenance schedules based on machine usage rather than calendar time. This approach reduced unexpected downtime by nearly 80% and extended machine life significantly. The small cost of regular maintenance pays enormous dividends in productivity and reliability.

Conclusion

CNC machining has transformed modern shipbuilding by delivering unprecedented precision, cost efficiency, and material optimization. By implementing the right equipment, programming, and workflows, shipbuilders can create vessels that are stronger, lighter, and more durable than ever before.