Are you struggling with excessive tool wear and high machining costs? Soft machining could be the solution you're overlooking, offering dramatic improvements in production efficiency while extending tool life.

Soft machining is the process of cutting materials in their annealed or pre-hardened state, before they undergo heat treatment. This approach allows for faster material removal rates, reduced tool wear, and lower machining costs while maintaining tight tolerances and excellent surface finishes for precision components.

In my years running a CNC machining factory, I've seen countless projects transformed by choosing the right machining approach. The distinction between soft and hard machining isn't just academic—it can make or break your production timeline and budget. Let's explore why soft machining might be your best option for precision components.

What Materials Are Best Suited for Soft Machining Processes?

Are your material choices causing unnecessary manufacturing headaches? Selecting the right materials for soft machining can dramatically reduce production time and extend tool life.

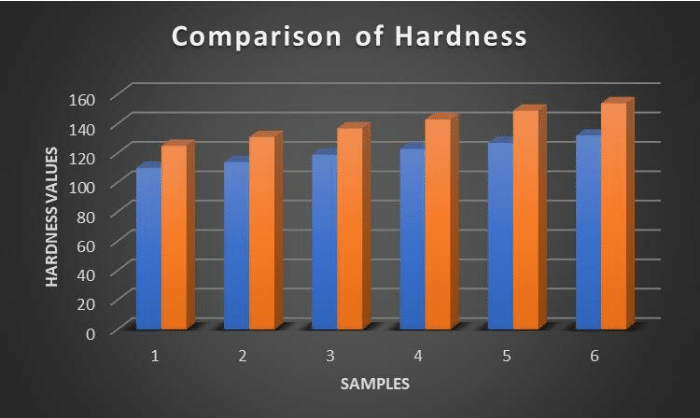

Soft machining excels with materials in their annealed or normalized state, including low and medium-carbon steels, aluminum alloys, copper alloys, and pre-hardened tool steels up to approximately 30-35 HRC. These materials offer optimal chip formation, reduced cutting forces, and superior surface finishes during machining.

Common soft machining materials

Material selection is a critical factor in successful soft machining operations. From my experience working with clients across multiple industries, I've found that understanding material properties before machining begins can prevent costly mistakes down the production line.

The machinability of materials varies significantly based on their composition and pre-processing conditions. For example, free-cutting steels containing sulfur or lead additives offer excellent chip breaking and tool life during soft machining operations. Aluminum alloys in the 6000 series provide an optimal balance of strength and machinability, making them ideal candidates for soft machining processes.

Here's a breakdown of common materials and their suitability for soft machining:

| Material Type | Machinability Rating | Typical Hardness Range | Best Applications |

|---|---|---|---|

| 1018 Steel | Good | 120-150 HB | Automotive components, general hardware |

| 6061 Aluminum | Excellent | 30-40 HB | Aerospace parts, marine components |

| C36000 Brass | Excellent | 60-90 HB | Plumbing fittings, electrical components |

| 4140 Steel (annealed) | Moderate | 180-220 HB | Gears, shafts, mechanical components |

| 316 Stainless (annealed) | Fair | 160-190 HB | Food processing equipment, marine parts |

Pre-treatment processes like annealing and normalizing can significantly improve machinability by reducing internal stresses and creating a more uniform microstructure. When working with tougher alloys like stainless steel or titanium, these preparatory steps become even more crucial for successful soft machining operations.

How Does Soft Machining Compare to Hard Machining in Cost and Performance?

Wondering why your machining costs keep climbing while productivity falls? The choice between soft and hard machining could be the key factor impacting your bottom line.

Soft machining typically offers 3-5 times higher material removal rates than hard machining, with tool life often extended by 200-300%. While hard machining provides superior dimensional stability and wear resistance, soft machining delivers significantly lower production costs and faster turnaround times.

Soft vs hard machining tool comparison

The economics of machining processes can make or break a manufacturing business. In our factory, we've consistently found that the choice between soft and hard machining represents one of the most significant cost variables in production planning.

Soft machining offers distinct advantages in several critical areas. First, the cutting tools used can be less expensive, as they don't require specialized coatings or materials designed to withstand extreme hardness. Standard high-speed steel (HSS) or carbide tools often suffice for soft machining operations, whereas hard machining may require cubic boron nitride (CBN) or polycrystalline diamond (PCD) tooling at substantially higher costs.

Processing speeds present another stark contrast. In a recent automotive component project, we achieved material removal rates three times higher with soft machining compared to hard machining the same material post-heat treatment. This translated to significantly reduced machine time and lower energy consumption.

Consider these performance metrics from our production data:

| Performance Metric | Soft Machining | Hard Machining |

|---|---|---|

| Material Removal Rate | 100-500 cm³/min | 5-50 cm³/min |

| Tool Life | 100-300 minutes | 15-60 minutes |

| Surface Finish Capability | 0.8-3.2 μm Ra | 0.2-0.8 μm Ra |

| Dimensional Tolerance | ±0.05 mm | ±0.01 mm |

| Energy Consumption | Lower | Higher |

| Setup Complexity | Simpler | More complex |

The trade-off comes in the final component properties. Hard machining allows for working with materials already at their optimal hardness, eliminating the need for subsequent heat treatment and the potential distortion that can occur. However, for many applications, the cost advantages of soft machining followed by controlled heat treatment outweigh these concerns.

Which Industries Benefit Most from Soft Machining Techniques?

Is your industry missing out on the competitive advantages of optimized manufacturing processes? Certain sectors stand to gain tremendous benefits from implementing soft machining techniques.

Industries with high-volume production requirements and complex geometries—including automotive, aerospace, medical device manufacturing, and heavy equipment—benefit most from soft machining. These sectors leverage soft machining to reduce production costs while maintaining the ability to achieve precise specifications after subsequent heat treatment.

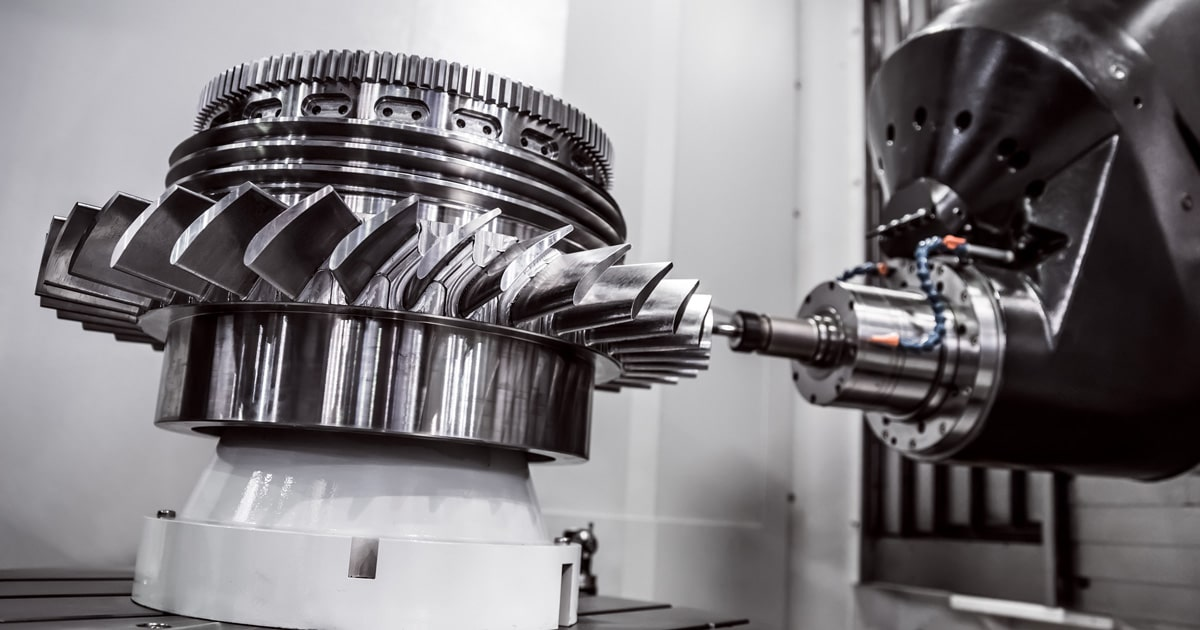

Automotive components made with soft machining

The adoption of soft machining varies significantly across different sectors, often correlating with production volume and material requirements. Having worked with clients across multiple industries, I've observed patterns in how different sectors leverage this manufacturing approach.

The automotive industry represents one of the largest beneficiaries of soft machining techniques. Engine components, transmission parts, and suspension systems typically require both precision and durability, making them ideal candidates for soft machining followed by heat treatment. One automotive client reduced their production costs by 22% after switching to a soft machining process for their transmission components.

Aerospace manufacturing presents another compelling case for soft machining, particularly for structural components and landing gear parts. The complex geometries common in aerospace applications are often easier to achieve in softer materials, with subsequent heat treatment providing the necessary strength properties. The weight reduction possibilities through precision machining also make this approach valuable for fuel efficiency improvements.

Medical device manufacturing has unique requirements that align well with soft machining capabilities:

| Medical Component | Soft Machining Benefit | Critical Requirements |

|---|---|---|

| Orthopedic Implants | Complex anatomical shapes | Biocompatibility, fatigue resistance |

| Surgical Instruments | Precise cutting edges | Sterilizability, corrosion resistance |

| Imaging Equipment Parts | Tight tolerances | Non-magnetic properties, stability |

| Dental Components | Custom geometries | Biocompatibility, aesthetics |

The semiconductor industry also leverages soft machining for vacuum chamber components and precision fixtures. The ability to create intricate cooling channels and precise mounting features in vacuum chamber walls before final hardening ensures both functionality and longevity in these demanding applications.

Heavy equipment manufacturers benefit from soft machining, particularly for large components where hard machining would be prohibitively expensive or time-consuming. Components like hydraulic manifolds, valve bodies, and structural elements can be rough machined in their soft state, heat-treated, and then finish machined only in critical areas to minimize cost.

What Are the Key Soft Machining Methods for Custom CNC Parts?

Are your current machining methods failing to deliver the efficiency and quality your custom parts demand? Understanding the right soft machining technique for each application can transform your production outcomes.

The principal soft machining methods include CNC turning for cylindrical parts, milling for complex geometries, drilling for precision holes, and grinding for superior surface finishes. Each process offers specific advantages in material removal rates, surface quality, and dimensional accuracy when working with pre-hardened materials.

CNC milling soft machining process

Having implemented countless custom machining solutions in our factory, I've seen firsthand how selecting the appropriate soft machining method can dramatically impact project outcomes. Each technique has distinct advantages depending on the part geometry and quality requirements.

CNC turning remains the most efficient process for creating cylindrical and round features in soft materials. The continuous cutting action allows for rapid material removal with excellent surface finish. For example, when manufacturing custom sailboat winch components from 6061 aluminum, we achieved material removal rates three times higher than comparable hard machining processes, with surface finishes averaging 0.8μm Ra without additional finishing operations.

Milling operations offer unparalleled versatility for creating complex 3D geometries in soft materials. Modern high-speed machining centers can maintain tight tolerances while removing material at impressive rates. Multi-axis capabilities further enhance this advantage by allowing complex features to be machined in a single setup, reducing handling errors and improving dimensional accuracy.

Advanced soft machining methods incorporate specialized techniques:

| Machining Method | Best Application | Typical Tolerances | Material Removal Rate |

|---|---|---|---|

| High-Speed Milling | Complex contours, thin walls | ±0.025mm | 100-500 cm³/min |

| Deep-Hole Drilling | Precision holes >10x diameter | ±0.05mm | Depends on diameter |

| Thread Milling | Internal/external threads | Class 2 fit | 50-200 cm³/min |

| Precision Turning | Cylindrical features, shafts | ±0.01mm | 100-400 cm³/min |

| Profile Grinding | Precision profiles, contours | ±0.005mm | 5-20 cm³/min |

CAM software optimization plays a crucial role in maximizing the effectiveness of these methods. Advanced toolpath strategies like trochoidal milling and adaptive clearing have revolutionized soft machining by maintaining consistent tool engagement, reducing vibration, and extending tool life. In a recent project manufacturing vacuum chamber components, implementing optimized toolpaths reduced our machining time by 40% while improving surface finish quality.

Tool selection also significantly impacts soft machining performance. Variable helix end mills have proven particularly effective for minimizing chatter in soft materials, while specialized drill geometries with improved chip evacuation can dramatically increase drilling efficiency and hole quality in materials like aluminum and pre-hardened steels.

When Should You Choose Soft Machining Over Alternative Manufacturing Processes?

Are your manufacturing decisions based on habit rather than optimization? The choice between soft machining and alternative processes should be strategic, not just traditional.

Soft machining is the optimal choice when dealing with complex geometries that would be difficult to achieve in hardened materials, when production volumes justify the efficiency gains, or when material properties require a combination of machinability and post-treatment hardness. It's particularly advantageous when compared to casting or forging for medium-volume, precision-critical components.

Before and after heat treatment comparison

Making the right manufacturing process selection requires careful analysis of multiple factors. Throughout my career, I've helped customers navigate these decisions by evaluating their specific requirements against the capabilities of different manufacturing approaches.

The decision to use soft machining often hinges on part complexity and production volume. For simple geometries produced in high volumes, processes like casting or forging may prove more economical. However, as geometries become more complex—featuring internal cavities, precise threading, or tight tolerance features—soft machining becomes increasingly advantageous.

The material's final application requirements also play a decisive role. Components requiring both complex geometries and high hardness (like tooling inserts or wear components) benefit tremendously from soft machining followed by heat treatment. This approach allows manufacturers to achieve geometrical complexity that would be prohibitively expensive or technically impossible in already-hardened materials.

Consider these decision factors when evaluating soft machining against alternatives:

| Factor | Favor Soft Machining When | Consider Alternatives When |

|---|---|---|

| Part Complexity | High complexity with precise features | Simple geometry with minimal features |

| Production Volume | Low to medium volumes (10-10,000 units) | Very high volumes (>100,000 units) |

| Material Requirements | Need for both machinability and final hardness | Either machinability or hardness alone is sufficient |

| Tolerance Requirements | Moderate to tight tolerances (±0.05mm) | Ultra-precise tolerances (<±0.005mm) |

| Lead Time | Long lead times are acceptable | Long lead times acceptable |

| Design Flexibility | Rapid prototyping or quick turnaround is needed | Design is finalized and stable |

Case in point: When manufacturing critical automotive transmission components, we initially considered investment casting followed by minimal machining. However, analysis revealed that soft machining followed by carburizing heat treatment would provide superior dimensional control while allowing for mid-production design refinements. Though the per-part machining cost was higher, the elimination of expensive tooling changes and improved quality control justified the soft machining approach.

Additive manufacturing presents an interesting comparison point. While 3D printing excels at creating complex internal geometries that might challenge even soft machining processes, it often struggles with surface finish and dimensional accuracy compared to CNC soft machining. For components requiring both complex geometries and precise tolerances, a hybrid approach sometimes proves optimal—using additive processes for near-net shapes followed by soft machining of critical features.

Conclusion

Soft machining offers substantial advantages in efficiency, tool life, and cost-effectiveness when producing precision components. By matching the right materials, methods, and manufacturing sequence to your specific requirements, you can optimize production while achieving superior results.