Profile milling is a versatile CNC machining technique essential for creating complex geometries and contoured surfaces with high precision. The ability to produce intricate profiles while maintaining dimensional accuracy and superior surface finishes makes it significant in various industries.

Profile milling offers the capability to mold materials into complex 3D geometries, a critical factor in manufacturing aerospace components and medical implants. The application versatility of this technique supports industries requiring high-tolerance manufacturing where traditional methods fall short.

Profile milling's growing importance is due to its precision in creating lightweight, complex components, boosted by advances in CAM software and multi-axis milling. Understanding its capabilities is crucial for optimizing design and manufacturing efficiency.

How Does Profile Milling Differ From Other Machining Methods?

In CNC manufacturing, not all processes are created equal. Each serves a unique purpose, affecting the choice of technique based on the application's needs and design complexity.

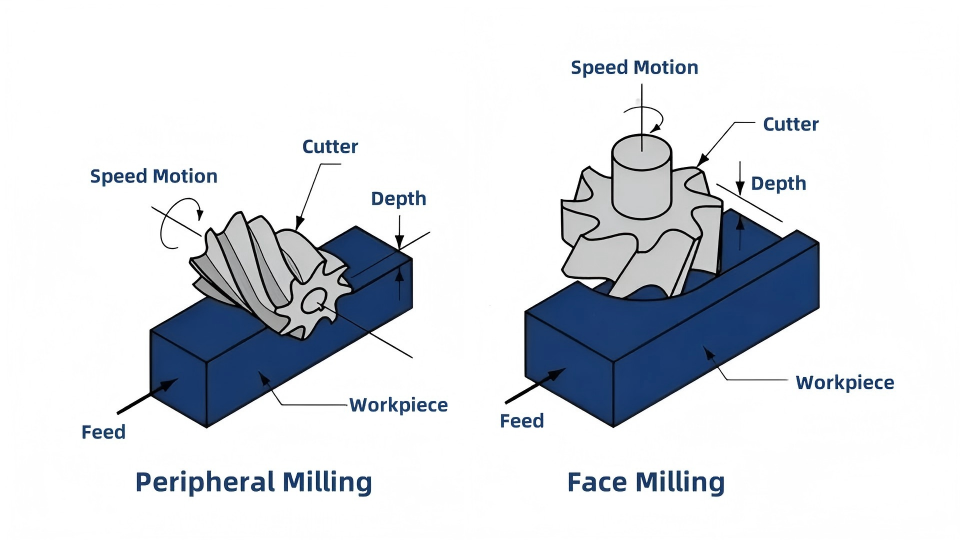

Profile milling involves a rotating multi-point cutting tool which allows for material removal in complex shapes and contours. Unlike other methods like turning, where the workpiece rotates, profile milling is ideal for intricate designs on stationary workpieces.

Profile milling stands apart for its flexibility in machining complex contours, enabled by modern CAM software that optimizes tool paths and reduces machining time. This capability is invaluable across industries like aerospace and automotive, where precision and complex geometries are paramount. Understanding distinctions between methods ensures the best-fit application in manufacturing projects.

What Are the Common Types of Profile Milling Operations?

Milling operations can be diverse, each designed to tackle specific challenges and applications. Knowing the options can optimize manufacturing processes and outcomes.

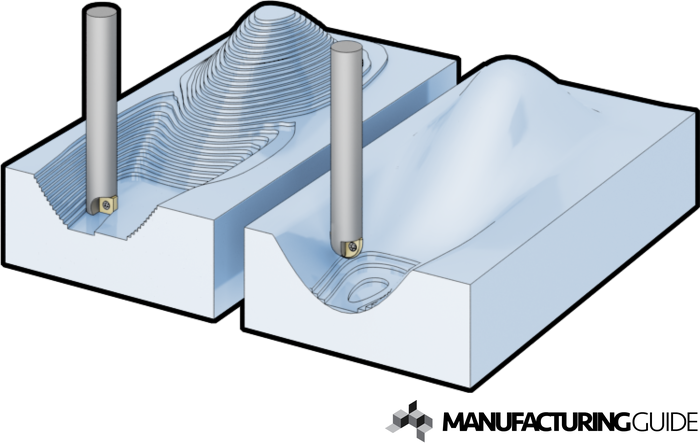

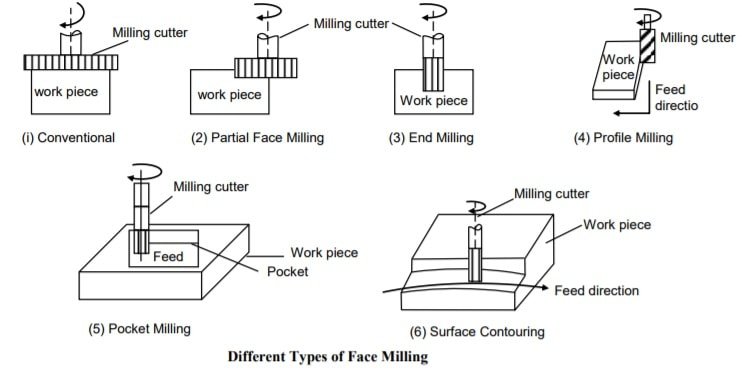

Profile milling includes operations such as contouring, slotting, and pocketing. These are vital for creating precise shapes and features in parts requiring high-quality finishes and complex geometries.

Understanding different operations allows manufacturers to select techniques that align with specific project requirements, ensuring efficient production of intricate components. The ability to handle variants like contouring or pocketing provides a competitive edge in delivering precise and customized solutions in high-demand industries.

Which Materials Are Best Suited for Profile Milling?

Material choice significantly impacts milling performance, influencing machining strategies and outcomes. Each material presents unique challenges that necessitate tailored approaches.

Profile milling accommodates various materials, including metals like aluminum, steel, and titanium, and plastics like nylon and polycarbonate. These materials are chosen for their machinability, strength, and suitability for complex geometries.

Selecting suitable materials for profile milling requires understanding their properties and the intended application's requirements. Distinct challenges, such as titanium's hardness versus aluminum's flexibility, dictate specific adjustments in milling parameters to achieve optimal results and ensure high-quality output.

How Do You Choose Between 3-Axis and 5-Axis Profile Milling?

The choice between different milling axes impacts precision, complexity, and machining efficiency. Making the right choice can enhance production capabilities.

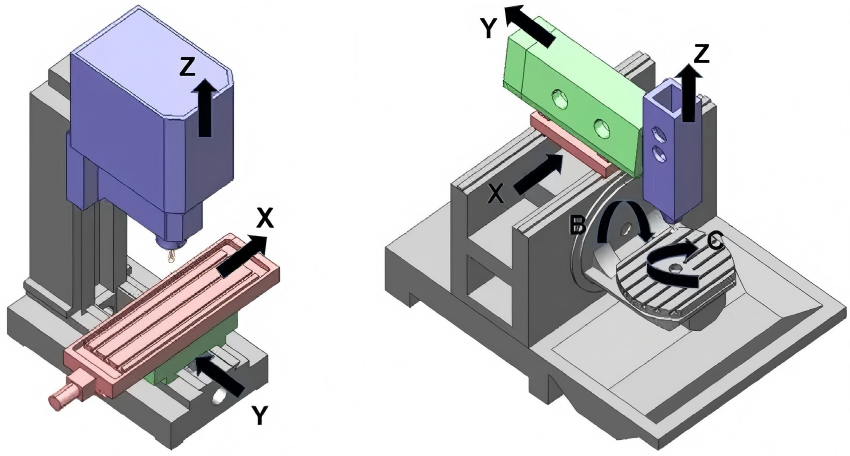

3-axis milling, operating along the X, Y, and Z axes, suits relatively simple geometries, while 5-axis milling adds rotations around two additional axes for greater flexibility. It facilitates manufacturing from multiple angles in a single setup, ideal for complex and intricate parts.

Understanding when to use 3-axis versus 5-axis profile milling revolves around the complexity of the design and precision requirements. While 5-axis machines offer unmatched flexibility and efficiency, they may necessitate higher initial investments, making the choice dependent on specific project and budget considerations.

What Are the Cost Considerations When Using Profile Milling?

Cost is always a concern in manufacturing. Balancing quality with budget constraints ensures competitive and viable production.

While profile milling involves higher initial costs due to machine complexity and setup, it often reduces overall assembly expenses by enabling the production of complex single-piece components. This reduces the need for additional processes.

Economically, profile milling offers long-term benefits by streamlining production, improving part quality, and reducing waste. Analyzing these factors helps align production strategies with budget constraints, ensuring efficient and cost-effective manufacturing solutions.

Conclusion

Profile milling's precise, flexible approach suits high-tolerance industries by creating complex geometries, expanding its significance in various manufacturing sectors.