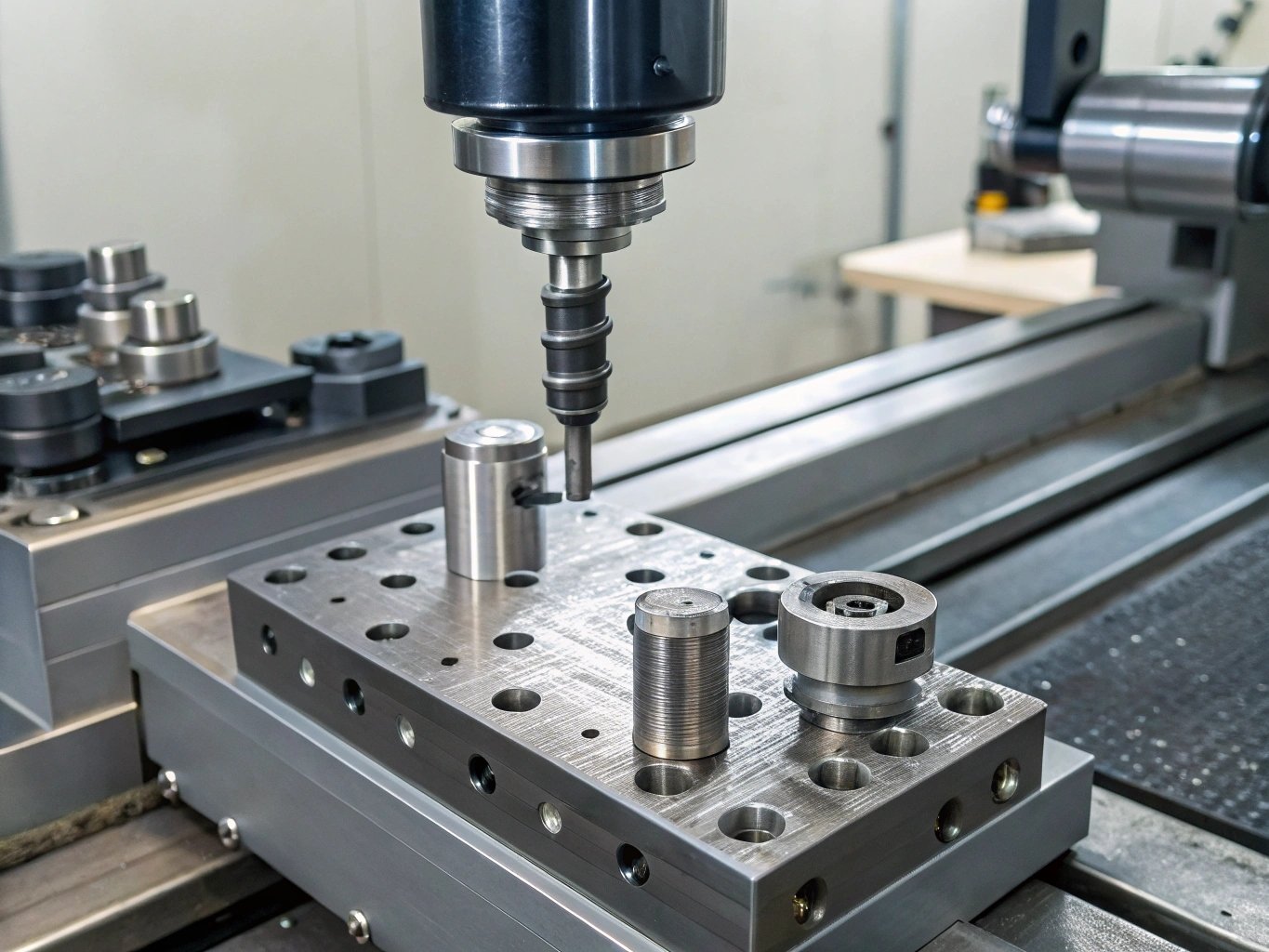

Properly securing a workpiece during CNC machining is vital. Any movement can lead to inaccuracies, affecting the final product's quality.

Workholding ensures parts remain stable, allowing precise machining. It involves devices and methods to keep the workpiece in place, directly impacting the quality and efficiency of the machining process 2.

Understanding the workholding's importance aids in delivering precision machined parts, a crucial factor for maintaining high standards.

What are the key elements of effective workholding in precision machining?

Inadequate workholding can result in costly errors or equipment damage. Secure, well-aligned holding is vital 1.

Effective workholding includes clamping force, support, location, and stability. These elements ensure proper positioning, preventing deformation and allowing accurate machining 2.

Key factors are clamping force and stability, both critical for achieving optimal precision and reliability in machining operations.

How do different workholding methods affect machining accuracy?

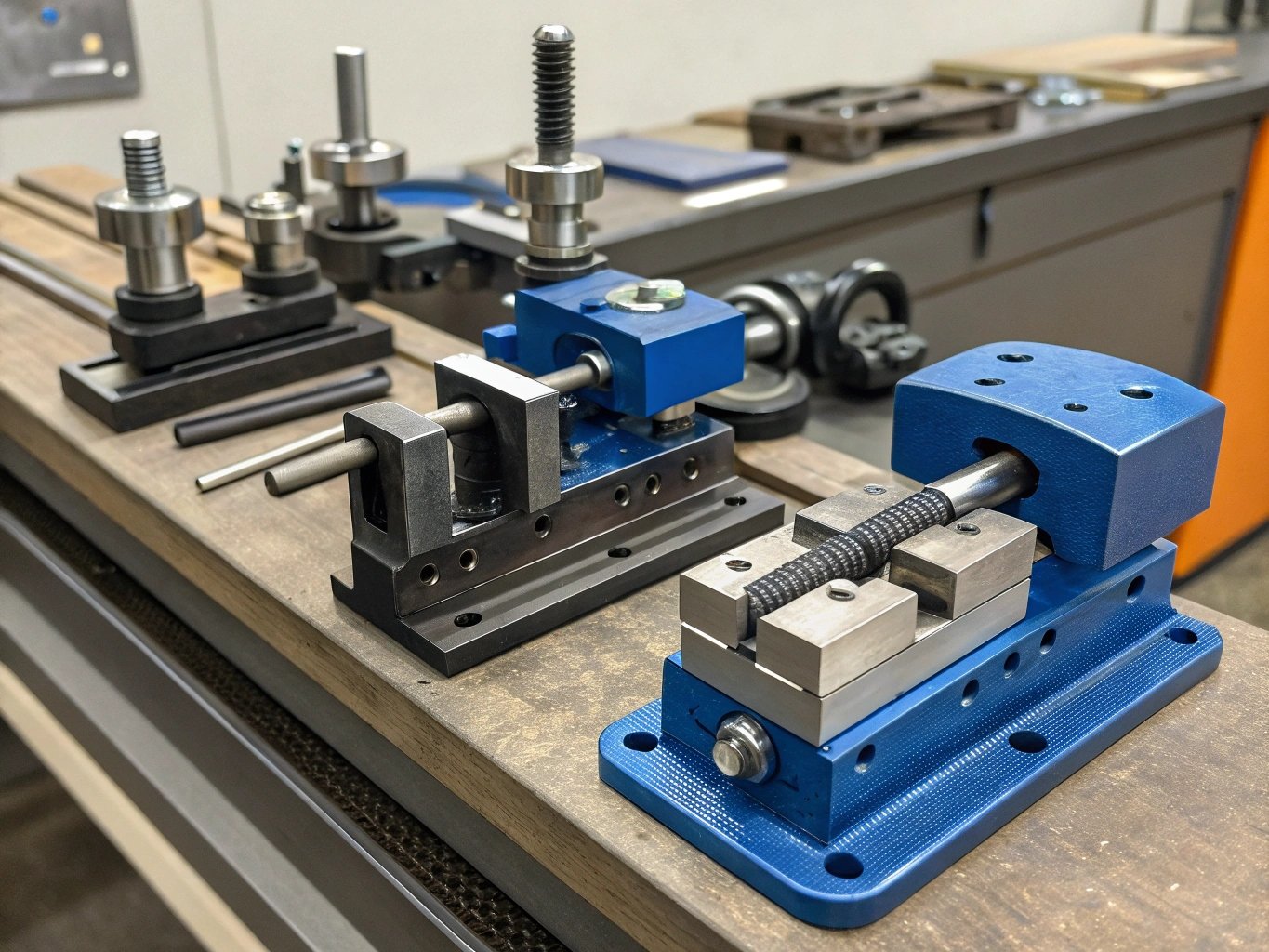

Workholding methods must fit the specific machining operation. Incorrect methods can lead to inefficiencies or part damage 3.

Different workholding methods, like vises, chucks, or clamps, directly influence machining accuracy. Proper selection reduces movement and vibration, ensuring precision in the final product 4.

Choosing the correct workholding for each operation is crucial, as it directly influences the precision and quality of the machining output.

Which workholding solutions are best for difficult-to-machine materials?

Machining challenging materials requires robust methods. Predicting issues with workholding can save time and resources 3.

For difficult materials, solutions like vacuum chucks or magnetic workholding minimize deformation. They offer stability without exerting excessive clamping force, ideal for delicate parts 5.

Selecting suitable solutions based on material properties ensures that challenging parts are machined without compromising quality or precision.

Conclusion

Understanding and implementing effective workholding is essential in CNC machining, significantly affecting precision and part quality.