How Does CNC Machining Improve Packaging Equipment Performance?

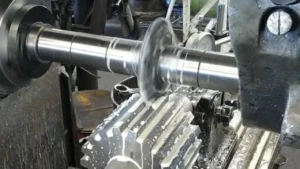

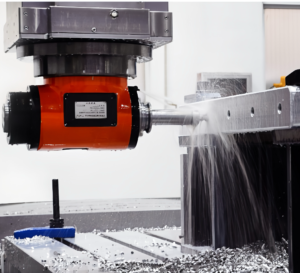

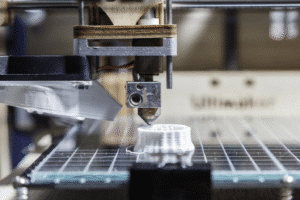

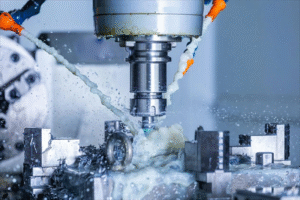

Precision CNC machining transforms packaging equipment performance through optimized materials, tight tolerances, sanitary designs, and advanced assembly techniques. Our integrated approach delivers components that maximize uptime, ensure product safety, and provide lasting reliability in demanding production environments.