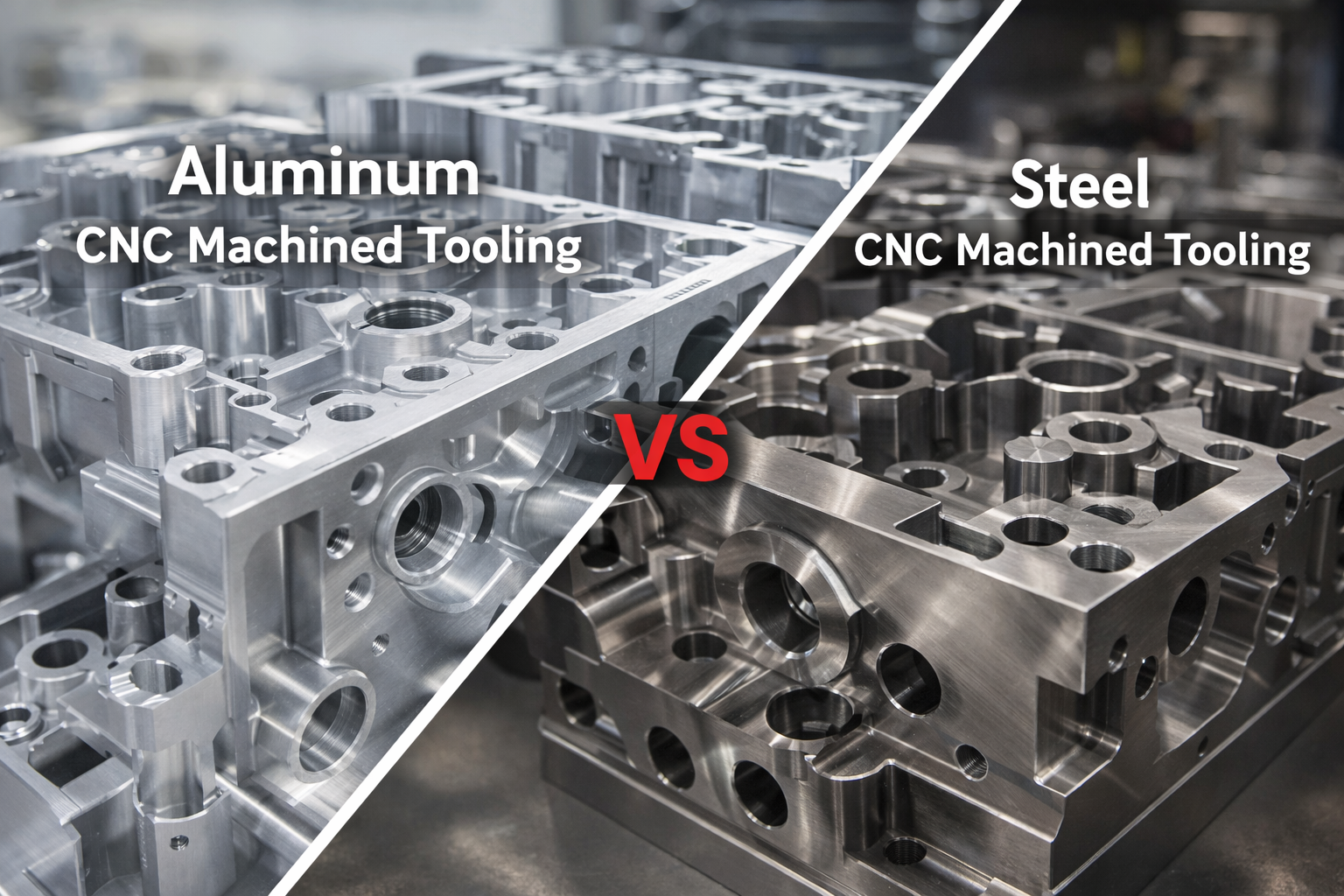

Tooling material selection can make or break your production timeline and budget. Many manufacturers struggle with this decision, balancing immediate costs against long-term performance needs.

Aluminum tooling typically offers 30-50% lower upfront costs and 2-3x faster machining times compared to steel, making it ideal for prototypes and low-volume production. Steel tooling provides superior durability and precision for high-volume applications despite a higher initial investment.

I've seen firsthand how material selection impacts production efficiency and costs. Let me share what I've learned from producing thousands of custom-machined components in both materials. Understanding these differences will help you make better decisions for your specific manufacturing needs.

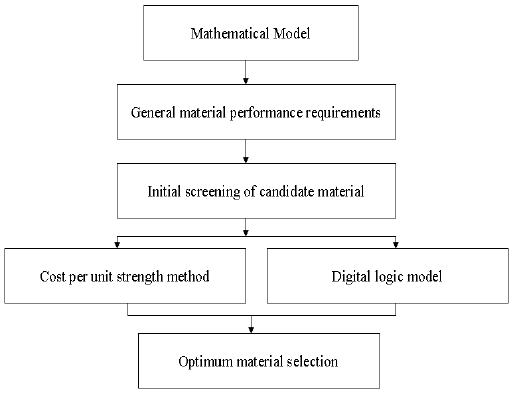

How Do Material Properties Impact Your Production Efficiency and Cost?

Production efficiency suffers when you choose the wrong material. I've watched clients waste thousands on steel tooling for short runs where aluminum would have delivered comparable results at half the cost.

Material properties directly affect machining speed, tool wear, and production cycle times. Aluminum cuts 2-3 times faster than steel with less tool wear, reducing machining costs by 40-60%. However, steel maintains tighter tolerances over extended production runs and withstands higher mechanical stresses.

Production Speed Comparison Between Aluminum and Steel

Material selection impacts every aspect of your manufacturing process. When evaluating aluminum versus steel, you need to consider several key properties that directly influence production efficiency:

Material Hardness and Machinability

The difference in hardness between aluminum and steel dramatically impacts machining operations. Aluminum alloys like 6061-T6 (with a Brinell hardness of 95) machine much faster than even mild steel (Brinell 120-200), not to mention hardened tool steels (Brinell 300+). In our factory, we typically achieve cutting speeds of 500-1000 SFM with aluminum compared to just 100-300 SFM with steel.

| Material | Brinell Hardness | Typical Cutting Speed (SFM) | Tool Wear Rate | Machining Time Ratio |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95 | 500-1000 | Low | 1x (Baseline) |

| Mild Steel | 120-200 | 100-300 | Medium | 2.5-3x |

| Tool Steel | 300+ | 70-150 | High | 4-5x |

This translates directly to production efficiency. When we machined identical components from aluminum versus steel for a recent automotive client, the aluminum parts were completed in just 38% of the time required for steel, with significantly less tool replacement. For time-sensitive projects or when minimizing labor costs is essential, this difference cannot be overstated.

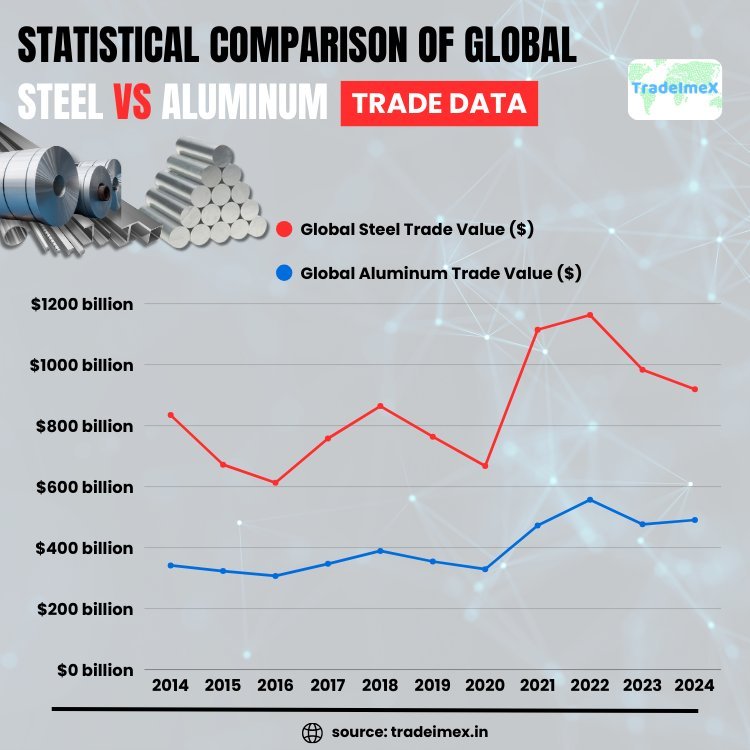

What Factors Should You Consider When Deciding Between Aluminum and Steel?

Last year, I made the wrong material choice for a client's vacuum chamber fixtures and had to remake everything. The project taught me that expected part volume and application requirements must drive material selection.

Consider production volume, application environment, and budget constraints. For runs under 10,000 parts, aluminum tooling often delivers better ROI. For high-volume production exceeding 50,000 parts, steel's durability typically justifies its higher initial cost through longer tool life and consistent precision.

Decision Flowchart for Material Selection

Making the right material choice requires balancing multiple factors against your specific manufacturing goals. Based on our experience producing components for industries ranging from medical devices to aerospace, here are the critical considerations:

Production Volume and Tool Longevity

The expected production volume significantly influences material selection. I've analyzed hundreds of production runs and found clear threshold patterns:

| Production Volume | Recommended Material | Justification |

|---|---|---|

| Prototyping (<100 units) | Aluminum | 40-60% cost savings, 60-70% faster production time |

| Low Volume (100-10,000) | Aluminum | Good balance of cost/durability, faster iteration |

| Medium Volume (10,000-50,000) | Depends on application | Analysis needed: temperature, stress, precision requirements |

| High Volume (>50,000) | Steel | Lower cost per part over time, maintains precision longer |

One automotive client initially requested aluminum tooling for a high-volume dashboard component. After discussing their 100,000-unit production forecast, we recommended steel instead. While the initial tooling cost was 70% higher, the steel tooling maintained dimensional stability throughout the production run, while aluminum would have required at least two replacement tools, resulting in a 15% overall project savings.

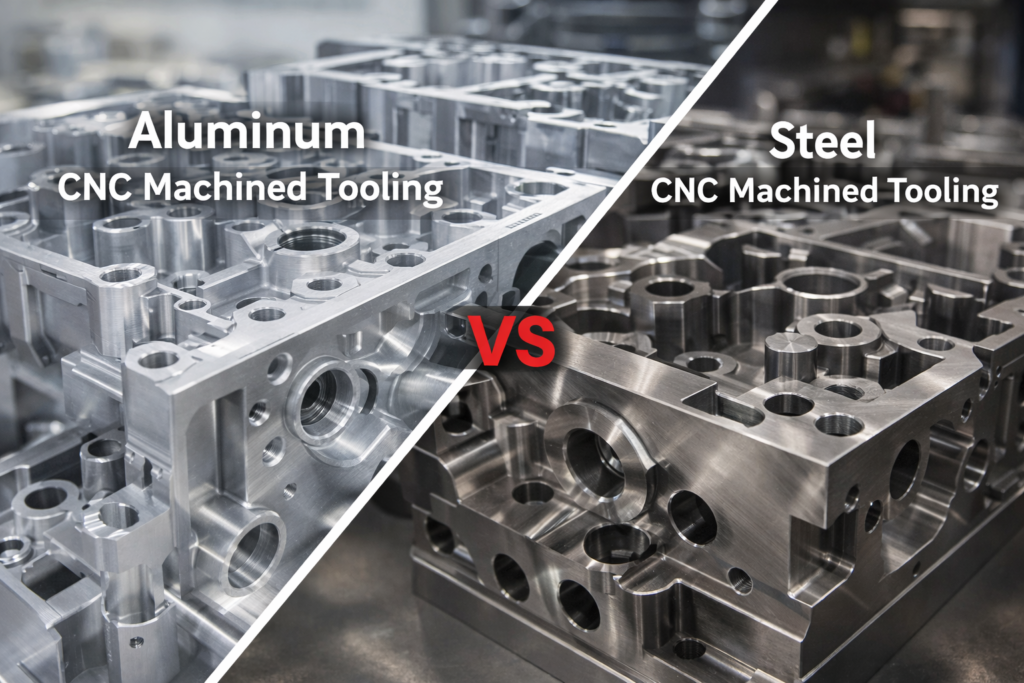

Why Are More Manufacturers Reconsidering Traditional Material Choices?

Traditional thinking defaulted to steel for nearly everything, but I've witnessed a paradigm shift. Modern manufacturing demands have pushed more of our clients to reconsider aluminum for its speed and cost advantages.

Advanced aluminum alloys now offer improved strength and wear characteristics while maintaining processing advantages. Companies focused on rapid iteration, just-in-time manufacturing, and lean principles increasingly choose aluminum tooling to reduce lead times by 50-70% and improve cash flow with lower upfront investments.

Modern Manufacturing with Aluminum Tooling

The manufacturing landscape has evolved significantly in recent years, challenging traditional material selection practices. Several factors are driving this reconsideration:

Economic Pressures and Production Timeline Compression

Market demands have fundamentally changed production economics. Today's competitive environment requires:

- Faster Time-to-Market: Product development cycles have compressed by approximately 30% over the last decade

- Capital Efficiency: Companies are increasingly unwilling to tie up capital in expensive tooling that may become obsolete

- Design Iteration: Products evolve more rapidly, requiring tooling that can be modified quickly and economically

These pressures have led to creative material usage strategies. For a recent medical device client, we implemented a hybrid approach—using aluminum tooling for initial production while steel tooling was being fabricated concurrently. This allowed them to begin selling products 3 weeks earlier than traditional sequential tooling would have permitted.

The cost analysis has become more sophisticated as well. Modern manufacturers now consider not just the direct material and machining costs, but also:

- Opportunity cost of delayed market entry

- Cash flow implications of tooling investment

- Lifecycle cost, including potential design changes

- Environmental impact and sustainability factors

This comprehensive approach has revealed that in many cases, the traditional default to steel tooling was based on outdated assumptions rather than data-driven analysis.

Conclusion

Choose aluminum for faster production and lower costs in low-volume applications. Select steel when durability and precision over high volumes justify the higher initial investment. Analyze your specific needs carefully—the right material choice will optimize both your production efficiency and bottom line.