Many small and medium-sized manufacturers operate in local markets where they lack the scale and capital to significantly impact their potential market share. In this scenario, they cannot compete against larger companies on product effectiveness. Usually, they are forced to resort to low-cost practices and lower-quality products to retain their customers and attract new ones.

However, there is a way for them to compete with larger companies. They can utilize the multimillion-dollar precision machining market to minimize their production cost and get their business back on track. The industry can be explained as the manufacturing process of molding, toolmaking, and precision cutting. This article will discuss its benefits and factors to look up to when involved in precision machining. Let's get started.

What is Precision Machining?

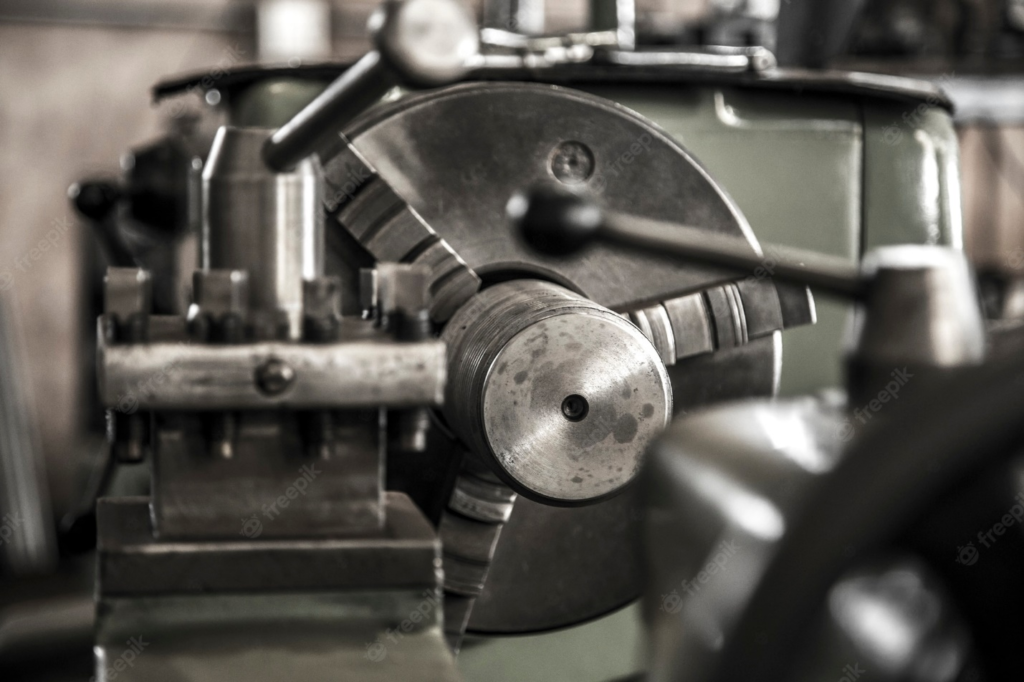

Precision machining is a manufacturing process that relies on computer numerical control to produce parts with tolerances of up to millionths of an inch. The components are produced to a high degree of accuracy, using various tools and techniques. It uses machine tools equipped with computer numerical control (CNC) equipment to make parts that other traditional machines cannot. As a complex machine, the CNC machine's primary function is to aid in manufacturing different components.

It could involve metalworking or manufacturing, typically done in an industrial environment. In modern computer numerical control (CNC), lathes and milling machines are sometimes called precision machines or CMM. Precision machining is more precise than traditional, where tolerances only need to be in the thousands. Precision machining can achieve tolerance levels of 1/1000th of an inch.

Benefits of Precision Machining Companies

Precision machining companies have been around for a long time. The first precision machining company was set up in 1775 by John Wilkinson. Since then, the industry has grown exponentially, and now there are more than 100,000 machining companies in the U.S. alone. Here are some of the benefits of Precision machining companies.

- Quick turnaround. Making a product using these machines is very quick compared to other methods used by other companies. So, if you want your product delivered quickly, this is the right option. Precision machining companies have developed numerous innovative ways to make items easier to produce.

- Low error. The companies have a high level of accuracy, which results in a low error rate. Your product will be free from any defects and errors. Also, these machines can produce several products simultaneously without compromising on quality or precision. You can get a product with exact measurements every time from these companies with no extra effort on your part.

- Affordable pricing. The most impressive benefit of the quality control method of manufacturing is its affordability. You can hire precision machining companies to create the parts you need for your company at a fraction of what you would pay to outsource similar parts. Precision machining companies charge less than other methods used by other companies, such as milling and turning, etc. It makes them affordable for everyone who wants their products completed in bulk without compromising quality.

- It has reduced labor costs. When you have many products that need to be machined, it takes time for workers to complete them all. It slows down your production time, but you must pay your workers for more hours. One worker can operate several machines at once when using a precision machine. You don't have to hire as many employees or pay them overtime.

- Increased efficiency. It's more efficient to outsource the work to a company that does precision machining for a living. Your employees don't have to spend their time working on manufacturing your products; they can focus on their core areas instead. You might find that eliminating non-core tasks also saves you money on training and education.

- Minimizes material waste. A precision machining company will use as little material as possible to create your part. They'll also make the part as close to its final size as possible without resizing it later in the manufacturing process, minimizing material waste further.

What to Consider when Choosing a Great Precision Machining Company

1. Location

Finding a precision machining company can be overwhelming, especially if you're a business owner who doesn't have the time to do extensive research. It would help if you had someone close to your area with plenty of experience and attention to detail. Most precision machine shops are usually located in industrial sections of a city due to the noise levels and requirements for space.

It would be best if you tried to identify a company that has been in business for an extended period. Make sure that they have adequate space to handle your project. A smaller company might be ideal for simple tasks such as cutting or drilling out small holes. However, if you need complex precision parts made from rugged materials, you will probably need a larger manufacturing facility.

2. Price

Precision machining companies charge very high prices considering their quality of work and other factors. An ideal component of precision machinery is its accuracy. You need to evaluate the situation and determine whether your product requires extreme accuracy for the job.

A precision machining company will cost you more than a job shop-based operation and less than a factory. The number of machining operations and the complexity of those operations will all influence the price of any project. Thus, it is vital to understand the capabilities of the precision machining company you are considering before you get started on your project.

3. Design skill

The design skill of the company you choose is an essential factor in creating parts that you need for your project. Many facets go into making these parts, and if the company's design skills are not up to par, your details will be lacking.

You want to be sure that you hire someone capable of engineering and designing your parts. If they don't have this skill set, it will limit what they can do for you, and they'll have to outsource these services somewhere else anyway.

4. Communication

Communication is critical in any business, especially when working with clients. The company should be able to clearly explain the process and answer any questions you may have along the way. If they cannot do this or seem disinterested in your project, you may want to look elsewhere for someone who can help with your needs.

You want to communicate clearly with them so that they understand precisely what you want to be done and how you want it done. It's crucial if you have an idea for a new product or an existing product that needs improving. You should get feedback from them on your project to complete it on time and within budget constraints.

5. Knowledge

A good precision machining company should know enough about the products and services. They should know how to use different tools for precise measurements, cutting, drilling, and other processes involved in making intricate parts for various industries.

They also need to understand what materials would be best suited for each project. They should also have excellent customer service skills to assist if you have any questions or concerns regarding your order.

6. Technology and materials

Looking for a company that has been in the market for a long time will have accumulated the experience required to identify what technology is best suited for your needs. You will get the best quality products at the end of the day. The materials used should also be considered. You want to find a company that uses only high-quality materials to avoid dealing with products that will not last if you want them to.

7. Experience

A good company has built its reputation by providing excellent services over time and building relationships with its clients. An inexperienced company may not have enough experience or knowledge to complete all aspects of your project.

It would be best if you looked for companies that have been around for at least five years and preferably longer than that. You want to know how customers feel about working with this company before signing any contracts or paying them any upfront money.

8. The type of precision machining

There are many different types of precision machining companies out there, so it can be hard to choose the right one. The kind of precision machining that you want will determine what type of company you want to work with. For example, working with a small precision machining company may not be ideal for your needs if you wish to do high-volume manufacturing.

If you want low-volume manufacturing or prototyping, working with a larger company may be more appropriate than a smaller one. Ensure that the type of manufacturing you need matches the manufacturer you are looking to work with.

9. Lead Time

Lead time is the time it takes for an order to be completed from when you first submitted it. It usually depends on how busy the company is and how much work they already have on their hands.

You need to know how long it will take them to manufacture your product before they start working on it. Remember that precision machining takes time because it involves machines that work slowly and carefully. Also, you need to choose a company that can deliver your product on time, especially if you have an urgent order.

10. Certifications

Ensure that the company you choose has the experience and the know-how to get your job done right. A certified precision machining company will have proof that they have been trained in various areas and have the skills to do the job. If a company does not have proof of certification, this could indicate difficulty or even problems with its quality.

You need to ensure the company provides quality products. Certification is an indication that the company offers quality products and services. To be certified, it must meet all the requirements of international standards.

What are the Main Types of Precision Machining?

With such an extensive range of precision machining methods, it can be challenging to know which one is best for your production. Below are some of the most common types of precision machining and what they are used for.

- Lathe Machining. It's a technique where a rotating workpiece is fed past a stationary cutting tool to create cylindrical parts. You can use the method to create components with complex external geometries that would be difficult or impossible with other processes.

- Milling Machining. A milling machine rotates a tool with multiple cutting edges against the surface of a workpiece. The device is fed into the workpiece at varying angles and depths to remove material gradually. The technique is commonly used for making complex, three-dimensional shapes such as turbine blades and engine manifolds.

What is the Precision Machining Process?

Precision machining is the process of creating a part that meets strict specifications. A piece can be made as a one-off item, a small batch of hundreds or thousands, or a large volume, such as millions of components for a consumer goods product. The process involves cutting away excess material from a block of raw material, then finishing it by grinding and polishing the surface. It leaves a finished product that meets tight tolerances, often down to +/- 0.001 inches or better.

The main tools used in this process include lathes, grinders, and mills. A computer-aided design software (CAD) and computer-aided manufacturing software (CAM) control the tools. The tools themselves can be computer-controlled or manually operated. The step is relatively new compared to the rest of the process because it wasn't until recently that computers could quickly read and translate data.

The CAD/CAM software uses a complex algorithm to run through millions of calculations per second. A wide range of materials can be cut and finished, including steel alloys, stainless steel, copper and aluminum alloys, tungsten carbide, and plastics.

Conclusion

When researching potential precision machining companies, focus on a few key factors. Don't settle for anything less than the factors discussed above. It's crucial to find a precision machining company that is a good fit for your needs, and those that can offer all these characteristics are worth the extra research.

If your business is turning to machine shops for precision machining, you must have a precise vision of what you require. After extensive research, you should only vet the manufacturing facilities you choose to work with. It means that you should get as much information as possible before making any decisions.