To adapt to the current advancements, firms have developed a lot of indigenous techniques for the development of mask machine cutters. In this article, I’ll take you through the different types of mask machine cutters and mask machines. You can take it as a guide because it would definitely help you in choosing the right cutter for your mask machine.

N95 Mask Machines:

The use of N95 masks emerged as the increase in particulate matter in the outside world increased. This resulted in a lot of stress on the mask machine market and for this purpose, business for the CNC parts of mask machine increased.

N95 mask machines available in the market are of different types considering their applications in the modern world. The main two types of N95 mask machines are:

Fully Automatic N95 Mask Making Machine:

The fully automatic variants of mask making machines have been in the market for a long time now. With advancements in features, these machines have been subjected to a lot of innovations. These innovations include the CNC parts for mask machines that have been developed using the techniques for better precision and accuracy. Fully automated N95 mask making machines include the various systems and processes that are controlled numerically.

This indigenous machine is the answer to all the problems regarding the shortage of face masks because the operating speed of this machine has no match. With these high-tech CNC controller-based machines, you are able to easily produce around 1-200 pieces per minute. Now that is a major plus-point for this machine especially because it is specially designed for approved N95 masks.

Semi-Automatic N95 Mask Making Machine:

This is rather an older version of the mask making machine. This machine uses a very limited amount of automation for its processing and is generally utilized in smaller industries and startups. The automation part in this machine is on the material feeding portion where the automated roller inputs the masks into the machine that force it for further processing. You’d find these machines quite easily available on the market but these machines have a rather low production rate.

Apart from the material feeding portion, these machines also have an automated ultrasonic welding arrangement. This arrangement can be automated in these machines and this is a plus point for these machines. The placement and branding process might be different from that of the fully automatic machines which is why it has a low production rate.

Comparison between Automatic and Semi-automatic N95 Mask Making Machine:

The comparison between the two types of machines has been quite significant. You wouldn’t be amazed to find out that fully automatic N95 Mask Making Machines have the edge over the Semi-Automatic ones due to their proper applications and ability to produce at a much higher pace. The fully automatic mask machine can directly produce finished masks, while the masks processed by semi-automatic mask machines need other auxiliary equipment to complete the unfinished parts, so that they can be a complete mask. You can see a very basic comparison of the two types of machines below:

| Semi-Automatic N95 Mask Making Machine | Fully Automatic N95 Mask Making Machine |

| Cheaper than Automatic | Cost is higher as compared to conventional |

| Required low maintenance | Requires higher maintenance |

| Slow Processing / Production Rate | Fast Processing / Production Rate |

| Limited Applications | Multiple Applications |

| Good for Small Startups | Can be used on a large scale |

Production Process for N95 Mask:

To manufacture a mask, it is quite important to know about the performance of various processes. Generally, mask making is considered to be quite simple considering the simplicity of the design, but the room for optimization still needs to be fulfilled. This can be done using the proper tools required for mass production.

Reference: https://www.onlineclothingstudy.com/2020/04/face-mask-manufacturing-machines-and.html

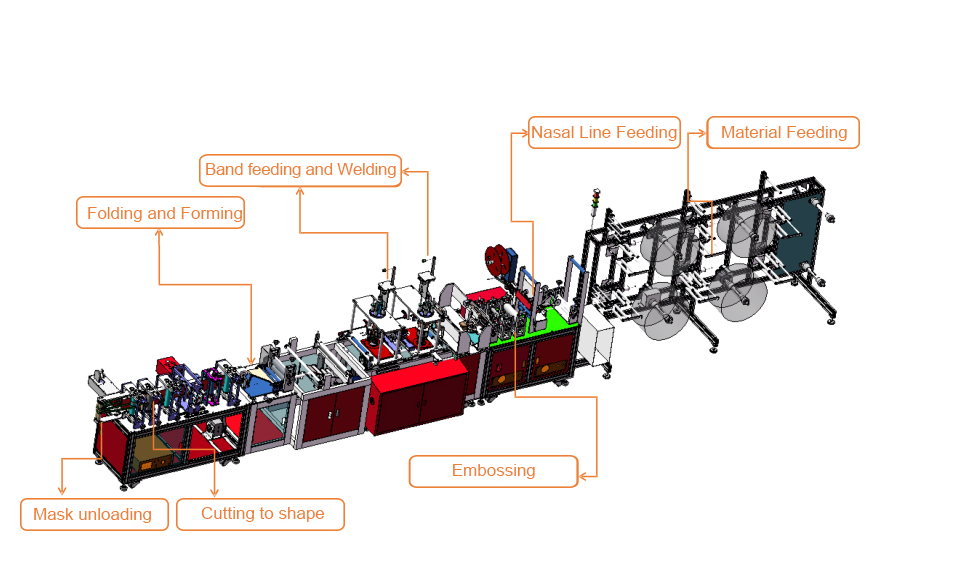

For N95 masks, there are certain processes that take place but the most important of them all is the part where the machine cutter needs to be used. China mask machining utilizes these machine cutters for the better form and shape of N95 masks. Let's have a look at a fully automated mask machine you’d find in the market and how many sub-machines are in it:

Coil Material Feeding:

This is the part where most of the material used in the face masks is supplied to the machine. It utilizes the already available system of conveyors and directors to carry out the process of feeding the face masks.

Nose Bridge Tendon Feeding:

This is where the nose bridge tendon is inserted into the mask. When you wear a mask, there is this metal wire or simple thin plate that is present at your nose bridge. To wear it properly, you push it down so the mask sits on your face. That is what a nose bridge tendon is!

Folding and Pressing:

The crux of the whole process is based on this step as it is the most crucial part. Precise folding and pressing which is so satisfying to watch that you’d be willing to watch it all day long. Don’t be surprised if you see this folding and pressing process pop up in your stream of satisfying TikTok videos.

Band Feeding and Welding:

Bands of polyester that are for the ears are then inserted into the folded masks which are then welded either by conventional heating or through ultrasonic waves. Melting the polyester onto the mask fabric to join them together more or less completes the whole process.

Cutting Process:

This is by far the most important part of the whole process because this is where the machine cutter performs the cutting process. Specialized CNC mask machine cutters are used for the rapid cutting of the material.

Reference: https://www.saintytec.com/surgical-mask-making-machine/

What is N95 Roller Die?

Roller dies are used in many conventional machines. As the name implies, there are a lot of different applications for roller dies and these can best be described by their use in forming or shaping industries. In mask machine machining parts, the most important is the roller die or in simple terms, it is the mask machine cutter. It consists of a simple roller made of steel or other tool material utilized for the forming and cutting of the CNC mask. With the automation process supporting the cutting, it helps in the rapid production of N95 masks with minimal uncertainties.

Material of Roller Dies:

So you might be wondering what type of materials does these roller dies use? Well, it’s pretty simple because tools generally need sharpness and the right amount of material properties for their better functioning. Imperatively, most mask face cutter machinery uses DC53 Machine Tool material with a hardness of HRC58-62.

These tools are specialized based on the applications and are able to carry through a large number of cutting processes during mask making. Operation of these tools are quite simple and they can be handled according to the requirements.

N95 mask cutting roller:

The cutting roller is made of DC53 with a hardness of HRC58-62, which is used for mask shape cutting. Processed by the vacuum quenching, which ensures homogenization treatment, so the roller will last much longer.

N95 Edge Sealing Die:

Another roller die that is normally used is the edge sealing die that helps in sealing the multiple layers of the mask material. These are hot rolled and need to have a lot of weight because of the application they are serving. So these are made from Cr12mov with a hardness of HRC58-62. With these specifications, it is rather easy to seal the edge of the N95 mask because of the material they are made of.

N95 Mask Embossing Roller:

This roller allows you to easily emboss the brand name of the mask or the logo reading the N95 mask. This is rather quite similar to the edge sealing die as it serves almost the same purpose. Owing to this, it is made of the same material for the edge sealing die. The embossing roller has high hardness and good wear resistance.

Reference: https://www.mecholic.com/2016/02/different-types-of-cutting-tools-materials-and-their-properties.html

How do I buy the best quality Mask Machine Cutter for my Machine?

Now, here is the most important part of this article. Machine cutters are available in multiple shapes and forms with their own perks and benefits. Each cutter has its own distinct characteristic that is utilized according to the application.

Distinguishing the Cost Performance:

Generally, it is perceived that there are certain aspects relative to the performance of machine cutters. Except for the multiple aspects, there are significant differences in terms of the cost performance as well. Going into the market, you’ll get many KN 95 face mask machine quotes relative to your application but not all of them would suit the purpose. To properly select a machine cutter, you must try to optimize your decision both by the cost and through the tool life as well. There are mainly four aspects that you must take into consideration when making a choice for mask face cutter machinery, they are:

- Average Price

- Match Quality

- Lead Time

- Inspection of Goods

Average Price:

Now let's have a look at what the average price of the CNC parts of the mask machine looks like. These would help you get an idea about the situation of the market when making the choice for the machine cutter. The price really depends on what you are dealing with, either you are interested in a fully automatic or semi-automatic roller die.

N95 roller dies are different in both cases of the machine due to their applications in terms of the making process. So for a semi-automatic N95 roller die you must keep in mind that it would cost you around $1500 but the deal breaker is the application and its efficiency. These roller dies have a lesser capability to adapt to the different production requirements due to their lesser performance.

On the other hand, if you’re looking to buy a fully automatic N95 roller die then the cost would increase by 25% and it would be almost $2000 that is a bit costly. But as I mentioned earlier during the comparison of the two, this roller would be quite handy in producing multiple masks at a rapid pace.

So, apart from this, if you’re looking to get your own design then the price would increase as well. The price could very well increase by 30% or even more depending upon your design. Therefore, just as a rough idea, the cost is likely to increase by $300 to $500.

Match Quality:

The next thing you must know is that the match quality for the cutter needs to be optimized. By match quality, it means that the production rate and the longevity of the mask cutter need to be kept in mind. Considering the rate of production, you must understand that in general the output of the semi-automatic N95 mask machine cutter is 30-50 pieces per minute running at an optimized pace. This would mean that it would be giving you about 57,600 pieces per day.

Now to check for the machine cutter to be running perfectly, you need to make sure that the cutter is cutting perfectly. In an event that the cutter misses out on cutting, you must know that it needs to be replaced. Normally, that doesn’t happen really quickly, but if you’re running the machine for 2 to 3 days continuously without any breaks then the story is quite different.

Lead Time:

Additionally, you should also keep lead time in mind because normally this is what delays most of the processes going on. Upon ordering the machine cutter, you need to wait for a certain time until your cutter is ready to be processed. If the cutter is in stock then it would take only two days for packaging and customs declaration document.

On the other hand, if the cutter is out of stock then it would test your patience because it would take some time for the OEM to manufacture the proper tool you need. Two days for purchasing raw materials, five days for rough machining, two days for heat treatment, five days for finish machining, two days for chip removing, one day for quality testing. The lead time is 15-20 days.

Inspection of Goods:

The next thing you should know is to check for any background of the vendor so it can be certified if he is a proper vendor or not. Generally, a random mistake is often made regarding the overall maintenance and support for the supplied products. There are some factors you need to learn when surveying the market for machine cutters. Some factors are:

First of all, before purchasing you must make sure that there is technical support available for your machine cutter because lapses in installation could occur.

Before shipping, you need to make certain that the measurements for the shafts are according to your requirements because then you might need to send it back for replacement. This would cause delays.

Finally, after receiving the goods, ensure that the cutter isn’t used and does not have a lot of wear on it because used cutters have a lesser life.

Conclusion:

So in conclusion, fully automatic N95 mask making machine has high automation level, which is now fully automated from raw material feeding, nasal line feeding, embossing, band welding, folding and forming, mask cutting, finished mask to waste material removing. Only one person are needed for its operation, which realize high efficient face mask production.