In the world of engineering, choosing the right material can make or break the success of a project. Sometimes, the perfect choice isn’t metal or a traditional plastic; it’s something a bit more unconventional yet incredibly effective. That’s where Vesconite comes in.

If you’ve ever dealt with harsh industrial environments, constant maintenance headaches, or materials that just don’t hold up under pressure, you’ll know the struggle. Vesconite changes the game, offering a combination of strength, durability, and low maintenance that’s hard to beat.

In this guide, I’ll walk you through everything you need to know about Vesconite: what it is, why it’s unique, where it’s used, and how it stacks up against other materials you might be familiar with. Whether you’re an engineer, a designer, or someone simply curious about smarter material choices, there’s a lot to uncover.

What Exactly is Vesconite?

When we think about the toughest, most unforgiving environments, mining sites, deep-sea vessels, and railway systems, materials are pushed to their limits. Metals corrode, plastics swell or degrade, and maintenance costs pile up. This is exactly the kind of challenge that led to the creation of Vesconite.

In simple terms, Vesconite is a hard-wearing, self-lubricating thermopolymer. It’s engineered to handle extreme conditions where traditional materials often fall short. Imagine a material tough enough to replace bronze in bushings and bearings yet slick enough to reduce the need for constant greasing. That’s Vesconite in a nutshell.

But where did it come from?

The story of Vesconite begins in the rugged industrial landscape of South Africa. During the 1960s, local industries, especially mining, were grappling with enormous challenges. Conventional materials like bronze were corroding quickly under harsh, dirty, and wet conditions. The need for something stronger and more resilient became urgent. That's when Dr. Jean-Dirk Uys, a South African engineer, developed Vesconite. His goal was clear: create a polymer that could survive these brutal environments without succumbing to wear, corrosion, or high maintenance costs.

What makes Vesconite different from other plastics like nylon or PTFE (Teflon)? It’s all about the chemistry. Vesconite is a proprietary blend designed for maximum durability and stability. Unlike nylon, Vesconite doesn’t swell or absorb moisture, a major advantage in humid or submerged conditions. And while PTFE is famous for its slipperiness, it can be too soft for heavy-duty applications. Vesconite strikes a perfect balance: it offers low friction without sacrificing strength.

Compared to metals like bronze, Vesconite is lighter, corrosion-resistant, and self-lubricating, meaning it can operate longer without the need for grease or oil. Compared to other plastics, it stays dimensionally stable even when exposed to water, heat, or harsh chemicals.

At its core, Vesconite isn’t just a better plastic; it’s a smarter material choice. It combines the best properties of metals and polymers, giving engineers a real alternative when traditional options fall short.

Types of Vesconite Materials

One of the reasons Vesconite has earned such a loyal following is that it’s not a one-size-fits-all material. Over the years, the original formula has evolved into a range of specialized versions, each designed to meet different industry needs. Let’s break down the main types of Vesconite and what makes each one stand out.

Vesconite Standard

First up is the classic Vesconite Standard. This is the original material that started it all. It’s known for its high load-bearing capacity, excellent wear resistance, and low friction properties. Vesconite Standard shines in applications where you need a tough, dependable material that won’t swell or degrade under pressure.

Commonly used in:

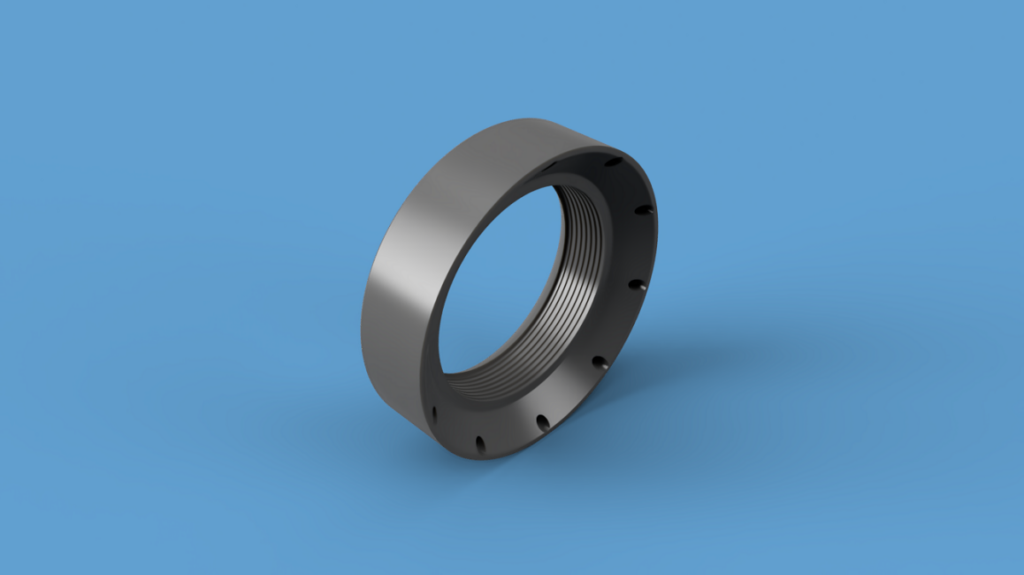

- Bushings and bearings

- Wear plates

- Industrial machinery components

- Agricultural equipment

It’s the reliable workhorse of the Vesconite family, perfect for general-purpose applications where conditions are tough but not extreme.

Vesconite Hilube

Next, we have Vesconite Hilube, the “next-gen” version. Think of it as Vesconite Standard but supercharged for even tougher, faster, and more demanding applications. Hilube has an even lower coefficient of friction, which means it performs better at higher speeds and under lower lubrication conditions.

Key features include:

- Ultra-low friction for smoother operation

- Higher wear resistance compared to the Standard

- Improved dimensional stability, even in wet environments

Where does Hilube really shine? It’s widely used in industries like:

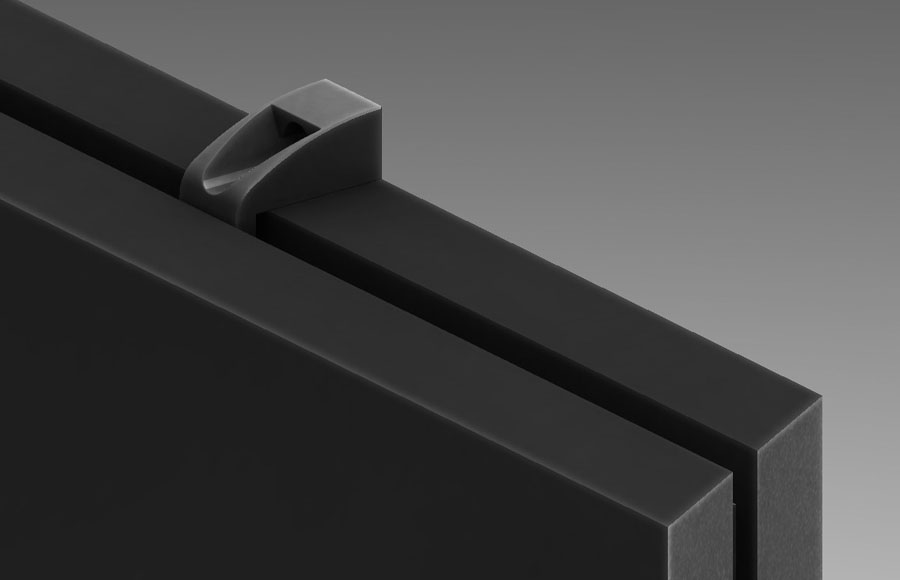

- Marine: Rudder bearings, stern tube bushings

- Rail: Side bearers, center liners

- Mining and industrial: Where high speed and load come into play

If you’re working with submerged components or fast-moving machinery, Hilube is often the smart upgrade.

Vesconite Superlube

For the most demanding environments, there’s Vesconite Superlube. As the name suggests, it’s all about ultra-low friction and extreme performance. Superlube is engineered for specialized, high-performance uses where even minimal lubrication is difficult or impossible.

Key features include:

- Extremely low friction, perfect for dry running

- High-temperature resistance

- Enhanced chemical resistance

While Superlube isn’t needed for every application, it’s a lifesaver in niche areas like:

- High-speed rail components

- Heavy-duty marine equipment

- Precision industrial machinery

It’s not just an improvement; it’s a game changer for certain industries.

Quick Comparison: Vesconite Types

| Feature | Vesconite Standard | Vesconite Hilube | Vesconite Superlube |

| Friction Level | Low | Lower | Ultra-Low |

| Wear Resistance | Excellent | Higher | Highest |

| Best For | General Industrial, Agriculture | Marine, Rail, High-speed Applications | Specialized High-performance Areas |

| Water Stability | High | Higher | Very High |

| Lubrication Need | Minimal | Minimal to None | Practically None |

| Temperature Tolerance | Good | Better | Best |

Choosing the Right Vesconite for Your Needs

So, which one should you pick? Here’s a quick guide:

- For general heavy-duty applications where durability is key, Vesconite Standard does the job perfectly.

- If you're dealing with high-speed machinery or underwater environments, Vesconite Hilube is your go-to.

- And if you're in a specialized field with high-precision, high-speed, or extreme conditions, Vesconite Superlube can give you the performance edge you need.

Choosing the right material isn’t just about specs; it’s about matching the material to the real-world demands of your project. Vesconite gives you that flexibility.

Key Advantages of Vesconite

It’s one thing to say a material is “game-changing”; it’s another to back it up with real, tangible advantages. Vesconite isn’t just popular because it’s different; it’s trusted because it consistently delivers where other materials fall short.

Here’s what really sets Vesconite apart:

High Wear Resistance

One of Vesconite’s standout features is its exceptional wear resistance. In tough industrial settings where equipment runs for long hours, wear and tear can quickly become a nightmare. Vesconite shrugs off abrasion and friction in a way few materials can. Bearings and bushings made from Vesconite simply last longer, meaning fewer shutdowns, fewer replacements, and less maintenance overall.

Low Friction Coefficient

Here’s where things get interesting: Vesconite is self-lubricating. That means it has an impressively low friction coefficient, even without external lubrication. In practical terms, machinery runs smoother, components heat up less, and you save on grease, oil, and maintenance time. Especially in industries where lubrication is tricky, like underwater marine components, this low friction gives Vesconite a major edge.

Dimensional Stability in Wet and Dry Conditions

Traditional plastics like nylon can absorb moisture and swell, which is not exactly ideal if your equipment is exposed to water or humidity. Vesconite, however, is dimensionally stable whether it’s bone dry or fully submerged. It doesn’t absorb water, meaning no swelling, no warping, and no surprises during operation. This stability makes it a favorite for marine and agricultural industries, where exposure to the elements is a given.

Load-Bearing Capabilities

Despite being a polymer, Vesconite has load-bearing capacities that rival metals like bronze. It can handle high compressive loads without deforming, which is critical for applications like bushings, wear plates, and bearings. This makes it not just a lightweight substitute but a serious upgrade in heavy-duty settings.

Temperature Resistance

While many plastics lose their strength at elevated temperatures, Vesconite is designed to withstand moderate to high temperatures without significant degradation. Whether you’re operating in the scorching heat of a mine or the friction-heavy environment of a railway system, Vesconite keeps its cool, literally and figuratively.

Corrosion and Chemical Resistance

If you’re working in corrosive environments, think salty seawater, harsh chemicals, or contaminated industrial sites, Vesconite’s corrosion resistance is a lifesaver. Unlike metals that rust and degrade over time, Vesconite remains stable and strong, even after long exposure. It’s also resistant to many chemicals that would destroy other plastics or metals.

Real-World Example: Vesconite in Action

To really drive this home, let’s look at a real-world case study.

A mining company in South Africa, operating under brutal, dusty, and wet conditions, was struggling with bronze bearings on its equipment. Constant exposure to mud and grit meant frequent bearing failures, leading to expensive downtime and sky-high maintenance costs.

After switching to Vesconite bushings, the results were dramatic:

- Bearing lifespan tripled

- Maintenance intervals doubled

- Overall operating costs dropped by nearly 30%

The best part? Operators reported smoother equipment operation and less downtime, a massive win for productivity and profitability.

The next section will delve deeper into the characteristics of this material through several case studies and will introduce its applications in different industries.