As I embark on my day, I can't help but notice the huge impact that machining has on the personal items and gadgets that we carry with us. By being with me all day and improving my daily experiences, these gadgets have developed into an addition to my identity. The tremendous impact of Computer Numerical Control (CNC) machining on these commonplace companions is intriguing to investigate when one delves into the realm of production. The accuracy required in the manufacture of smart personal accessories like smartphones, earbuds, and other devices is a tribute to the amazing potential of CNC technology.

Let's begin by looking at how CNC machining affects cellphones, which have grown to be an essential part of our life. I am intrigued by the gorgeous design and the skill with which it has been built when I hold my svelte smartphone in my palm. Using CNC machining, which enables the production of complex components that contribute to the device's svelte appearance and faultless performance, is essential to the manufacturing process.

Smartphone (source)

The accuracy with which the outside of the smartphone is fashioned is the first feature that sticks out. Blocks of materials like aluminum or stainless steel are painstakingly carved out by CNC machines to create the phone's frame, resulting in svelte and seamless designs. An aesthetically pleasing item that fits naturally in my palm is the consequence of the carefully machined and carved curves and edges. The finely crafted finishes and complex details made possible by CNC machining add to the smartphone's overall premium appearance.

Beyond the outside, CNC machining is essential in the production of the parts that make up cellphones' internals. Camera modules, processors, and connections are just a few of the delicate components that are painstakingly created utilizing CNC technology to power these gadgets. Since these parts fit together perfectly thanks to CNC machining's precision and repeatability, the gadget will function perfectly. With the use of CNC machining, producers can now attain a degree of accuracy that was previously unthinkable, whether it be the exact alignment of the camera lens or the complex circuitry within the processor.

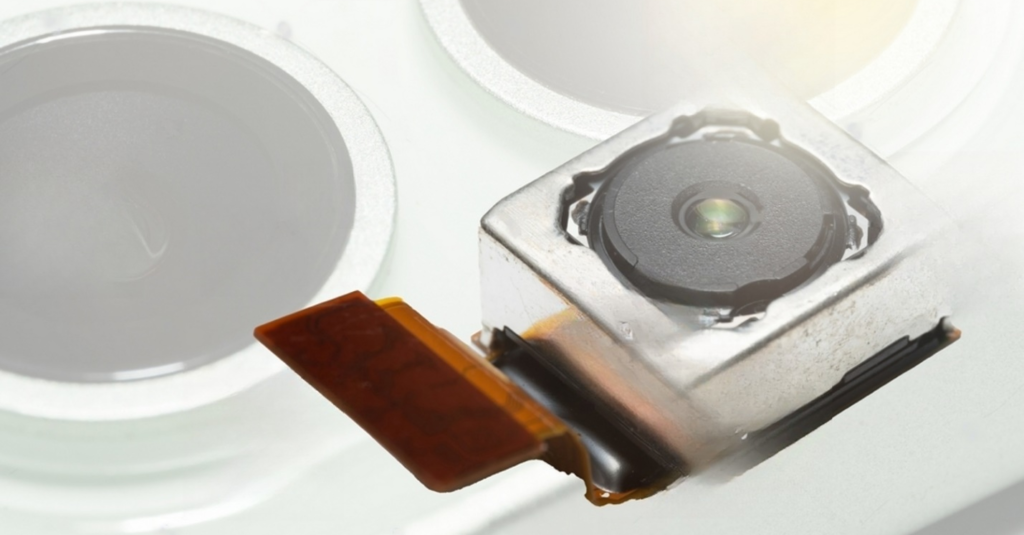

camera module (source)

The ability to take beautiful photos and films is made possible by camera modules, which are a crucial aspect of contemporary smartphones. These modules are made up of complicated lens assemblies, image sensors, and other parts that are all closely integrated in a small area. The production of these camera modules with the highest level of accuracy and precision relies heavily on CNC machining.

Watches

I am fascinated to the world of watches as I continue to research the precise production procedures that form the things we use on a daily basis. Watches are more than simply timepieces; they are wonderful works of art that exemplify accuracy and artistry. In this voyage, I explore into the making of watches, with an emphasis on the minute and hour hands, the metallic watch band with its complicated connections, the watch shell, and the little gear movements within. Through this investigation, I want to demonstrate the level of accuracy necessary for elaborate patterns and working mechanisms while inspiring readers to consider their own possessions and see the seamless relationship between CNC technology and self-expression.

A wrist watch (source)

I'm most fascinated by the tiny, delicate gear systems seen in timepieces. A symphony of gears, springs, and diamonds collaborate in harmony within the watch's small shell to keep time running smoothly. The competence and accuracy of machinists are shown by the production process of these complex devices. The most precise manufacturing of these gears is made possible thanks in large part to CNC (Computer Numerical Control) technology. The detailed blueprints that govern the constant action of the CNC machines cut out each gear tooth precisely, guaranteeing a tight fit that ensures the clock will run without interruption.

watch's movement mechanism (source)

The watch case itself is a piece of beauty in addition to the complex mechanisms. The case is skillfully crafted from materials ranging from stainless steel to priceless metals like gold or platinum to safeguard the sensitive inner workings and lend a touch of beauty to the overall look. In order to form the casing and guarantee a proper fit for the mechanical components, machining techniques including milling, turning, and drilling are used. The use of CNC technology enables the production of complicated forms and detailed patterns that were previously thought to be unachievable. The case of a watch reflects the personality and sense of style of the person wearing it, whether via painstakingly carved designs or unusual mixes of brushed and polished surfaces.

Another example of fine engineering is the metallic watch strap with its complex links. The watch band, which was made to be both useful and visually beautiful, goes well with the watch's overall style. Each every link is painstakingly made and carefully put together to provide a snug and secure fit on the wrist. The structuring of these links using CNC technology is essential for producing flawless connections that increase the watch's sturdiness and attractiveness.

metal watch band (source)

My focus is pulled to the minute and hour hands as I study the watch display. To guarantee precise timekeeping, these thin, precisely balanced timepieces have been carefully manufactured. The hands must be carved, shaped, and polished throughout the production process to attain the correct proportions and appearance. The hour hand follows the minute hand at a controlled speed while the minute hand, which is slightly longer than the hour hand, elegantly round the dial. It is astounding how much accuracy was needed to create these hands. The accuracy of the clock may be affected by even the smallest change in length or weight distribution.

I can't help but make comparisons between our own lives and the treasured items we possess when I think about the complex manufacturing procedures that give timepieces life. We are surrounded by commonplace products that have undergone comparable production processes. CNC technology serves as the foundation for seamless self-expression in everything from our smartphones' svelte exterior to their sophisticated interiors, camera modules, and metallic watch bands with connections.