- sales92@partstailor.com

- +86-18551199566

20 Years of Expert Manufacturing | Complete Type II & Type III Anodizing Services | Six Standard Colors & Custom Options | Strict Compliance with International Quality Standards

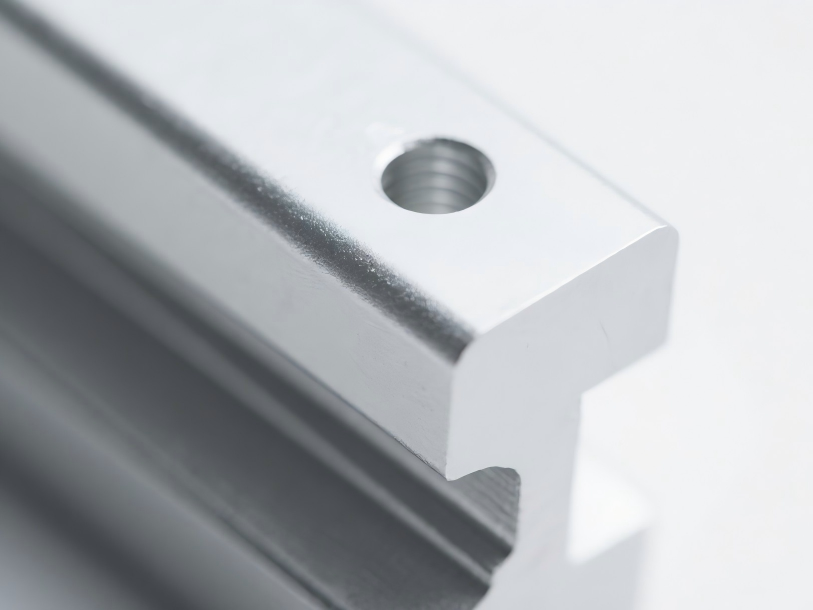

Direct Machined Surface (Ra 2.5μm / Ra 98μin)

Clear, Light Gold, Gray, Black

High Gloss (25-35 GU)

Clear treatment: Average thickness 1.8-2.5μm, minimum local thickness 1μm; Colored treatment: Average thickness 2.5-3.5μm, minimum local thickness 1.5μm

Retains original machining marks, transparent oxide layer reveals base material

Fine Bead Blasting

Clear, Light Gold, Gray, Black

Matte (8-15 GU)

Same as above

Uniform fine sand-blasted effect, eliminates machining marks

Enhanced Bead Blasting

Clear, Light Gold, Gray, Black

Deep Matte (<5 GU)

Same as above

Surface with pronounced granular feel, strong tactile texture

Mechanical Brushing (Ra 0.8μm / Ra 31μin)

Clear, Light Gold, Gray, Black

High Gloss (30-40 GU)

Same as above

Surface displays uniform unidirectional brushed pattern, distinct directional luster

Core advantages of Chromic Acid Anodizing (Type I):

Optimal fatigue performance Minimal dimensional change

Effective penetration capability Excellent salt spray environment corrosion resistance

Superior secondary processing compatibility Temperature stability

20+ Years of Precision Expertise: More than 20 years of custom machining excellence.

Global Quality Standards: International quality protocols meet the exacting requirements of European, American, and Asian markets.

Complete Manufacturing Solution: Full industrial chain across automotive, marine, medical, and semiconductor, etc.

Machined Surface

(Ra 3.2μm)

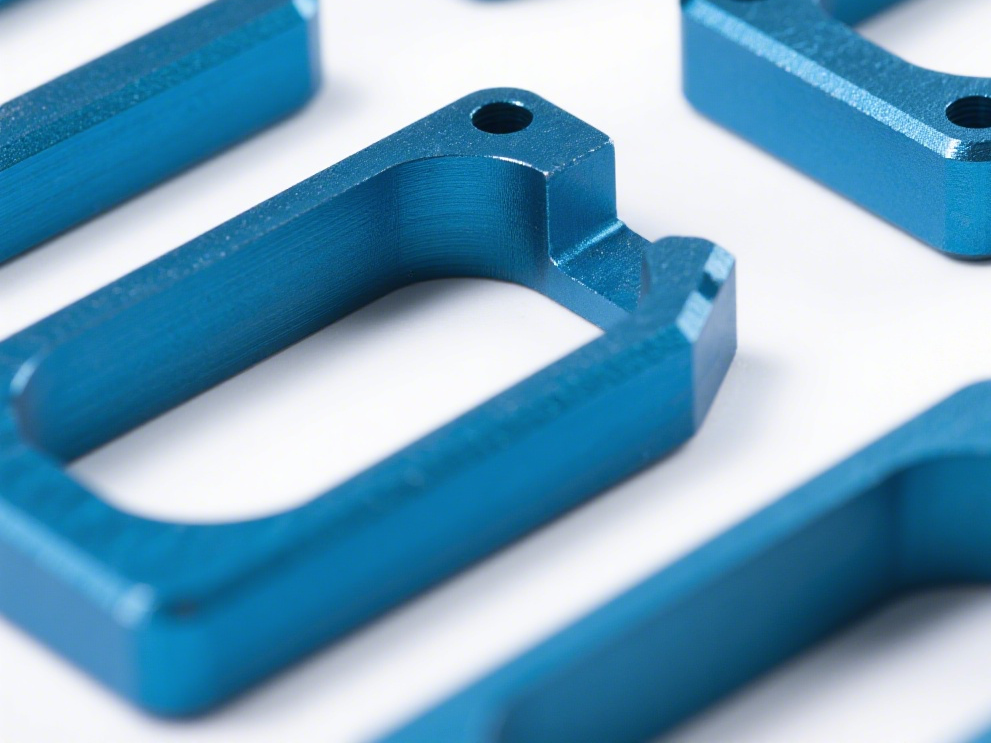

Clear, Black, Red, Blue, Gold, Orange

High Gloss

(>20 GU)

Clear: avg 10μm (min 8μm)

Colored: avg 15μm (min 12μm)

Original machining marks remain visible

Machined Surface

(Ra 3.2μm)

Clear, Black, Red, Blue, Gold, Orange

High Gloss

(>20 GU)

Clear: avg 10μm (min 8μm)

Colored: avg 15μm (min 12μm)

Original machining marks remain visible

Matte Bead Blasting

Clear, Black, Red, Blue, Gold, Orange

Matte finish

(<10 GU)

Same as above

Uniform grainy texture with matte appearance

Glossy Bead Blasting

Clear, Black, Red, Blue, Gold, Orange

Maintains gloss

(>20 GU)

Same as above

Textured surface with maintained glossiness

Brushed Finish

(Ra 1.2μm)

Clear, Black, Red, Blue, Gold, Orange

Directional gloss

(>20 GU)

Same as above

Distinct directional brushing patterns visible

Important Notes:

1. Actual color results may vary slightly due to alloy composition, surface treatment methods, and batch variations

2. All colors can be combined with different surface treatment processes to customize your ideal visual and tactile effect

3. Sample service available to ensure your color selection perfectly matches project requirements

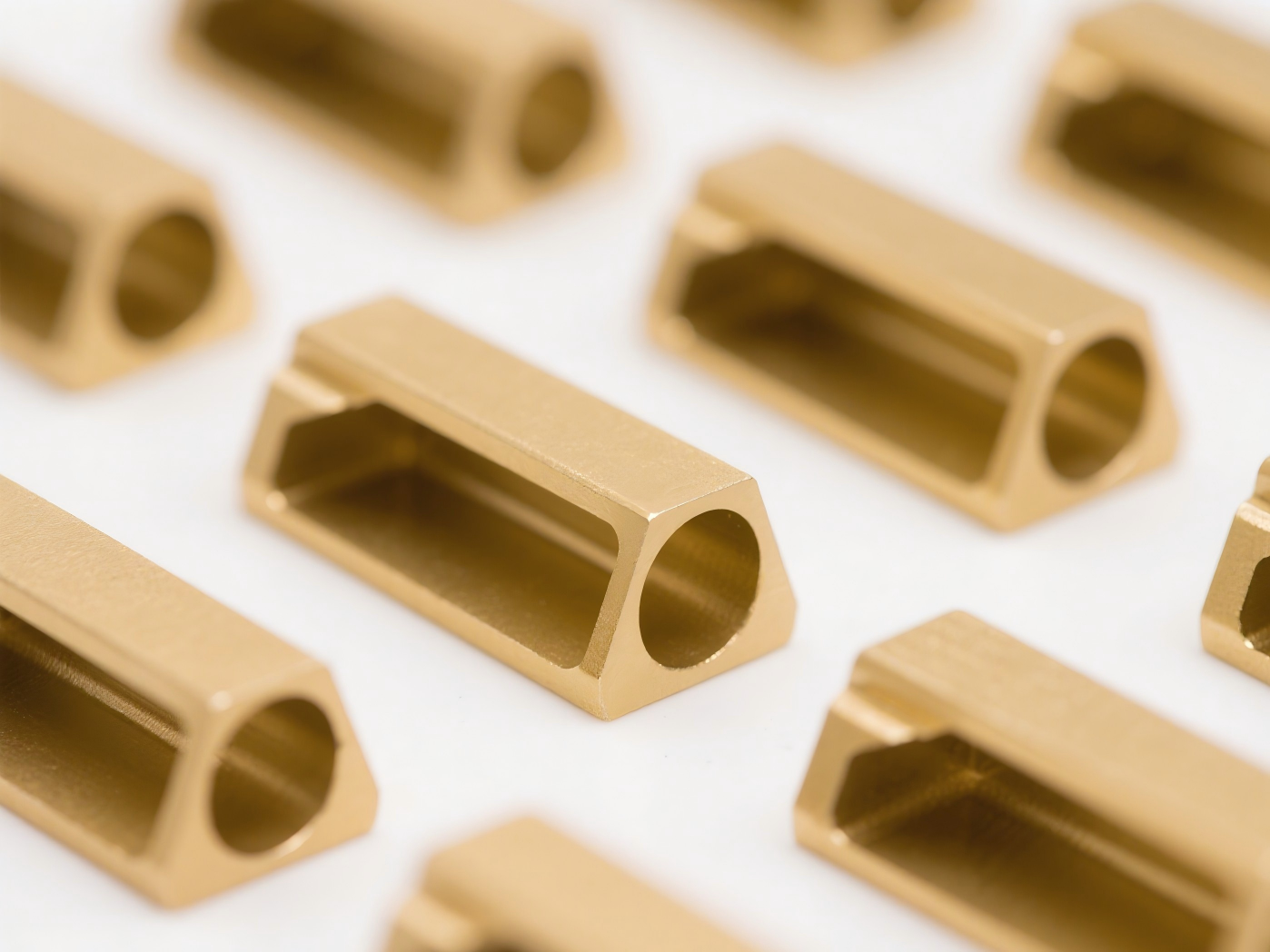

Bring ideal aesthetics and protection to your aluminum components with our six carefully selected standard color options, meeting diverse design and functional requirements.

Perfect match for: Aerospace components, medical devices, optical instrument frames

Perfect match for: Precision instruments, photography equipment, high-end consumer electronics

Perfect match for: Safety equipment, sporting goods, design-forward industrial components

Perfect match for: Precision medical equipment, scientific instruments, hydraulic system components

Perfect match for: Warning function parts, outdoor equipment, specialized industrial applications

Perfect match for: High-end consumer goods, decorative industrial components, trophies and awards

Unlock rapid turnaround times for your CNC prototypes and parts. Enjoy our standard 7-day lead times. Simply upload your design to verify eligibility.

Machined Surface

(Ra 3.2μm / Ra 126μin)

Black, Natural

(thicker layers will appear darker)

Not for cosmetic use

35 to 50μm

(0.0013″ to 0.0019″)

Parts are anodized directly after machining. Machining marks will be visible.

Bead Blasted

(Glass beads #120)

Black, Natural

(thicker layers will appear darker)

Cosmetic on request

35 to 50μm

(0.0013″ to 0.0019″)

Can be slightly visible if parts are “Not Cosmetic”

Completely removed if parts are “Cosmetic”

Compatible Alloys:

Optimal fatigue performance Minimal dimensional change

Effective penetration capability Excellent salt spray environment corrosion resistance

Superior secondary processing compatibility Temperature stability

Share your project requirements with us and let our expert team provide high-precision solutions for your challenges. 20 years of exceptional craftsmanship, dedicated to your next successful project. Contact us today to start our partnership journey.

© 2025 ROOPI. All rights reserved

20 Years of Expert Manufacturing | Complete Type II & Type III Anodizing Services | Six Standard Colors & Custom Options | Strict Compliance with International Quality Standards

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215312, Jiangsu, P.R. China

Email: sales92@partstailor.com

Phone: +86-18551199566

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215312, Jiangsu, P.R. China

Email: sales92@partstailor.com

Phone: +86-18551199566

Subscribe to receive our latest news and innovations directly in your inbox.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.