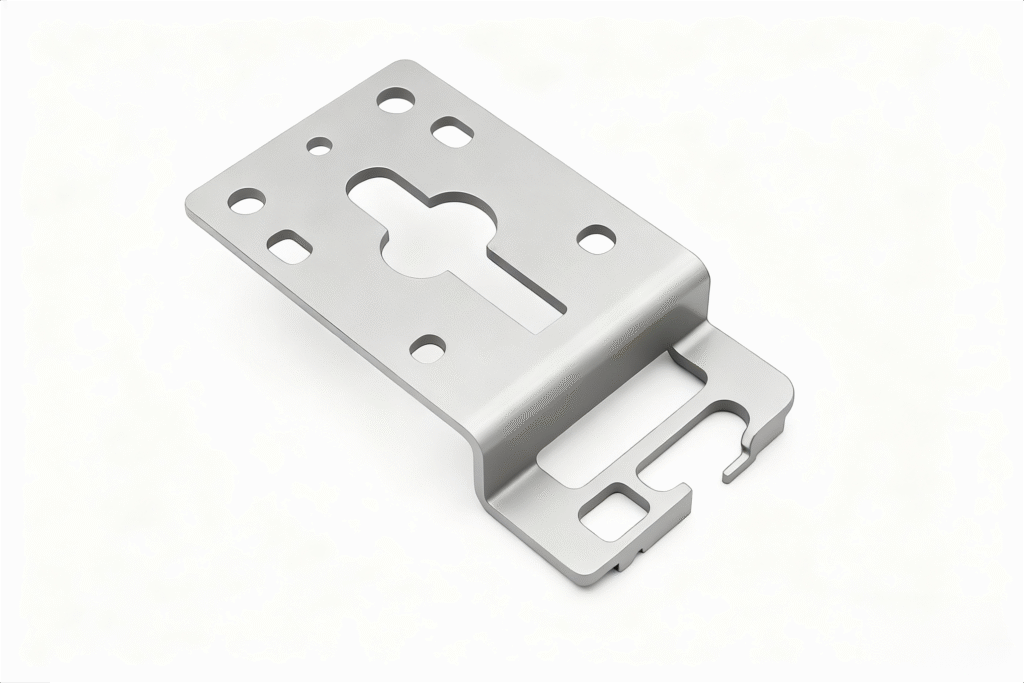

Whether you need a single prototype or a full-scale production run, our advanced CNC equipment and skilled technicians ensure your components are manufactured to exact specifications every time.

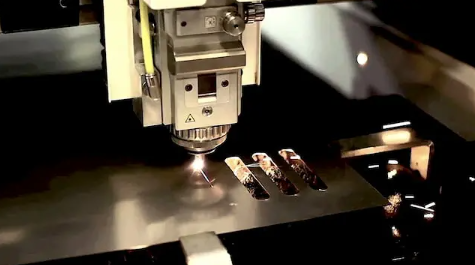

Laser cutting uses precision laser beams to cut, etch, or engrave sheet metal with exceptional accuracy. Our advanced CNC laser cutters achieve clean edges and complex patterns according to your specifications, handling materials up to 20mm thick with tolerances of ±0.1mm.

Bending applies force to sheet metal to shape it into various geometries, such as U-shapes, V-shapes, or channel forms. Our precision CNC press brakes ensure accurate angles and clean bends across different material thicknesses, delivering complex formed components that meet exact design specifications.

Welding joins metal pieces using heat, pressure, or both to form strong bonds. Our expert team with 30+ years of experience provides MIG, TIG, and spot welding for various metals, including aluminum, steel, and stainless steel, delivering durable joints with minimal distortion.

Punching creates holes or shapes by forcing a tool through metal sheets. Our CNC punching machines deliver clean cuts with precise dimensions and minimal material deformation, ideal for high-volume production requiring consistent quality across thousands of identical parts.

Riveting is a semi-permanent joining method using mechanical fasteners to connect sheet metal parts. It’s faster and more cost-effective than welding for many applications, providing reliable connections where disassembly might be needed later or where different materials require secure fastening.

Stamping uses dies and presses to shape flat metal sheets into different forms. Our precision equipment creates complex, three-dimensional designs through cold-forming techniques, ensuring dimensional accuracy and consistency for production across automotive, electronics, and industrial applications.

Unlock rapid turnaround times for your sheet metal fabrication prototypes and parts. Enjoy our standard 7-day lead times. Simply upload your design to verify eligibility.

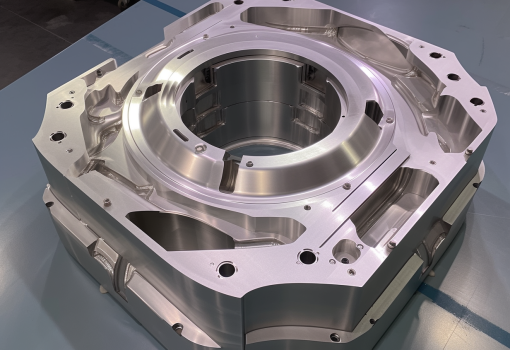

We’re not just a provider; we’re your partner in delivering precise CNC machining solutions that meet the rigorous demands of your projects. We specialize in custom CNC machined parts for industries including, but not limited to, the following:

In vacuum technology, sheet metal fabrication is essential for creating high-precision chambers and components that maintain stringent vacuum integrity. We produce vacuum chambers with precise welding techniques and surface finishing that ensure leak-free operation for semiconductor processing equipment, research facilities, and industrial vacuum systems. Our expertise includes fabricating complex geometries with critical tolerances required for PVD and PECVD systems.

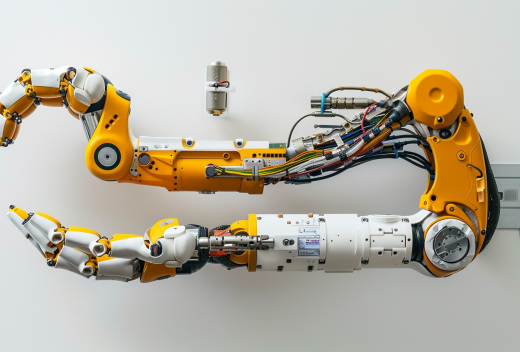

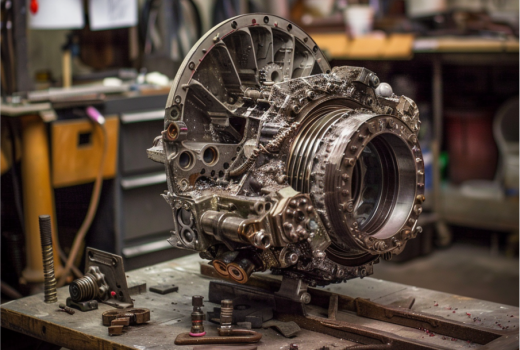

We specialize in creating custom, high-precision components for a broad range of industrial machinery, from automated assembly lines , electronic devices enclosures, and robotics to heavy-duty manufacturing equipment and engine parts.

For maritime applications, we fabricate corrosion-resistant sheet metal components that withstand harsh marine environments. Our services include custom navigation equipment housings, helm control panels, yacht hardware, and specialized sailing components. Using marine-grade stainless steel and aluminum alloys, we produce durable, lightweight parts that combine aesthetic appeal with functional integrity for both recreational vessels and commercial ships.

The medical sector demands exceptional precision and cleanliness in sheet metal components. We fabricate sterile equipment enclosures, surgical tool trays, imaging system frames, and diagnostic device housings that comply with strict regulatory requirements. Our ISO 13485 certification ensures that all medical components meet industry standards for safety, cleanliness, and precision, supporting critical healthcare applications worldwide.

Aerospace sheet metal fabrication requires extraordinary precision and material integrity. We produce lightweight yet robust components for aircraft interiors, control system housings, equipment racks, and satellite structures. Using specialized aerospace alloys and advanced forming techniques, our components meet rigorous aviation standards for weight optimization, stress resistance, and reliability in extreme conditions.

In automotive manufacturing, our sheet metal expertise delivers precision components for both production vehicles and specialized prototypes. We fabricate complex brackets, structural reinforcements, heat shields, and custom body panels that meet exacting OEM specifications. Our IATF 16949:2016 certification ensures consistent quality for automotive supply chains, with capabilities spanning from prototype development to high-volume production runs.

Embracing a culture of quality excellence, our company is certified to ISO 9001:2015, demonstrating our commitment to customer satisfaction and our capability to consistently deliver high-quality products and services. To ensure precise validation of part conformity, we adhere strictly to drawing specifications and employ a comprehensive suite of precision metrology equipment, including Coordinate Measuring Machines (CMMs), for full-dimensional inspection. Detailed inspection reports are provided, guaranteeing that every delivery meets our clients’ stringent requirements.

Whatever metals or plastics , at Baichuan, you can select freely for your unique demand

| Aluminum 1050A | Al | Aluminum 2011 | Al-Cu-Pb-Bi | Aluminum 3003 | Al-Mn | Aluminum 4032 | Al-Si-Mg-Cu-Ni | Aluminum 5005 | Al-Mg | Aluminum 6005A | Al-Mg-Si | Aluminum 7005 | Al-Zn-Mg-Mn-Cu-Cr |

| Aluminum 1060 | Al | Aluminum 2014 | Al-Cu-Si-Mn-Mg | Aluminum 3004 | Al-Mn-Mg | Aluminum 5052 | Al-Mg-Cr | Aluminum 6061 | Al-Mg-Si-Cu | Aluminum 7050 | Al-Zn-Mg-Cu-Zr | |

| Aluminum 1100 | Al-Cu | Aluminum 2017A | Al-Cu-Mg-Si-Mn | Aluminum 5083 | Al-Mg-Mn-Cr | Aluminum 6063 | Al-Mg-Si | Aluminum 7075 | Al-Zn-Mg-Cu-Cr | ||

| Aluminum 2024 | Al-Cu-Mg-Mn | Aluminum 5086 | Al-Mg-Mn-Cr | Aluminum 6082 | Al-Mg-Si-Mn |

| Stainless steel 304| UNS S30400 | Stainless steel 201| UNS S20100 | Stainless steel 430| UNS S43000 | Stainless steel 17-4PH| UNS S17400 |

| Stainless steel 304L| UNS S30403 | Stainless steel 409| UNS S40900 | ||

| Stainless steel 316| UNS S31600 | Stainless steel 410| UNS S41000 | ||

| Stainless steel 316L| UNS S31603 | Stainless steel 420| UNS S42000 | ||

| Stainless steel 321| UNS S32100 |

| ASTM A36 |

| SAE 1018 |

| SAE 1020 |

| EN 10025 S235JR |

| GB/T 700 Q235B |

| A366 |

| ASTM A572 | UNS G41300 | UNS G43400 | High-Speed Steel, HSS | UNS H61500 |

| ASTM A656 | UNS G41400 | Cold Work Tool Steel | UNS H92600 | |

| EN 10025 S355 | Hot Work Tool Steel |

| Alloy steel 4140 |

| Alloy steel 4340 |

| Alloy steel 1215 |

| Tool steel D2 | 1.2379 |

| Tool steel A2 | 1.2363 |

| Tool steel O1 |

| Tool steel A3 |

| Tool steel S7 |

| Tool steel H13 | 1.2344 |

| Titanium Grade 2 |

| Titanium Grade 1 |

| Titanium Grade 5 | 3.7164 | Ti6Al4V |

| Brass H62 | Brass C26000 |

| Brass H65 | Brass C28000 |

| Brass H68 | Brass C36000 |

| Brass H70 |

| Copper T1 | Copper TU1 | Copper TP1 | Copper C14500 |

| Copper T2 | Copper TU2 | Copper TP2 | Copper C17200 |

| Copper C17300 |

| Inconel 718 |

| Inconel 600 |

| Inconel 625 |

| Inconel X-750 |

Invar

| C51000 | C95400 | C86300 | C65500 |

| C90700 | C95800 |

| C22000 | C33000 | C44300 | C67500 |

| C23000 | C36000 | C46400 | |

| C26000 | C37700 | ||

| C26800 | C38500 | ||

| C27000 | |||

| C28000 |

Even any material beyond our table is achievable.

| Delrin (POM-H) |

| Acetal (POM-C) |

| Nylon 6 |

| PA 6 GF30 |

ABS

PEEK

Teflon

| HDPE |

| UHMWPE |

PVC

PMMA (Acrylic)

PET

| PP |

| PP+GF(30%) |

Garolite G-10

FR4

Even any material beyond our table is achievable.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.