We offer processing services including plastic, wood, and metal. The following materials are just some of the ones we commonly use. If you need special materials that we don’t have in stock locally, we welcome you to provide your own to keep your project running smoothly. Check this article to know more about material selection.

ABS material boasts outstanding durability, superior impact resistance, and smooth machinability, making it ideal for creating sturdy and reliable machined components.

POM material delivers exceptional stiffness, remarkable dimensional accuracy, and minimal friction, positioning it as the prime choice for fabricating precision-engineered mechanical parts.

Nylon material provides robust strength, outstanding wear resistance, and superior elasticity, making it perfectly suited for manufacturing parts designed to endure high mechanical stress.

Teflon material is celebrated for its unparalleled chemical resistance, minimal friction, and ability to withstand high temperatures, making it the go-to choice for applications in aggressive chemical conditions.

Teflon material is celebrated for its unparalleled chemical resistance, minimal friction, and ability to withstand high temperatures, making it the go-to choice for applications in aggressive chemical conditions.

PMMA material shines with superior light transmission, robust strength, and smooth machinability, making it an outstanding option for both optical enhancements and visually appealing applications.

PEEK material stands out with its exceptional strength, resistance to high temperatures, and favorable machinability, setting it apart as the premium choice for demanding high-performance environments.

PC material is renowned for its superior impact resistance, outstanding dimensional stability, and clear visibility, making it the ideal candidate for crafting precise and durable machined components.

Whatever metals or plastics , at Baichuan, you can select freely for your unique demand

| Aluminum 1050A | Al | Aluminum 2011 | Al-Cu-Pb-Bi | Aluminum 3003 | Al-Mn | Aluminum 4032 | Al-Si-Mg-Cu-Ni | Aluminum 5005 | Al-Mg | Aluminum 6005A | Al-Mg-Si | Aluminum 7005 | Al-Zn-Mg-Mn-Cu-Cr |

| Aluminum 1060 | Al | Aluminum 2014 | Al-Cu-Si-Mn-Mg | Aluminum 3004 | Al-Mn-Mg | Aluminum 5052 | Al-Mg-Cr | Aluminum 6061 | Al-Mg-Si-Cu | Aluminum 7050 | Al-Zn-Mg-Cu-Zr | |

| Aluminum 1100 | Al-Cu | Aluminum 2017A | Al-Cu-Mg-Si-Mn | Aluminum 5083 | Al-Mg-Mn-Cr | Aluminum 6063 | Al-Mg-Si | Aluminum 7075 | Al-Zn-Mg-Cu-Cr | ||

| Aluminum 2024 | Al-Cu-Mg-Mn | Aluminum 5086 | Al-Mg-Mn-Cr | Aluminum 6082 | Al-Mg-Si-Mn |

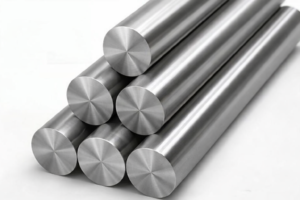

| Stainless steel 304| UNS S30400 | Stainless steel 201| UNS S20100 | Stainless steel 430| UNS S43000 | Stainless steel 17-4PH| UNS S17400 |

| Stainless steel 304L| UNS S30403 | Stainless steel 409| UNS S40900 | ||

| Stainless steel 316| UNS S31600 | Stainless steel 410| UNS S41000 | ||

| Stainless steel 316L| UNS S31603 | Stainless steel 420| UNS S42000 | ||

| Stainless steel 321| UNS S32100 |

| ASTM A36 |

| SAE 1018 |

| SAE 1020 |

| EN 10025 S235JR |

| GB/T 700 Q235B |

| A366 |

| ASTM A572 | UNS G41300 | UNS G43400 | High-Speed Steel, HSS | UNS H61500 |

| ASTM A656 | UNS G41400 | Cold Work Tool Steel | UNS H92600 | |

| EN 10025 S355 | Hot Work Tool Steel |

| Alloy steel 4140 |

| Alloy steel 4340 |

| Alloy steel 1215 |

| Tool steel D2 | 1.2379 |

| Tool steel A2 | 1.2363 |

| Tool steel O1 |

| Tool steel A3 |

| Tool steel S7 |

| Tool steel H13 | 1.2344 |

| Titanium Grade 2 |

| Titanium Grade 1 |

| Titanium Grade 5 | 3.7164 | Ti6Al4V |

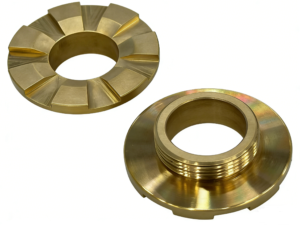

| Brass H62 | Brass C26000 |

| Brass H65 | Brass C28000 |

| Brass H68 | Brass C36000 |

| Brass H70 |

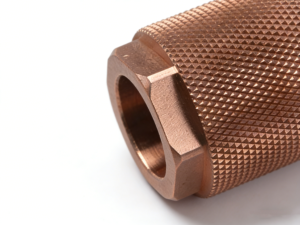

| Copper T1 | Copper TU1 | Copper TP1 | Copper C14500 |

| Copper T2 | Copper TU2 | Copper TP2 | Copper C17200 |

| Copper C17300 |

| Inconel 718 |

| Inconel 600 |

| Inconel 625 |

| Inconel X-750 |

Invar

| C51000 | C95400 | C86300 | C65500 |

| C90700 | C95800 |

| C22000 | C33000 | C44300 | C67500 |

| C23000 | C36000 | C46400 | |

| C26000 | C37700 | ||

| C26800 | C38500 | ||

| C27000 | |||

| C28000 |

Even any material beyond our table is achievable.

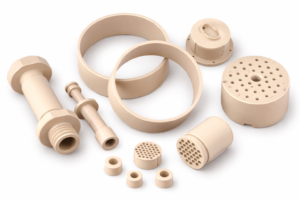

| Delrin (POM-H) |

| Acetal (POM-C) |

| Nylon 6 |

| PA 6 GF30 |

ABS

PEEK

Teflon

| HDPE |

| UHMWPE |

PVC

PMMA (Acrylic)

PET

| PP |

| PP+GF(30%) |

Garolite G-10

FR4

Even any material beyond our table is achievable.

We offer processing services including plastic, wood, and metal. The following materials are just some of the ones we commonly use. If you need special materials that we don’t have in stock locally, we welcome you to provide your own to keep your project running smoothly. Check this article to know more about material selection.

ABS material boasts outstanding durability, superior impact resistance, and smooth machinability, making it ideal for creating sturdy and reliable machined components.

POM material delivers exceptional stiffness, remarkable dimensional accuracy, and minimal friction, positioning it as the prime choice for fabricating precision-engineered mechanical parts.

Nylon material provides robust strength, outstanding wear resistance, and superior elasticity, making it perfectly suited for manufacturing parts designed to endure high mechanical stress.

Teflon material is celebrated for its unparalleled chemical resistance, minimal friction, and ability to withstand high temperatures, making it the go-to choice for applications in aggressive chemical conditions.

PMMA material shines with superior light transmission, robust strength, and smooth machinability, making it an outstanding option for both optical enhancements and visually appealing applications.

PEEK material stands out with its exceptional strength, resistance to high temperatures, and favorable machinability, setting it apart as the premium choice for demanding high-performance environments.

PC material is renowned for its superior impact resistance, outstanding dimensional stability, and clear visibility, making it the ideal candidate for crafting precise and durable machined components.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.