We provide mission-critical components to global innovators in a variety of industries, including aerospace and the semiconductor industry.

Our 24/7 engineering team ensures that you’re on track from prototype to production – that’s why 100 + companies rely on our responsive manufacturing ecosystem.

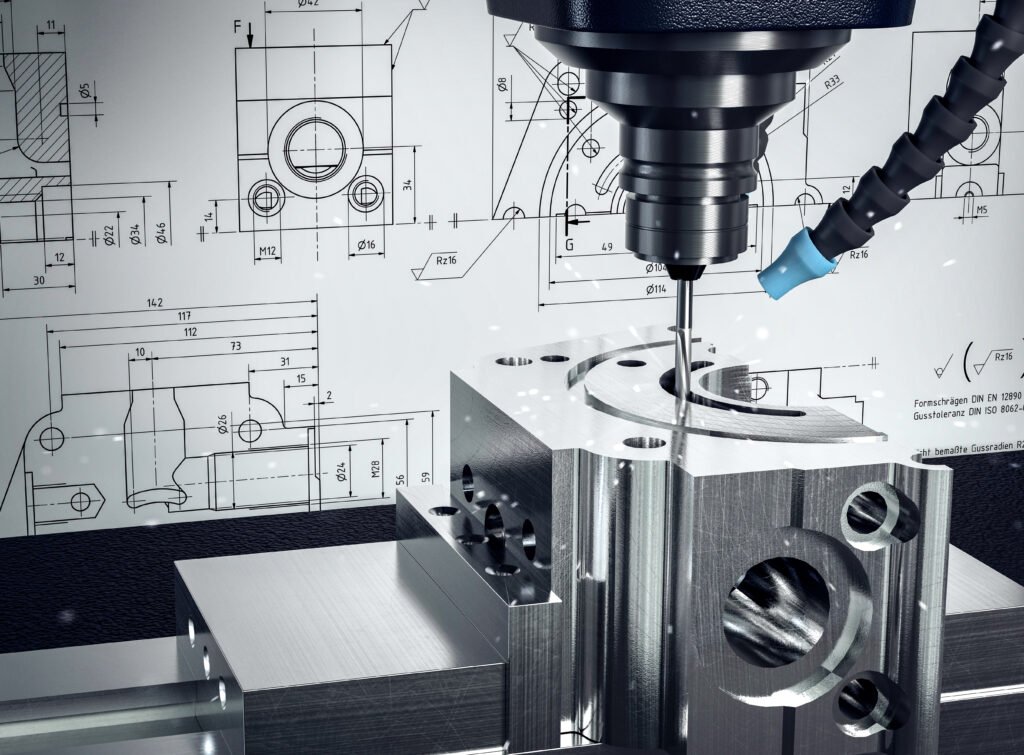

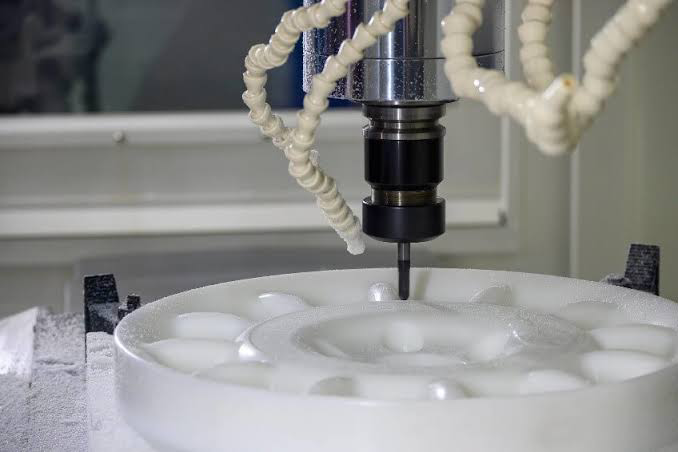

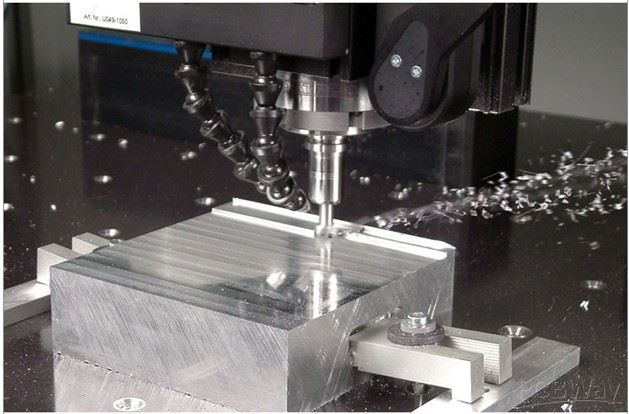

Our CNC milling capability elevates precision engineering to an industrial scale. From rapid prototyping to high-volume production, our advanced multi-axis machining centers deliver exceptional accuracy across diverse industries. With over 40 state-of-the-art CNC machines, BaiChuan Precision expertly transforms complex designs into reality, processing both metal and plastic materials to exacting specifications. We combine technical excellence with cost-efficiency and rapid turnaround, including complimentary proofing to guarantee your complete satisfaction.

Embracing a culture of quality excellence, our company is certified to ISO 9001:2015, demonstrating our commitment to customer satisfaction and our capability to consistently deliver high-quality products and services. To ensure precise validation of part conformity, we adhere strictly to drawing specifications and employ a comprehensive suite of precision metrology equipment, including Coordinate Measuring Machines (CMMs), for full-dimensional inspection. Detailed inspection reports are provided, guaranteeing that every delivery meets our clients’ stringent requirements.

We offer a vast range of materials to bring your designs to life. Our expertise encompasses both metals and plastics, ensuring we can meet the diverse needs of our global clientele with precision and efficiency.

Metals, known for their durability and strength, are extensively utilized in CNC milling to achieve parts that withstand demanding applications. BaiChuan Precision specializes in milling a comprehensive selection of metals such as aluminum, stainless steel, brass, copper, bronze, magnesium, titanium, zinc, and more, offering you parts that not only meet but exceed industry standards.

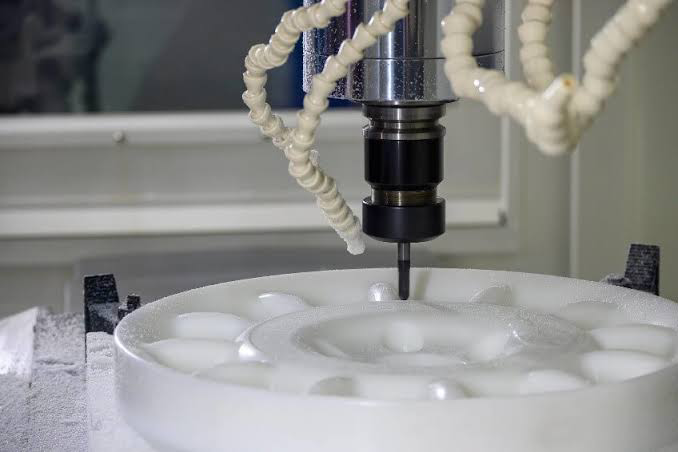

Plastics are a popular choice in CNC milling for their versatility and the broad spectrum of properties they offer, catering to various applications. At BaiChuan, we work with a wide array of plastics including ABS, acrylic, PC, PVC, Nylon, POM, PE, Teflon, and more, ensuring your parts meet the exact specifications and performance requirements.

Expanding our material portfolio, BaiChuan Precision also offers CNC milling services for wood. Wood machining requires distinct precision and care to highlight its natural beauty while achieving the desired functionality. Whether it’s for custom furniture components, intricate architectural models, or any other application where the warmth and organic feel of wood are preferred, we have the technology and expertise to deliver with the highest standards.

Prototyping

Can be selected

Max work range

Final Passed Yield

At BaiChuan Precision, we understand that the cornerstone of exceptional CNC machining lies in stringent adherence to tolerances and superior surface finishes. Our dedication to these principles is unwavering, as they are critical in preventing costly errors and ensuring that each product not only meets but exceeds our clients’ expectations.

Machining Tolerances Unveiled: In the realm of CNC machining, the term “tolerance” refers to the permissible limit of variation in a physical dimension. It’s a vital consideration in the customization of parts, ensuring that every piece meets its intended specifications with precision.

We are proud to adhere to the renowned ISO 2768 standards for both metal and plastic machined parts. This commitment guarantees that our offerings align with the pinnacle of industry quality. Our typical CNC machining tolerances range from ±0.005″ (±0.125mm) to an even more precise ±0.002″ (±0.05mm), with the capability to achieve the exceptionally tight tolerance of ±0.01mm when required.

Surface Finish Standards – A Reflection of Quality: The surface finish of a part is more than just its texture or appearance; it plays a significant role in the part’s functionality and overall aesthetics. It’s an element that can significantly influence the performance and longevity of the component.

Our offerings include a variety of surface finish standards to cater to diverse needs and applications. From the typically machined surface roughness of Ra 3.2-1.6 μm, to the smoother finishes of Ra 1.6-0.8 μm, and extending to our super-finished surfaces with roughness levels of Ra 0.8-0.2 μm, BaiChuan Precision ensures that your parts are not just made, but crafted to perfection.

You will get quotation in 1 hour after providing us 2D drawings(DWG/DXF) or 3D drawings(STEP, IGES or X_T) with information of quantities and surface treament. All drawings are scure and strictly confidential.

After receving advance payment, the production department will confirm all technical details and start to process. Delivery time is 1-3 dyas for prototyping and 7-30 days for production.

The QC department will check each dimension with CMM and show the report and pictures of each angle for your confirmation.

Varity shipping method to choose including: express, air, sea, train. Common choices: FedEx, UPS, and DHL.

BaiChuan Precision is your ultimate destination for CNC milling solutions, catering to every need from single custom parts to large-scale production batches.

Material Mastery: Our capabilities extend across the spectrum of engineering plastics and metals, enabling the creation of custom milled parts tailored to your specific needs.

Precision Perfected: BaiChuan Precision’s parts stand out for their dimensional stability, exceptional repeatability, and unmatched precision machining, not to mention their superior electrical conductivity.

Efficient Engineering: Our state-of-the-art 5-axis CNC milling machines streamline the production process, allowing for the machining of multiple surfaces in a single setup. This not only enhances efficiency but also ensures the high adaptability and flexibility of parts machining.

Complexity Conquered: BaiChuan Precision specializes in machining parts with complex geometries or stringent tolerance requirements, from intricate mold parts to sophisticated housing components.

Automation and Efficiency: Leveraging a high degree of automation, our CNC milling services boast unparalleled production efficiency, with the capability to operate continuously 24/7, facilitating seamless production management.

BaiChuan Precision’s CNC milling expertise is a critical component in the innovation and maintenance of various sectors

√ Electronics – We produce electronics hardware, housings, and other intricate parts that are the backbone of the electronics industry.

√ Automotive – BaiChuan Precision plays a pivotal role in the automotive industry, providing custom parts like gearboxes and turbochargers that drive innovation.

√ Semiconductor Industry: In the semiconductor realm, CNC milling plays a critical role in fabricating intricate parts for semiconductor manufacturing equipment, ensuring high precision and adaptability in the fast-evolving tech landscape.

√ Aerospace – We are at the forefront of aerospace engineering, creating essential components for engines, transmissions, and more, embodying precision and durability.

√ Sailboat – Our expertise spans the crafting of durable and corrosion-resistant parts for sailboats such as rudder stocks, and mast fittings, alongside precision-engineered deck hardware and custom cockpit components.

√ Medical – Our precision milling crafts orthopedic implants, surgical instruments, and other vital medical devices.

While both CNC milling and CNC turning are efficient and precise subtractive manufacturing processes controlled by CNC technology, they differ mainly in how the material is removed and the types of parts they are best suited for.

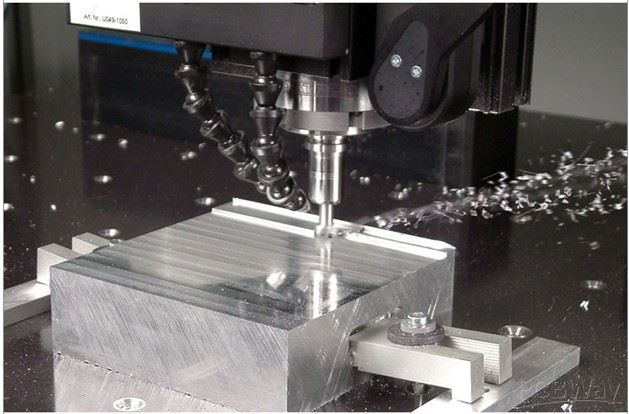

CNC Milling: In milling, the workpiece is stationary, and the cutting tools rotate at high speeds to remove material in various directions. Milling is incredibly versatile, capable of producing complex shapes and features such as slots, holes, and contours. It’s ideal for parts with intricate designs and for machining parts on multiple sides.

CNC Turning: Turning involves securing the material in a chuck and rotating it while a stationary cutting tool is applied to create cylindrical shapes. This process is best suited for round or tubular shapes where the primary operation is to reduce the diameter of the material. CNC turning is highly efficient for producing parts like shafts, knobs, and bushings.

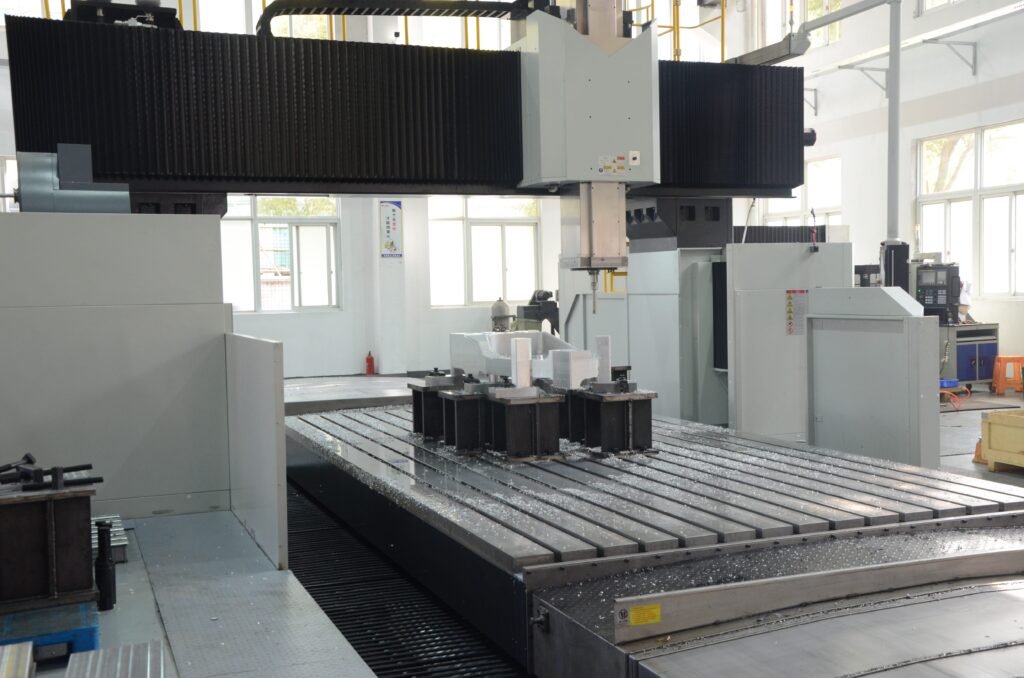

Have you received a rejection letter from a manufacturer saying that their conventional methods can’t be used for advanced fabrication of too large or heavy parts? That would never happen to you with BaiChuan Precision. Our large CNC machining services are great for fabricating unusually sized parts and creating bizarre-looking prototypes and models. That’s how we serve any business and industry, including:

BaiChuan Precision has been doing it for large and small pieces for 25 years. We never keep you flummoxed with rejection letters and are always committed to providing top-quality large parts in a fraction of the time.

We can machine large parts efficiently, reducing the cost and time you would be told to invest with other manufacturers. Our large-part machine shop is equipped with configurable machinery and tooling so that we can tune our CNC machines to the desired dimensions. You can be confident that your machined parts will match your exact requirements, no matter how intricate the specifications are.

With the BaiChuan Precision large-part CNC machining shop, you can get:

We abide by strict QC measures throughout the process to ensure your large pieces are of the highest quality. Each step is scrutinized for accuracy – from initial design, material selection, and machining to final assembly.

Our CNC milling equipment is as configurable for large items as for tiny parts. It delivers exceptional accuracy for unusual shapes and designs and can be set up for various materials, including metal, metal alloys, plastics, and custom non-metal materials. With our large CNC milling machines, you can benefit from increased speed, repeatability, and productivity to create complex parts.

You can also take advantage of BaiChuan Precision finishing services, such as sanding, polishing, coating, etc. This will ensure your parts are ready for use as soon as they come out of the machine.

We have proficiency in handling large projects. Let’s get started on yours!

Yes , we can sign the NDA before you send the drawing.

In General , For sample , it is take about 5-7 days , and for mass production, it Is take 14-20 days.

We don’t have MOQ and accept orders of any quantity.

We’d love to hear from you! Send us a message using the form opposite, or email us.

Oversized parts call for the workspace considerations you never have to worry about when fabricating standard pieces. They involve setting up CNC machines for vertical or horizontal accessibility, ensuring advanced heat protection for tooling and engineers, and adopting additional production techniques to avoid workpiece distortion.

The good news? BaiChuan Precision knows its way around unconventional pieces and workspace preparation. We share your vision for sophisticated custom items that push the boundaries of design and redefine what’s possible with large part machining. We utilize high-performance loaders and precision linear guides in temperature-controlled environments to ensure your components can be big and flawless.

Whatever oversized pieces you want us to produce, we think through all considerations so you don’t have to. Our processes are proven to fabricate large and extra-large parts for:

These are just some industrial components we can help you with. When projecting an imposing piece of machinery or structure, contact BaiChuan Precision, one of the largest CNC machine manufacturers globally.

3-&5-Axis milling service.

Machined Prototypes in as fast as 3 day.

Certificated

Prototyping

Can be selected

Final Passed Yield

CNC milling is a subtractive manufacturing process that utilizes computer numerical control (CNC) systems to automate the precise removal of material from a solid workpiece. It starts with a detailed CAD design, which is then converted into a CNC program. This program dictates the movements of the milling machine’s tools, enabling them to cut along multiple axes and create complex shapes and dimensions with high precision. The process strategically removes material to shape the final product according to the predefined specifications.

With a fleet of over 30 advanced CNC machines, BaiChuan Precision offers unmatched custom CNC milling services for both metal and plastic components. Our capabilities range from producing the simplest of parts to the most intricate designs demanded by our global clientele. Our commitment to excellence is reflected not just in the parts we produce but in our ability to deliver them with exceptional cost-efficiency and speed, including complimentary proofing to ensure your utmost satisfaction.

BaiChuan Precision stands at the forefront of CNC milling technology with our 3-axis, 4-axis, and 5-axis capabilities. Our 3-axis and 4-axis machines excel in crafting parts with straightforward geometries, serving as the backbone of our manufacturing processes.

Elevating our services to the pinnacle of precision, our 5-axis CNC milling introduces unparalleled efficiency and geometric complexity. This advanced capability allows us to execute your most ambitious projects with a single setup, ensuring accuracy that sets new industry standards. BaiChuan Precision is your partner in turning intricate designs into reality, leveraging decades of expertise and a state-of-the-art fleet to bring your vision to life.

We offer a vast range of materials to bring your designs to life. Our expertise encompasses both metals and plastics, ensuring we can meet the diverse needs of our global clientele with precision and efficiency.

Metals, known for their durability and strength, are extensively utilized in CNC milling to achieve parts that withstand demanding applications. BaiChuan Precision specializes in milling a comprehensive selection of metals such as aluminum, stainless steel, brass, copper, bronze, magnesium, titanium, zinc, and more, offering you parts that not only meet but exceed industry standards.

Plastics are a popular choice in CNC milling for their versatility and the broad spectrum of properties they offer, catering to various applications. At BaiChuan, we work with a wide array of plastics including ABS, acrylic, PC, PVC, Nylon, POM, PE, Teflon, and more, ensuring your parts meet the exact specifications and performance requirements.

Expanding our material portfolio, BaiChuan Precision also offers CNC milling services for wood. Wood machining requires distinct precision and care to highlight its natural beauty while achieving the desired functionality. Whether it’s for custom furniture components, intricate architectural models, or any other application where the warmth and organic feel of wood are preferred, we have the technology and expertise to deliver with the highest standards.

At BaiChuan Precision, we understand that the cornerstone of exceptional CNC machining lies in stringent adherence to tolerances and superior surface finishes. Our dedication to these principles is unwavering, as they are critical in preventing costly errors and ensuring that each product not only meets but exceeds our clients’ expectations.

Machining Tolerances Unveiled: In the realm of CNC machining, the term “tolerance” refers to the permissible limit of variation in a physical dimension. It’s a vital consideration in the customization of parts, ensuring that every piece meets its intended specifications with precision.

We are proud to adhere to the renowned ISO 2768 standards for both metal and plastic machined parts. This commitment guarantees that our offerings align with the pinnacle of industry quality. Our typical CNC machining tolerances range from ±0.005″ (±0.125mm) to an even more precise ±0.002″ (±0.05mm), with the capability to achieve the exceptionally tight tolerance of ±0.01mm when required.

Surface Finish Standards – A Reflection of Quality: The surface finish of a part is more than just its texture or appearance; it plays a significant role in the part’s functionality and overall aesthetics. It’s an element that can significantly influence the performance and longevity of the component.

Our offerings include a variety of surface finish standards to cater to diverse needs and applications. From the typically machined surface roughness of Ra 3.2-1.6 μm, to the smoother finishes of Ra 1.6-0.8 μm, and extending to our super-finished surfaces with roughness levels of Ra 0.8-0.2 μm, BaiChuan Precision ensures that your parts are not just made, but crafted to perfection.

You will get quotation in 1 hour after providing us 2D drawings(DWG/DXF) or 3D drawings(STEP, IGES or X_T) with information of quantities and surface treament. All drawings are scure and strictly confidential.

After receving advance payment, the production department will confirm all technical details and start to process. Delivery time is 1-3 dyas for prototyping and 7-30 days for production.

The QC department will check each dimension with CMM and show the report and pictures of each angle for your confirmation.

Varity shipping method to choose including: express, air, sea, train. Common choices: FedEx, UPS, and DHL.

BaiChuan Precision is your ultimate destination for CNC milling solutions, catering to every need from single custom parts to large-scale production batches.

Material Mastery: Our capabilities extend across the spectrum of engineering plastics and metals, enabling the creation of custom milled parts tailored to your specific needs.

Precision Perfected: BaiChuan Precision’s parts stand out for their dimensional stability, exceptional repeatability, and unmatched precision machining, not to mention their superior electrical conductivity.

Efficient Engineering: Our state-of-the-art 5-axis CNC milling machines streamline the production process, allowing for the machining of multiple surfaces in a single setup. This not only enhances efficiency but also ensures the high adaptability and flexibility of parts machining.

Complexity Conquered: BaiChuan Precision specializes in machining parts with complex geometries or stringent tolerance requirements, from intricate mold parts to sophisticated housing components.

Automation and Efficiency: Leveraging a high degree of automation, our CNC milling services boast unparalleled production efficiency, with the capability to operate continuously 24/7, facilitating seamless production management.

BaiChuan Precision’s CNC milling expertise is a critical component in the innovation and maintenance of various sectors

√ Electronics – We produce electronics hardware, housings, and other intricate parts that are the backbone of the electronics industry.

√ Automotive – BaiChuan Precision plays a pivotal role in the automotive industry, providing custom parts like gearboxes and turbochargers that drive innovation.

√ Semiconductor Industry: In the semiconductor realm, CNC milling plays a critical role in fabricating intricate parts for semiconductor manufacturing equipment, ensuring high precision and adaptability in the fast-evolving tech landscape.

√ Aerospace – We are at the forefront of aerospace engineering, creating essential components for engines, transmissions, and more, embodying precision and durability.

√ Sailboat – Our expertise spans the crafting of durable and corrosion-resistant parts for sailboats such as rudder stocks, and mast fittings, alongside precision-engineered deck hardware and custom cockpit components.

√ Medical – Our precision milling crafts orthopedic implants, surgical instruments, and other vital medical devices.

While both CNC milling and CNC turning are efficient and precise subtractive manufacturing processes controlled by CNC technology, they differ mainly in how the material is removed and the types of parts they are best suited for.

CNC Milling: In milling, the workpiece is stationary, and the cutting tools rotate at high speeds to remove material in various directions. Milling is incredibly versatile, capable of producing complex shapes and features such as slots, holes, and contours. It’s ideal for parts with intricate designs and for machining parts on multiple sides.

CNC Turning: Turning involves securing the material in a chuck and rotating it while a stationary cutting tool is applied to create cylindrical shapes. This process is best suited for round or tubular shapes where the primary operation is to reduce the diameter of the material. CNC turning is highly efficient for producing parts like shafts, knobs, and bushings.

Have you received a rejection letter from a manufacturer saying that their conventional methods can’t be used for advanced fabrication of too large or heavy parts? That would never happen to you with BaiChuan Precision. Our large CNC machining services are great for fabricating unusually sized parts and creating bizarre-looking prototypes and models. That’s how we serve any business and industry, including:

BaiChuan Precision has been doing it for large and small pieces for 25 years. We never keep you flummoxed with rejection letters and are always committed to providing top-quality large parts in a fraction of the time.

We can machine large parts efficiently, reducing the cost and time you would be told to invest with other manufacturers. Our large-part machine shop is equipped with configurable machinery and tooling so that we can tune our CNC machines to the desired dimensions. You can be confident that your machined parts will match your exact requirements, no matter how intricate the specifications are.

With the BaiChuan Precision large-part CNC machining shop, you can get:

We abide by strict QC measures throughout the process to ensure your large pieces are of the highest quality. Each step is scrutinized for accuracy – from initial design, material selection, and machining to final assembly.

Our CNC milling equipment is as configurable for large items as for tiny parts. It delivers exceptional accuracy for unusual shapes and designs and can be set up for various materials, including metal, metal alloys, plastics, and custom non-metal materials. With our large CNC milling machines, you can benefit from increased speed, repeatability, and productivity to create complex parts.

You can also take advantage of BaiChuan Precision finishing services, such as sanding, polishing, coating, etc. This will ensure your parts are ready for use as soon as they come out of the machine.

We have proficiency in handling large projects. Let’s get started on yours!

Oversized parts call for the workspace considerations you never have to worry about when fabricating standard pieces. They involve setting up CNC machines for vertical or horizontal accessibility, ensuring advanced heat protection for tooling and engineers, and adopting additional production techniques to avoid workpiece distortion.

The good news? BaiChuan Precision knows its way around unconventional pieces and workspace preparation. We share your vision for sophisticated custom items that push the boundaries of design and redefine what’s possible with large part machining. We utilize high-performance loaders and precision linear guides in temperature-controlled environments to ensure your components can be big and flawless.

Whatever oversized pieces you want us to produce, we think through all considerations so you don’t have to. Our processes are proven to fabricate large and extra-large parts for:

These are just some industrial components we can help you with. When projecting an imposing piece of machinery or structure, contact BaiChuan Precision, one of the largest CNC machine manufacturers globally.

Yes , we can sign the NDA before you send the drawing.

In General , For sample , it is take about 5-7 days , and for mass production, it Is take 14-20 days.

We don’t have MOQ and accept orders of any quantity.

We’d love to hear from you! Send us a message using the form opposite, or email us.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.