Everything You Need to Know About Plastic Welding

When we think about welding, the first image that likely comes to mind is the bright sparks and molten metal used to join steel or

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

When we think about welding, the first image that likely comes to mind is the bright sparks and molten metal used to join steel or

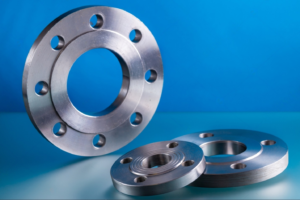

Industry systems require various components and one of them is a flange accessory. Flange accessories act as important elements in establishing strong and reliable connections

In modern production, electroplating is an essential procedure that unites durability, utility, and beauty. It is crucial in high-tech sectors including aerospace, electronics, automotive, and healthcare, and it may improve conductivity and corrosion resistance in addition to offering aesthetically pleasing surfaces.

Flange connections are essential in various industries. The choice of the appropriate method relies on considerations such as pressure, temperature, maintenance, and cost. Welded flanges are strong and reliable for systems with high pressure. Bolted flanges are easy to maintain and replace. Threaded flanges work well for low-pressure and portable setups. Lap joint flanges offer flexibility, and blind flanges are perfect for sealing systems.

Flanges are among the most important parts of piping systems, which ensure a tight and reliable joining of pipes, valves, pumps, and other pieces of equipment. Their main application is to provide tight connections with easy access for maintenance, cleaning, inspection, or modifications of a system. Flanged joints are formed by bolting two flanges together with a gasket placed between them to provide tight sealing to prevent leakage.

TIG welding, also known as GTAW, has become a universal joining method through which several major industries operate in regard to its precision and the versatility of working with it. The processes are employed to weld longitudinal seams in thin-wall stainless steel and alloy pressure pipes, and in continuous strip mills, where a lack of filler metal is often preferred. On the contrary, it also employs the presence of filler metal for thicker walled pipes and tubing in all welding positions inside the power generation, chemical, and petroleum industries.

In high-precision sectors, vacuum welding is a game-changing technique that provides unmatched advantages like excellent weld quality, little contamination, and the capacity to fuse materials that are challenging to weld under typical circumstances. Particularly in crucial applications like aerospace, electronics, medical devices, and energy systems, vacuum welding guarantees the dependability and durability of welded components by establishing a regulated, contaminant-free environment.

Flanges are critical components in industrial piping systems. Choosing the right products promotes the safety and efficiency of operations. Getting a reputable flange and accessories supplier is a possibility.

When you know how to approach the market, you can guarantee quality. Always consider the materials, sizes, dimensions, and durability. You need products that ensure safe piping and prolonged application. With this information, you can buy precision-manufactured flanges.

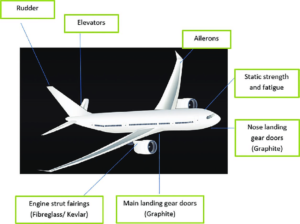

Landing gear system production certainly has shifted as an outcome of CNC machining, which provides unmatched accuracy, productivity, and flexibility to satisfy the exacting requirements of contemporary aerospace engineering. CNC machining will remain at the forefront of developing more dependable, effective, and innovative landing gear systems through continued developments.

CNC machining is revolutionizing the avionics and navigation systems sector by providing accuracy, productivity, and the capacity to work with cutting-edge materials. With the ongoing advancements in automation, artificial intelligence, and additive manufacturing, CNC technology will become increasingly essential in fulfilling the need for more intricate, high-performance, and smaller components.

The production of engine parts now relies heavily on CNC machining, which offers unparalleled accuracy, productivity, and scalability. From creating complex components like turbine blades and pistons to enabling creative solutions in lightweight and hybrid materials, CNC technology is pushing industry innovations.

Modern aerospace manufacturing relies heavily on CNC machining to overcome challenges in efficiency, material complexity, and precision. The design and manufacturing of airplane components are changing as an outcome of new trends including AI integration, hybrid machining, innovative materials, and sustainability.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.