Internal thread by cold extrusion is a CNC machining procedure for metal and plastic that creates internal threads using extrusion taps. It features high material usage, precise CNC machining, smooth surfaces, high mechanical strength, and good fatigue resistance.

The cold extrusion CNC machining technique of the internal thread was investigated in order to increase the anti-fatigue service life of the thread. The plastic deformation law and surface integrity of the metal layer during cold extrusion are summarised to increase stability and economy.

Do you want to know what is the mechanism of cold extrusion and how many factors influence the internal threads formations?

In this blog, we will discuss all this in detail. So, Let’s get straight into it.

Cold extrusion CNC Machining

Internal thread processing has slowly evolved into a trend that uses the cold extrusion method instead of chip processing. It has significant fatigue resistance because the internal thread, which was extruded using the metal-plastic forming method, has a superior surface quality, high hardness, and strength.

If the process parameters are not appropriately chosen, the internal thread extrusion formation will result in increased extrusion torque, excessive extrusion temperature, or even tap failure.

The extrusion tap must endure a significant amount of extrusion torque during the cold extrusion of internal threads in order to overcome the resistance of metal plastic deformation.

The extrusion temperature will increase significantly as a result of the significant quantity of frictional heat produced in the area of contact between the workpiece and the extrusion tap.

Both have a significant impact on the thread formation quality and the service life of extrusion taps. The process parameters, the extrusion torque, and the resulting extrusion temperature are all variable while processing various types of threads.

It’s crucial to foresee the relationship between process parameters and extrusion quality in order to assure the extrusion quality and the efficient implementation of the extrusion process.

Mechanism of The Internal Thread Cold Extrusion

Extrusion of internal threads differs from conventional cutting and tapping. Cold-extruded threads have an identical lifespan of 4-30 times of cutting threads under identical conditions. Extrusion taps are used in this metal plastic processing technique to create a tooth profile.

A constrained area is used to carry out the plastic deformation of the metal when the tap extrudes the material. After multiple extrusion cycles, an internal thread is created by cyclically compressing the metal in the deformation zone. According to the size of the thread that will be extruded, a hole of a specific size is prepared on the workpiece, as seen in Figure 1a.

The hole serves as a starting point and coordinates the axial feed and rotation of the tap. Intermittent contact between the workpiece and the tap’s teeth is observed. The metal accumulates and grows as it travels along the tap’s ridge.

The squeezed part is completely unloaded when the tap removes the workpiece, and the elastic deformation returns, the plastic deformation persists, and finally a thread profile is generated.

Influencing factors

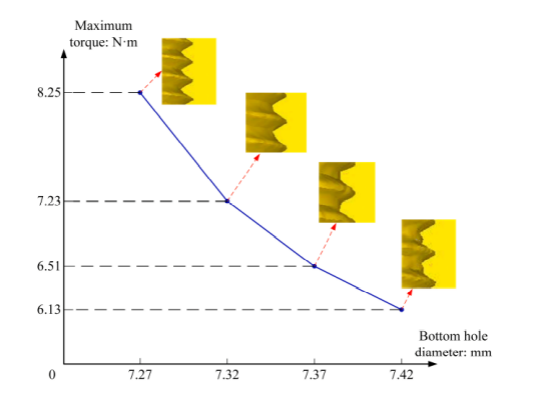

(1)Dimensions of the lowest Hole

The size of the bottom hole controls both the operating torque and how full the tooth form is. When the bottom hole is very large, the tooth profile is unclear but the torque is moderate. Conversely, when the bottom hole is relatively tiny, the tooth profile is full but the torque is significant after extrusion.

(2) Speed of extrusion.

Four speeds of 15 r/min, 30 r/min, 45 r/min, and 60 r/min were chosen for simulation in order to evaluate the effect of extrusion speed on working torque and extrusion temperature, and the effect of extrusion speed on torque and workpiece temperature was obtained. The following figure depicts the law of influence.

(3) Factor of Friction

Strong friction between the tap and the surface of the workpiece during the extrusion of the internal thread causes the metal to be plastically deformed, which will result in significant heat production.

Reduce friction between the workpiece and the tap, lower the operating torque of the extrusion, and lengthen the life of the extrusion tap by effectively cooling and lubricating the extrusion deformation zone.

Benefits of Cold Extrusion Internal Thread

1) Preserve Basic Materials: Cold extrusion of metal with an internal thread is bent into the desired shape by CNC machining. It uses CNC machining without cutting. It can greatly increase the rate of material usage.

(2) Increase internal thread CNC machining Accuracy: The interior thread of the cold extrusion has very little shape and positioning imperfection. The accuracy of 4H 5H is simple to obtain for common materials.

(3) The optimal level of surface wear. The thread-forming tap’s teeth press against the thread surface during the extrusion process. The cold-extruded internal thread’s surface roughness can be as high as Ra0.40.8.

4) Increase the internal thread’s mechanical toughness: A reasonable streamline distribution is generated along the thread shape after the internal thread is cold extruded, the surface metal is cold hardened, and the surface structure fiber is refined.

(5) Increase the effectiveness of internal thread CNC machining: Production efficiency will be significantly increased by producing internal thread parts using cold extrusion technology rather than other CNC machining techniques.

(6) It is appropriate for CNC machining of blind and deep hole threads: The internal thread cold extrusion process does not require chip cleaning, reducing or eliminating the risk of tooth or thread tap fracture brought on by the challenge of chip removal.

(7) Lower the cost of manufacturing: The internal thread cold extrusion CNC machining technique offers the advantages of minimizing the volume of parts that need to be CNC machined, boosting production efficiency, and saving raw materials. It can significantly cut the cost of internal thread parts by substituting lower-grade materials for high-quality ones.

Challenges of Cold Extrusion Internal Threads

(1) Thread-forming taps are in heavy demand.

The thread-forming tap significantly increases its deformation resistance by supporting three-dimensional compressive stress during the cold extrusion process of the internal thread. Compared to other internal threading techniques, thread-producing taps have significantly more stress. This necessitates that thread-forming taps have high strength as well as adequate impact toughness and wear resistance. Thread-forming taps typically have a minimum service life due to phenomena.

(2) Costly & complex production

Thread forming taps are expensive and need a complex manufacturing process. It is typically only appropriate for internally threaded items used in mass production.

(3) Not Suitable for all purposes

It is inadequate for CNC machining of high-strength and brittle materials. It is not appropriate for CNC machining threaded holes with inclined grooves, holes with missing threads, or holes with thin walls.

(4) Insufficient impact strength

The cold extrusion internal thread’s plasticity and impact toughness are inadequate. The surface has significant residual stress, which makes it simple for the interior thread to deform.

(5) Surface Lubrication

The cold extrusion of internal threads has robust control on the bottom hole of the product in addition to the relatively large feature precision; surface lubrication of the workpiece is also necessary prior to cold extrusion.

Applications

The cold extrusion method is frequently used to fabricate products made of zirconium, lead, tin, titanium, molybdenum, vanadium, steel, copper, lead, and aluminum alloys. Various parts, such as Collapsible Tubes, Gear Blanks, Aluminum Cans, Cylinders, Fire Extinguisher Cases, Shock Absorber Cylinders, and Automotive Pistons, are some of the products that are created using this procedure.

It offers a wide range of potential applications in aviation, aerospace, high-speed train, and other industries.

In the automobile industry, cold extrusion is also employed in a number of the applications listed below:

- automatic gearboxes.

- seat engineering.

- safety measures (restraint systems).

- injection technology.

- engine maintenance.

- supply of fuel.

Conclusion

The use of cold extrusion to create internal thread mesh has grown in importance in anti-fatigue CNC machining as internal thread CNC machining has evolved toward high performance, low cost, and low energy consumption. It has numerous potential uses in the sectors of aviation, aerospace, high-speed railways, and other things.

According to the findings, cold-extruded internal threads perform much better under fatigue than cutting threads. Cold-extruded threads have an identical lifespan of 4-30 times; of

cutting threads under identical conditions.

Do you have anything else to know about this blog? Leave your comment below.