In manufacturing industry, the product is often shaped and put together with tools made of steel. Such tools range from the familiar and unspecialized, such as drills and screwdrivers, to more specialized equipment such as dies for casting molten metal or for forming such parts as the panels of automobiles (in engineering, forming means forging or stamping). There are many kinds of tool steel. Tool steel for cutting metal is normally chosen from a family called the high-speed steels (HSS), which bear that name because they remain hard and wear-resistant up to as much as 600 degrees Celsius (C). HSS can cut metals at high speeds compared to tools of more ordinary steel, which would begin to soften above 200 degrees C, approximately. A similar distinction exists among the sorts of steels that are used to cast or form metal. In those operations, engineers speak of hot work tool steel and cold work tool steel. Hot work tool steel is used for dies that hold molten metals such as aluminium and zinc in place until the liquid solidifies, or for forming metal above 200 degrees C (approx.), while cold work tool steel is used to form metal below the same temperature.

Introduction

In manufacturing industry, the terms ‘tool’ and ‘tool steel’ have a special technical meaning. They are used to describe a part of the manufacturing machinery that comes in contact with the product, and the steel that this part is made from, if it is made from steel (as it usually is).

Tools, so defined, may be used for the purposes of cutting, casting, or forming.

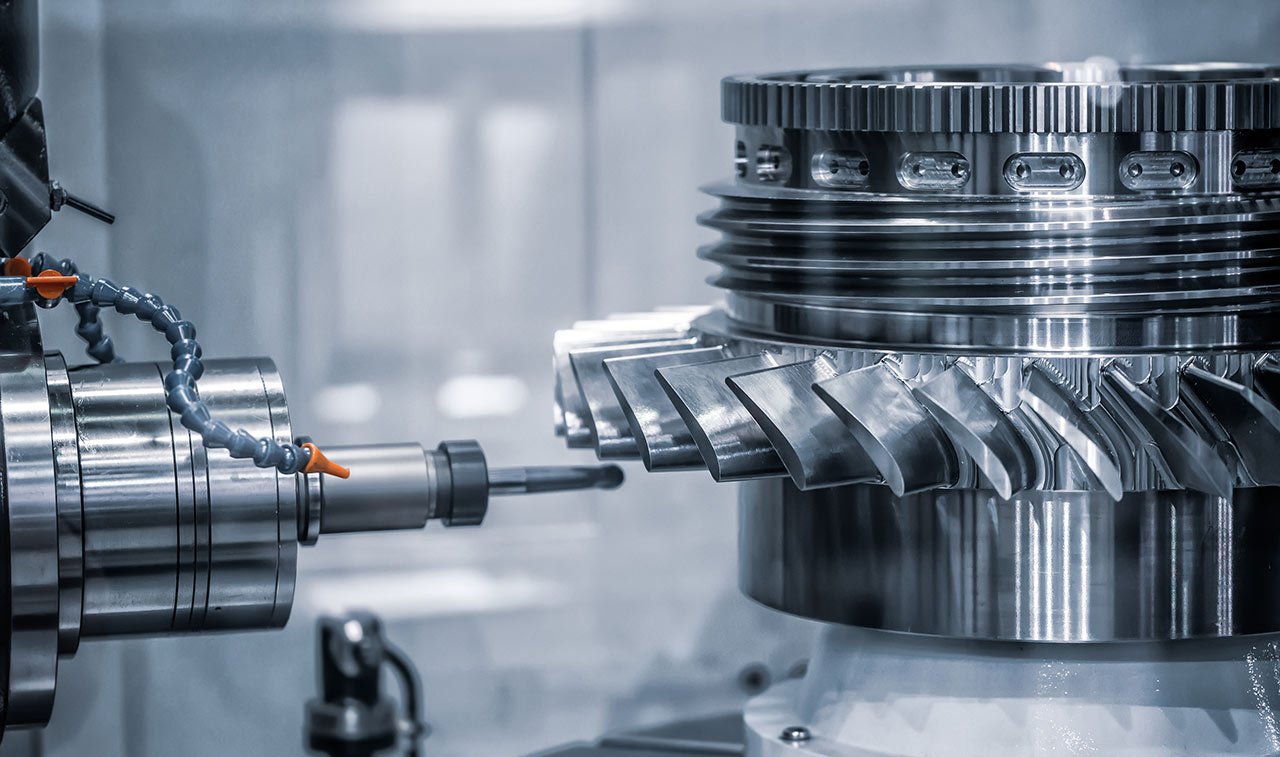

Cutting is the action performed by a drill, or the single-point tool on a lathe. It is also the action performed by the multi-point tooling of a milling machine or a saw blade.

Casting is the action of holding molten metal, or any other molten material, in place until it solidifies.

Forming is the action of forging, bending, or stamping a solid workpiece, such that its shape is changed without loss of material.

Sometimes these actions are combined, for example, when a press cuts a circle in a sheet of metal and simultaneously forms it into the base of a saucepan.

In this technical usage, the machine that holds the tool, and the materials that the machine that holds the tool are made from, are generally referred to separately from the tool itself.

The History of Tool Steels

The very first tool steels were probably those used to make traditional instruments such as hammers, anvils, knives and axes. This were hardly distinguishable from ordinary iron made by the most primitive techniques, at first.

But with the passage of time, traditional blacksmiths learned to alter the properties of iron in order to make it harder for some uses, and tougher for others. These modified forms of iron became the first true forms of steel.

In the early days of steelmaking, more than three thousand years ago, smiths discovered that by heating up iron of a certain composition and then plunging it into oil or water, it could be made harder than if it was simply allowed to cool down naturally. By “a certain composition,” I mean iron that contained roughly one per cent by weight, or so, of dissolved carbon when it was in the hot condition. Sudden quenching would prevent the carbon from coming out of solution to form comparatively large particles of iron carbide in a matrix of relatively pure and soft iron. Instead, the quenching process locked the carbon atoms in place in what was now a strained matrix of iron and carbon called martensite, which is more difficult to deform.

Of course, all this chemistry was not known at the time. Instead, the smiths of yore worked by various rules of thumb. In the English language, this gives rise to the expression “black art.” The work of the smiths was an art rather than a science, it was grimy and black in physical terms, and on top of that nobody really knew what the smiths were doing. Were they in league with demons from the similarly fiery pit of Hell? For all these reasons, the work of the smith was known as the ‘black art’, a term that is applied to any other similarly mysterious process today.

Public domain image of a traditional blacksmith (1606 CE) via Wikimedia Commons

Over time, the art of the smiths became more elaborate and skilled, though still an art. Pieces of the very hardest steel would be placed where the edge of a blade would be and combined with pieces of softer but tougher steel to form the bulk of the blade. Another method of initial preparation involved the precipitation of carbide dendrites in a single block of steel. However, it arose initially, the composite would then be beaten, heated and folded many times to disrupt potentially embrittling impurities and gas bubbles, and to form blades with tough bodies and hard edges. These techniques, which by name included the Japanese mokume-gane method and the Middle Eastern Damascus method, produced steel with swirling patterns that revealed the underlying structure, especially when etched. Still, there was little scientific understanding of what was really going on, as opposed to a more intuitive and artistic understanding.

A Japanese sword made by the mokume-gane technique on a background of chain mail. Photograph by ‘Dafannin’, 12 May 1986, CC BY-SA 4.0 via Wikimedia Commons.

Things became more scientific in the late 1700s and early 1800s. The emergence of modern chemistry made it clear that the steel of the time was an alloy, indeed a composite, of iron and other elements; that the main additive was carbon; and that the carbon took different forms in soft steel, hard steel, and cast iron (where the concentration of carbon was about four per cent by weight).

By increasing the proportion of carbon in the steel in a controlled manner, it became possible to produce extra-hard, though somewhat brittle, steels which were good for cutting other forms of steel. The first tool steels of a modern type were thus born.

These early tool steels combined a mostly martensite (quench-hardened) matrix with additional inclusions of iron carbide.

However, they suffered the drawback of tending to soften above 200 degrees Celsius, and this limited the rate at which they could be used to cut other steels.

In 1868, the Scottish engineer Robert Mushet, himself the son of one of the first ironmasters to recognize the importance of carbon, came up with a form of steel that remained hard at higher temperatures.

Known as Mushet steel, the new alloy contained not only the usual amounts of carbon but still larger amounts of manganese and tungsten. Mushet steel also had the unusual property of not needing to be quenched in a liquid. It was the first ‘air hardening’ steel: a steel that hardened to martensite-like levels simply by cooling down from red heat in a jet of air.

In the early 1900s, the properties of Mushet steel were improved still further by the American engineer Frederick Winslow Taylor, and his colleagues. The result came to be known as high-speed steel (HSS). HSS remains usefully hard right up to 500 or even 600 degrees Celsius: whence its name, as it can be used to cut other steels at even higher speeds than Mushet steel. Along with the iron and carbon that are common to all types of steel, most HSS alloys continue to include large amounts of tungsten, plus chromium, which has replaced the manganese of the initial Mushet formulation.

These days, carbide tips are often used for the most demanding metal-cutting applications, though high-speed steels remain the preferred material for the manufacture of saw blades and twist drill bits, for which the insertion of carbide tips would normally be impractical, especially in the smaller diameters and finer tooth size grades.

But what about Casting and Forming?

Up to now, I have described improvements in tool steels that are used for cutting things, from early blades through to modern HSS industrial tools. However, the modern distinction between cold work tool steel and hot work tool steel really applies to steels that are used for casting and forming.

Hot work steels are used for processes where the temperature of the tool will exceed 200 degrees Celsius (392 degrees Fahrenheit).

Cold work tool steels are used for processes where the temperature of the tool remains below 200 degrees Celsius.

The 200 degrees Celsius dividing line is not absolutely hard and fast, given that there are many different alloys with different properties, but it is a conventional dividing line that is widely referred to in the literature.

With all forms of tool steel, the main causes of failure are breakage, deformation (especially permanent or ‘plastic’ deformation), surface wear, and the development of surface fatigue cracks caused by cyclic stresses. Cyclic stresses are both mechanical and thermal in origin; thermal stresses are an especially serious issue for hot work tool steels.

Cold Work Tool Steels

Cold work tool steels are generally high-carbon steels, typically containing around one to one and a half per cent carbon by weight. The most common types are oil hardening low-alloy grades, air hardening medium alloy grades, and high-carbon high-chromium grades.

Oil-hardening low-alloy grades are the cheapest. Save for the fact that they contain fewer impurities, they are otherwise much the same as the old-fashioned forms of tool steel that were used prior to Mushet steel.

Air hardening medium alloy grades harden with less distortion than steels that have to be quenched. They can also be hardened in thicker sections than oil-quenched steel, up to 100 millimetres or more.

High carbon high-chromium grades, which are hardened either by oil quenching or air hardening depending on their exact composition, are the most wear-resistant.

Cold work tool steels are typically used for a multitude of everyday industrial uses, including:

- Die casting of plastics

- Dies for shaping thin metal panels such as the curved body panels of automobiles

- Lathe chucks and centres

- Rollers

- Roll forming dies for screw threads and knurling

- Broaches, reamers, taps and mandrels

- Wheels and holders working of wire and cold tubes

- Shears, blades and other cutting tools, for applications where the cutting is brief and little heat will be generated

- Gauges

- Blanking, drawing and piercing dies

Hot Work Tool Steels

Like Mushet steel and the earliest high-speed steels, hot work tool steels have traditionally included large amounts of tungsten as an alloying element. However, there are also hot work tool steels that have chromium as the main alloying element, and other grades that have molybdenum as the main alloying element.

Along with high-speed metal cutting and drilling, hot work tool steels are typically used for:

- Die casting of metals

- Extrusion

- Forging

- Manufacturing of glass products

Materials Selection for Casting

Casting processes for which tool steel are used are called die-casting, in which the tool serves as a die, imparting a detailed or comparatively precise shape to the final article in ways that are more faithful, and repeatable, than is possible with casting in sand molds.

Die casting probably originated with the casting of letters for moveable type in the 1400s CE, in open dies in the shape of each letter. In In the modern sense, the metal is injected under pressure into a mold made of two opposing tools, which it fills precisely.

Die tooling for plastics is commonly made from special grades of cold work steel known as P steels, from aluminium, or from beryllium-copper alloys. The advantages of copper and aluminium, for this use, include much higher thermal conductivity and consequently faster and more even cooling than steel.

On the other hand, steel molds last longer (up to millions of cycles) and can better resist erosion by jets of fast-moving plastic, especially if it contains abrasive composite reinforcement such as glass fibre. Some surface finishes can only be reliably achieved with steel, as well.

Materials Selection for Forming Processes

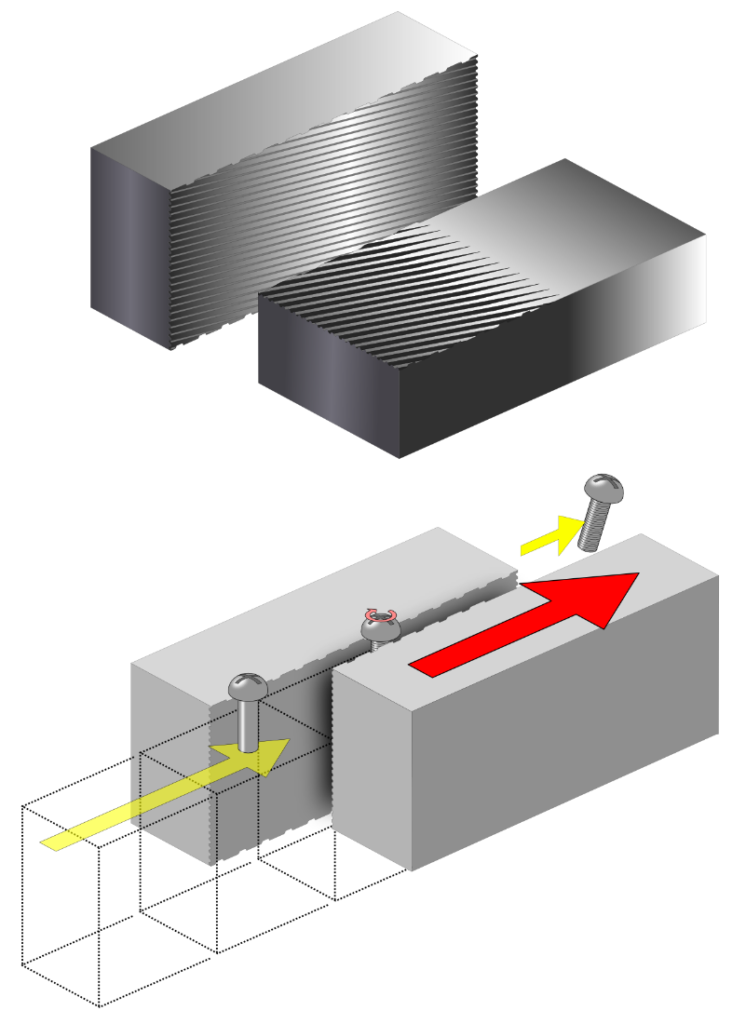

Metal forming processes for which cold work tool steel are used generally do not involve a very high degree of bulk deformation of the metal. The imparting of screw threads to the surface of a rod by rolling, or the pressing of a flat sheet of metal into the complex curves of an automobile body panel, are typical of cold forming processes in that sense.

Cold roll forming of a screw thread. Graphic by ‘Tosaka’, 12 October 2009, CC BY 3.0 via Wikimedia Commons.

Cold work processes often impart some improvements to the quality of the metal through reorientation of the metal’s crystalline structure and work hardening, though the effect on the crystal structure is usually confined to the surface and less dramatic than in the case of forging, which I discuss in the next section.

All of the more drastic processes of metal forming involve hot work (above 200 degrees Celsius). As noted, these include:

- Extrusion, and

- Forging

As we have also mentioned, the making of glass articles is another major application for hot work tool steel.

Extrusion is the process by which a warmed and softened material is pushed through a die to form a long article of constant cross-sectional profile. The most familiar examples of extruded articles are plastic and aluminium sections, which can have quite complicated shapes. Plastic sections can be extruded through cold work tool steel dies, but aluminium sections must be extruded through hot work tool steel dies.

A special category of extrusion is upset extrusion, used to form such things as the bodies of aluminium cans and pill tubes. With upset extrusion, a die is pushed down into a blank piece of metal which then flows backward around the die to form the can or the tube. It is truly remarkable that cans and tubes with such thin, yet even, walls can be formed by this method.

Seamless tubes are also manufactured by extrusion. A solid billet is heated and then pierced in the middle. It is then placed over a mandrel and given its final size and wall thickness by extrusion.

Forging is the process by which a piece of hot metal, often red-hot, is pounded into its final shape by an industrial hammer, with only minor machining (cutting) operations to follow. A good example of a product that is usually made by forging is a spanner. The hammer may be mechanically driven in both directions, or it may be lifted mechanically and dropped by gravity (‘drop forging’).

Forging steel tyres for railway train wheels. Photo by Rainer Halama, 19 June 2010, CC BY-SA 3.0 via Wikimedia Commons.

Forging is a direct industrial descendent of older smithing techniques such as mokume-gane and Damascus. It has a similar effect, namely, that of causing glassy impurities and gas bubbles to be dispersed and closed up, and the large crystals or ‘grains’ that are usually found inside as-cast metal – similar to the spangles on a galvanized iron fence, themselves a type of metal crystal – to be disrupted and replaced by smaller ones and, in many cases also, to be deformed in the direction of the outside curves of the final shape.

As one might expect, a fine grain structure is superior to a coarse one; and a fine grain structure in which the grains also follow the shape of the product improves the mechanical properties of the final article still further, making it far less likely that the article will crack at a corner under heavy loads than otherwise.

There is a very good illustration of shape-following crystals on the website of dropforging.net. The essential similarity to the products of the most highly skilled smiths of earlier times are evident, except that in this case the result is an industrial article rather than a sword.

Many of the most ‘serious’ mechanical articles, items that bear heavy loads and would have grave or at least highly annoying consequences if they were to break, are forged. Along with spanners, which might snap at the points of maximum stress, near the nut, if they were made by any other method, forged articles include the crankshafts of engines and the connecting rods that join the pistons to the crankshaft, although the pistons themselves are usually cast. (Forged pistons are, however, used in racing engines and are becoming increasingly popular in general use).

There are two main kinds of forging: open forging and closed-die forging. Open forging pounds metal into a rough shape and improves its general interior structure but does not otherwise impart any particularly definite shape or grain pattern. Closed-die forging produces more definite shapes and grain patterns.