Delivering precision-engineered components with uncompromising quality standards, rapid turnaround times, and scalable production capacity. Your trusted partner for critical industrial spare parts that perform when it matters most.

Precision-engineered spare parts across multiple materials with 20+ years of expertise, 30 CNC machines, and fast turnaround capabilities for global industrial markets.

Established in 2000, Baichuan Precision Parts is located in Kunshan City. 40 KM from Shanghai, 30 mins drive time/12 mins high-speed railway.

10000 square meters machine shop, equipped with more than 30 cnc machines, including large vertical gantry Mills, work range 6500*4200*1800mm.

High precision inspection equipment including CMM, profile projectors, etc. Checking tolerance is +-0.0005mm.

Technology team with more than 40 years of experience, offers cost-effective solutions.

Expert engineering support to optimize designs for manufacturability and performance

Fast turnaround from concept to production samples for validation and testing

Seamless transition from small batch to high-volume manufacturing without compromising quality

Precision-engineered components tailored to your specific industry requirements and performance demands.

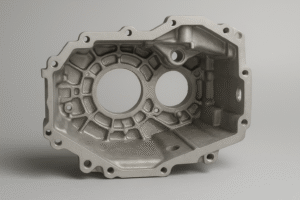

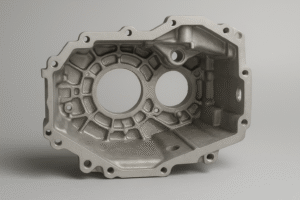

Precision-machined aluminum or high-strength steel transmission housings with tolerances controlled within ±0.025mm, ensuring precise gear engagement. The inner cavities undergo special treatment to withstand high temperatures and oil corrosion, with 5-axis CNC machining guaranteeing perfect execution of complex internal structures for both automatic and manual transmission systems.

Precision-machined aluminum or titanium alloy mast connectors and rigging components with load capacities up to 50 tons. Anti-corrosion anodized finishes with all load-bearing points controlled to ±0.05mm tolerance, ensuring navigational safety and structural durability suitable for extreme marine environments.

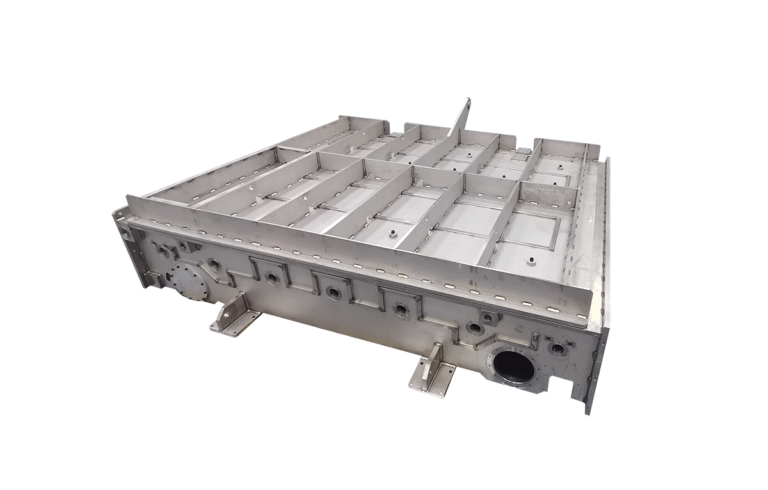

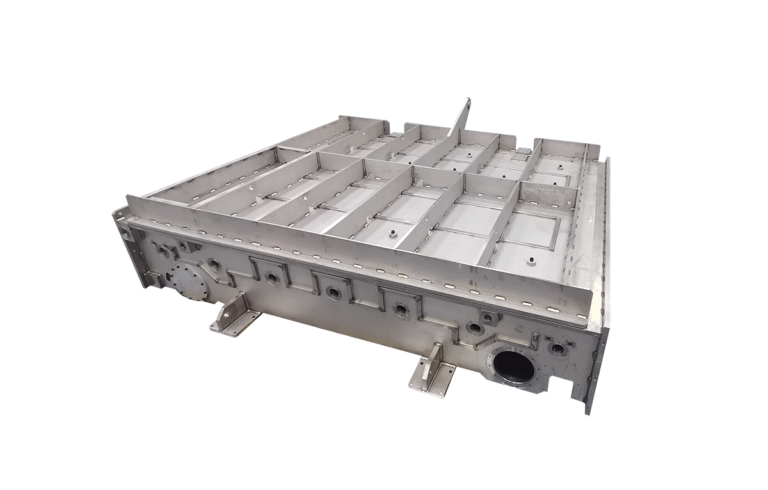

Manufactured from high-purity 304L/316L stainless steel or aluminum alloys with internal surface roughness Ra≤0.4μm and vacuum sealing performance reaching 10^-9 Pa·m³/s levels. Electropolished interior walls minimize gas release, with maximum processing dimensions of 6.5m×4.2m×1.8m, suitable for high-vacuum process equipment including PVD and PECVD systems.

Lightweight structural components manufactured from aerospace-grade aluminum or titanium alloys, utilizing 5-axis machining centers for complex curved surfaces with wall thickness tolerances controlled within ±0.05mm. All hole features employ helical milling techniques, increasing fatigue strength by 30%, with full material traceability reports and stress-relief certification for all products.

High-density tungsten alloy collimators and detector frames manufactured using 5-axis machining technology to achieve complex internal structures. Detector array positioning precision of ±0.005mm ensures high-resolution imaging. Rotation ring bearing housings made from special aluminum alloys with G0.4 dynamic balancing precision, maintaining stable performance at high rotation speeds of 4 revolutions per second, extending equipment service life.

Delivering precision-engineered components with uncompromising quality standards, rapid turnaround times, and scalable production capacity. Your trusted partner for critical industrial spare parts that perform when it matters most.

Precision-engineered spare parts across multiple materials with 20+ years of expertise, 30 CNC machines, and fast turnaround capabilities for global industrial markets.

Established in 2000, Baichuan Precision Parts is located in Kunshan City. 40 KM from Shanghai, 30 mins drive time/12 mins high-speed railway.

10000 square meters machine shop, equipped with more than 30 cnc machines, including large vertical gantry Mills, work range 6500*4200*1800mm.

High precision inspection equipment including CMM, profile projectors, etc. Checking tolerance is +-0.0005mm.

Technology team with more than 40 years of experience, offers cost-effective solutions.

Expert engineering support to optimize designs for manufacturability and performance

Fast turnaround from concept to production samples for validation and testing

Seamless transition from small batch to high-volume manufacturing without compromising quality

Precision-engineered components tailored to your specific industry requirements and performance demands.

Precision-machined aluminum or high-strength steel transmission housings with tolerances controlled within ±0.025mm, ensuring precise gear engagement. The inner cavities undergo special treatment to withstand high temperatures and oil corrosion, with 5-axis CNC machining guaranteeing perfect execution of complex internal structures for both automatic and manual transmission systems.

Precision-machined aluminum or titanium alloy mast connectors and rigging components with load capacities up to 50 tons. Anti-corrosion anodized finishes with all load-bearing points controlled to ±0.05mm tolerance, ensuring navigational safety and structural durability suitable for extreme marine environments.

Manufactured from high-purity 304L/316L stainless steel or aluminum alloys with internal surface roughness Ra≤0.4μm and vacuum sealing performance reaching 10^-9 Pa·m³/s levels. Electropolished interior walls minimize gas release, with maximum processing dimensions of 6.5m×4.2m×1.8m, suitable for high-vacuum process equipment including PVD and PECVD systems.

Lightweight structural components manufactured from aerospace-grade aluminum or titanium alloys, utilizing 5-axis machining centers for complex curved surfaces with wall thickness tolerances controlled within ±0.05mm. All hole features employ helical milling techniques, increasing fatigue strength by 30%, with full material traceability reports and stress-relief certification for all products.

High-density tungsten alloy collimators and detector frames manufactured using 5-axis machining technology to achieve complex internal structures. Detector array positioning precision of ±0.005mm ensures high-resolution imaging. Rotation ring bearing housings made from special aluminum alloys with G0.4 dynamic balancing precision, maintaining stable performance at high rotation speeds of 4 revolutions per second, extending equipment service life.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.