The most adaptable machining technique used in the manufacturing sector is sheet metal fabrication. From automobiles to the highly precise aerospace industry, this process is used in nearly all relevant mechanical fields. Sheet metal fabrication is ubiquitous. When making durable components like panels, brackets, conical structures, and related niches, it is best suited.

I'll sum up all the methods for fabricating sheet metal in this article, such as cutting and bending, but first, it's important to understand what sheet metal fabrication is actually all about.

What is sheet metal fabrication?

It is a process to convert metal sheets into functional parts, different mechanical operations like cutting, bending, folding, and assembling are performed to get the desired shape. This process includes a wide range of materials ranging from aluminum, copper, stainless steel, high carbon sheets, brass, and other similar materials. It is a quite simple technique, and most manufacturers prefer to construct a 3D model before carrying out mechanical operations. A detailed model shows every little nuance of the finished product. The required shape is then manufactured and the machining operations are completed.

The manufacturers implement various techniques to apply these mechanical processes. some prefer to use laser cutting however some go with water Jet or plasma cutting. Every process comes with its own pros and cons. For sheet metal fabrication, a thickness of 0.006 to 0.25 inches is ideal. Depending on the specifications of the product, the manufacturers may use a variety of techniques or combinations of them. Cutting, joining, bending, forming, and finishing are the fundamental operations.

Sheet Metal Cutting Techniques:

One of the frequently used machining techniques in the sector is sheet metal cutting, which involves applying intense pressure to the sheets until the cutting edges fail and surpass the ultimate tensile strength of the material. Electronic cutters or CNC machines are also used in this process.

But when dealing in bulk quantities or for large manufacturing batches, the Machinist prefers to use plasma, laser, or water jet cutting processes, as they ensure precise machining and high efficiency. We will briefly go over the procedure here.

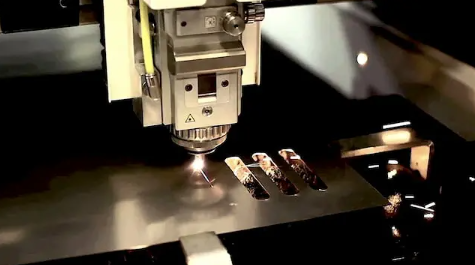

Laser Cutting:

Laser cutting is a thermal cutting process, it involves a highly focused laser beam directed through optics and a computer numerical control unit. Typically the process follows a CNC or a G-code pattern that is used to cut the material. The highly focused laser beam, melt, vapourize and cut the material as per the desired shapes given to it.

As per the cutting material and beam applications, the laser beam alters its focal length and is good for deep cuts and cavities, due to its pinpoint accuracy, laser beam cutting is widely used for engraving and medical purposes. At its narrowest point, a laser beam is typically under 0.0125 inches (0.32 mm) in diameter.

The laser cutting technique is ideal for industrial machining, as it provides good precision, time efficiency, and work flexibility. This technique is applicable to a wide range of materials ranging from metals to nonmetals. However special arrangements are needed as per the desired materials, specifically, if you are dealing with soft or reflective metals, the surface of the reflective metals bounces back the laser beam, which may damage the machinery, however, fiber optic laser machines are perfect for those, metals such as aluminum, silver, copper, and gold are all reflective material and are widely used in the production of automobiles and semiconductors.

The thickness of sheets is also an important factor when you are dealing with cutting techniques, laser cutting is suitable for sheet thickness ranging from 0.5mm to 12mm, but it depends upon the material and its surface properties. If you desire to treat more thick sheets you need more powered laser beams. As laser beams require a specific setup, highly processed gasses, high energy consumption, and safety precautions make them a costly process, so it is used where precision, bulk quantity, and time efficiency are the priority factors.

Plasma Cutting:

Plasma cutting uses ionized gasses to cut the sheets of metals, the process includes a high electrical stream of highly ionized gasses which forms a hot flame of plasma that can easily cut the sheet metals. The plasma melts the targeted area, resulting in a blurrier surface because it includes thermal processes, and it will oxidize the surface near the cutting zone.

Plasma cutting is used where we need to cut thick metal sheets, specifically ranging from 50mm and above. They are ideal for machine reflexive materials, like copper, aluminum, and brass and they are ideal for the cutting of high-strength metals with low heat input, which makes them best for high-carbon steel sheets. They are not as precise as laser and water jet cutting and also make the cutting area oxidized, furthermore another drawback of using this technique is high power consumption, for these issues plasma cutting is not preferable for small industries.

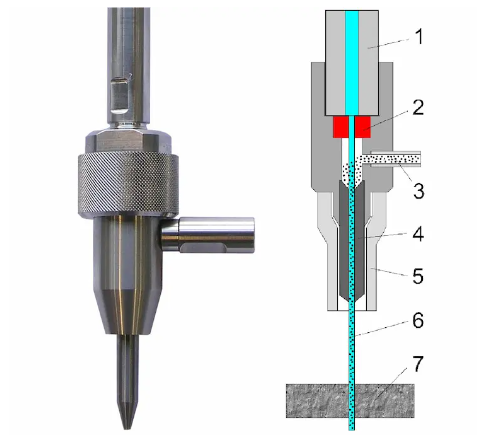

Waterjet Cutting:

The third and the most economical technique for sheet metal cutting is water jet cutting. The mechanism includes a high-pressure water stream ranging from 60000 PSI to 75000 PSI to cut the metal sheets into desired shapes. The water jet cutting is famous for its precision, time efficiency, and economical mechanism. Moreover, it also ensures high surface finishing and it does not even create blurs, like the plasma cutting process.

Water jet cutting is mostly used where we need to cut soft materials like rubber, metal foils, and fabrics, if we need to implement it on thick metal sheets then abrasive water jet cutting is used, through abrasive water jet cutting we can cut, stainless steel, high carbon steel, aluminum, and brass.

The operating mechanism of the water jet cutting is the same as the above two and the encoded message is saved in its control unit to operate the water jet nozzle. The code decides the final shape of your end product.

Blanking:

Blanking is another well-known sheet metal cutting process in the manufacturing industry. It employs a punch and dies mechanism for cutting sheet metal. The die is created in accordance with the desired end product. To cut the desired shapes, the blanking force is applied to it. The material left behind is the required product, whereas the cutting done by the blanking force is waste.

Blanking insurance precise cutting, dimensional control, Lean manufacturing, and smooth fabrication, one drawback of using this technique is that it is a time-consuming process and needs good mechanical equipment which makes it costly process than ordinary punching, however, if we talk about accuracy and precision it is far better than punching. The best material on which the blanking process can be applied is high carbon steel, aluminum, and copper sheets. compound die stamping, progressive die stamping, and continuous strip blanking are some of the famous blanking techniques which are implemented as per the required conditions.

Punching:

Punching also includes a punch and die mechanism, it is mostly used for making holes in metal sheets, A metal sheet is placed above the die, and a punch is applied on it forcefully, which passes the sheet and makes the desired cutting shape due to shearing effect produced in the sheets. The main difference between these two techniques is that in bending the sheet metal piece left on the die is a waste while the other sheet part is the main product we need to produce. However, punching the cutting piece on the die is the product we need to produce.

Punching is a cheap, economical, and less time-consuming process, that’s why it is mostly used in small industries . as this process does not involve any mechanical or electrical involvement so it does not leave any thermal effect on the sheet. It is used for a wide range of metal sheets, specifically stainless steel, aluminum, brass, vulcanized fibers, papers, and copper sheets. This process is mostly used where we need to fabricate thin metal sheets, ranging up to 15mm and for sheets having thickness more than that we need to increase the pressure implemented by the punch, and for that cause different machines have different punch pressures are used.

Bending:

Bending is a process that is used to deform metals into the desired shapes. Pressure is applied on the metal by using specific dyes, when the pressure increases the yield strength point of the material which is needed to bend, it deforms it at a specific angle without showing any breakage or internal stress.

The bending process is quite simple and a brake punch mechanism is used for this purpose, pressure is applied on the desired sheet by using specific dyes or rollers to bend it at a specific angle. Bending looks quite simple, but it has a lot of complexities in it. Different types of punch dies and rollers are used for a wide range of materials, and every material needs specific attention for the process.

There are various sheet metal methods, and the most common ones include

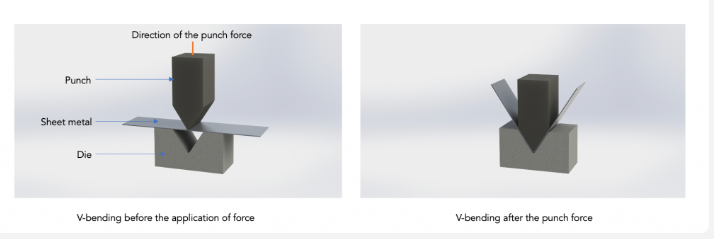

V-bending:

V-shape bending is the most common type of sheet bending, as its name implies it includes a V-shape die and a punch which are used to bend them at acute obtuse or at a right angle.

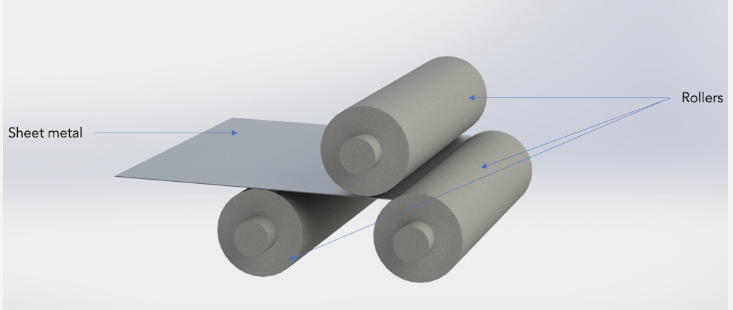

Roll bending:

Roll bending is used where we need fabrication, dyes, cones, and similar structures, its mechanism consists of three roller bars and a brake punch mechanism and it can bend sheets at various angles as per the forces applied. Roll bending is mostly used where we need to fabricate sheets of thicknesses ranging between 0.004 inches and 0.125 inches and of thicknesses up to 25mm. They find a wide range of applications in the HVAC and processing industry.

U-bending:

The mechanism of U-bending is similar to per V-bending technique, the only difference between these two is the shape of the die, it uses U-shape die for punching hence the final product is as per the die shape.

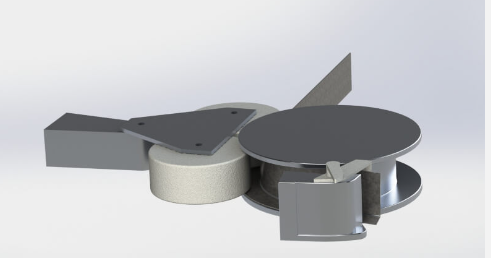

Rotary bending:

In rotary bending, we clamped the sheet metals with a rotating dye, and the metal bend as per the angle of the set dye. The radius of the final product matches the radius of the set of dies used for bending. The rotary die is quite popular in sheet metal fabrication as it does not leave any surface marks on the sheets just like V-shape and U-shape bending. Further, they are ideal for making obtuse angles and smooth corner finishing.

Bending is ideal when you are dealing with soft and malleable materials. As the pressure is implemented on a specific area so ductile materials are not suitable for bending operations. Ideal materials for bending are mild and spring steel, aluminum 5052, and copper. Materials like aluminum 6061, brass, bronze, and titanium are more difficult to bend.

Rolling:

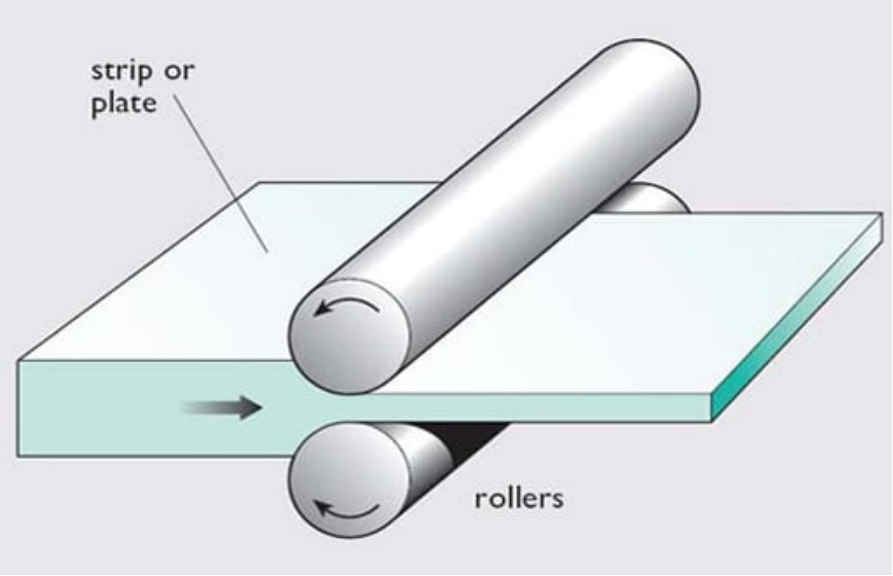

In order to reduce the thickness of metal sheets, rolling is a process in which the sheets are passed through a specific set of rollers. The rollers are set to rotate in opposite directions while the metal sheets are passed through them. If the rollers are placed at a right angle to each other, flattering may occur, so the rollers' position is slightly angled for a smooth process.

In industry two types of rolling practices are performed are usually performed which are known as cold rolling and hot rolling is done above the recrystallization temperature of the material so that new grains can easily be performed. Whereas hot cold rolling is done below the recrystallization temperature. Rolling is a cheap and time-saving process and it does not cause internal stress on the material. Rolling mills are divided as per the number and arrangement of the rolling bars, and they are classified as

- Two-High Rolling Mill

- Three-High Rolling Mill

- Four-High Rolling Mill

Baichuan is one of the leading Sheet metal fabrication industries across Asia, we are able to provide the best fabrication services with a range of mechanical processes available ranging from bending, Punching, riveting, Rolling, and finishing. Our sheet metal fabrication services along with the CNC machining services provide you with an all-encompassing manufacturing solution.