Introduction

The energy sector, which continually powers all of our technology and industry, is vital to contemporary civilization. In order to produce energy continuously and diligently, a variety of cutting-edge machinery is needed, such as hydraulic valves for the oil and gas sector, solar cells, and wind turbine components. The development of these sophisticated gadgets requires the use of CNC.

One of the main applications for CNC machining, outside aerospace and automotive, is the energy industry. The energy sector, however, is at a crossroads where it may need to accommodate cleaner, more modern energy sources alongside traditional energy sources or (more extreme) completely give up on fossil fuels in favor of renewables. From 2007 to 2017, the renewables industry increased by 5% year, helped by an increase in projects and expanding support on a worldwide scale.

The quality and effectiveness of the tools and parts used in power generation will generally rise with the use of oem cnc parts and sophisticated machining

Roles of CNC Machining in Specific Renewable Energy Sectors

The market for green energy is now expanding. Green energy sources including wind, solar, and hydro are becoming more and more popular. Additionally, a majority of these components are the result of oem parts cnc machining technology. The greatest level of accuracy and extreme precision are required for the equipment and odm cnc milling parts utilized in renewable energy.

They are able to work harder and get the greatest results as a consequence.

Solar Power

The most well-known renewable energy source ever found may be solar electricity.

From the outside, the systems and gadgets appear to be rather simple, yet there are some significant advantages. For the solar panel to work effectively and absorb more electricity, it needs extremely accurate components. However, that is not the only factor. Apart from that, CNC machining is used to provide a high degree of precision while making the back and carrier rails, even the frames.

Drilling and milling machines work well for such jobs, and several businesses promote their CNC equipment as being especially useful for manufacturing solar panel components. Even big solar panel manufacturing lines include a variety of non-CNC procedures in addition to numerous operators operating at once. These non-CNC operations include cutting and drilling.

Additionally, plasma and fiber laser cutting equipment frequently specialize in the production of solar panels, with different lasers being employed for the actual panel-dividing process. Similar to this, other companies make solar panels using a combination of CNC machining and 3D printing. This does suggest that the development of hybrid products within the solar power sector may have room.

Wind Power

Wind energy generation needs robust, long-lasting components that can withstand extreme stress without losing precision. To handle wind pressure with the least amount of wear and tear, manufacturers must make precision blades. The fabrication of components like the enormous bearings that control the angle, as well as the production of the blades, has relied heavily on metal and carbon fiber machining.CNC allows for the production of large bearings with the same precision as smaller parts, such as those used in the adjustment mechanism of wind turbines. Similar to aviation engine blades, these large pieces must be extremely exact since mobility greatly affects how well they work.

In general, rotors, gearbox housings, and other components are turned on multipurpose lathe machines. Given the scale of the typical wind turbine, it necessitates the use of big, powerful machinery, with metal cutting accounting for around 90% of gear wheel production. These days, gear milling using a hob or disc cutters is predominant in this. Similar to how holes are frequently processed in tube shell heat exchangers for a range of energy systems, CNC drilling machines are employed in this procedure.

CNC machines that produce reinforced carbon-fiber plastics or glass fiber materials are necessary for wind turbines and windmills. The rotor blades can also be made of lightweight woods, aluminum, or fiberglass with a hollow core. Most rotor blade profiles resemble those of airplanes; hence these devices need extremely high levels of precision.

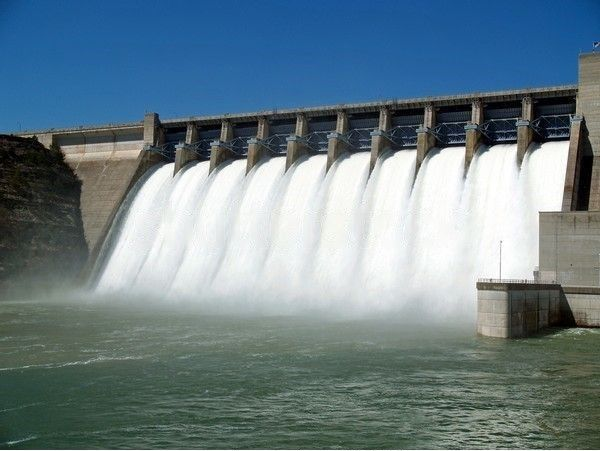

Hydro-Power

The turbines and generators used in hydropower are not only huge machinery. They must also be resistant to pressure and water damage and made of materials that share these features, frequently using carbon and stainless-steel components. CNC technologies are used by organizations of all sizes to make a variety of oem cnc parts, from straightforward shafts and bushings to housings, impellers, and coverings for hydro turbines.

Depending on the demands of the facility, it frequently entails turning, line boring, and milling on a large scale. For comparison, Canyon Hydro in North America makes use of a 7-axis CNC milling machine that can create Pelton and Francis hydroelectric turbines that are up to 16 feet in diameter and 25 tons in weight. Minor but possibly harmful flaws in the turbine are fixed using the CNC machine. This is one of several machines in their manufacturing facility. Even larger, the York plant of Voith Hydro fabricates workpieces up to 42′ (12.80 m) in diameter and 350 tons in weight (317.5 t).

In addition to turbines, the development of dam and hydropower plant gates uses CNC milling and other machining techniques. In certain instances, the development of various CNC machines has made it possible to produce these oem cnc machining parts locally rather of having them sent in from a distant manufacturer.

Why is CNC Machining Used for Green Energy?

The following are some of the reasons why CNC machining is a preferred method for producing components for renewable energy sources:

- finishing of a high caliber.

- widespread production

- Large portions could be present.

- On-site production is simple.

- really accurate and reliable.

Similar to many machine-made parts, the components needed for the energy industry must be of the highest quality and properly engineered to withstand strong forces, significant temperature fluctuations, and corrosion. The renewable energy industry employs CNC machining to the greatest extent feasible due to the speed and accuracy of the components that can be produced, and the green energy industry is greatly benefited by CNC machining and contemporary technology.

Sustainability Through CNC Machining

The current state of the global energy market illustrates the need to strengthen the resilience of economic development. In order to combat the pandemic, prevent a spike in carbon emissions, and stimulate the economy while laying the groundwork for a more secure and sustainable energy future, the EIA recommended that governments employ clean energy as the foundation of their economic relief plans. The capacity of CNC machines to consistently manufacture high-quality oem milling parts is required now more than ever.

Efficiency improvement is only one of the numerous advantages of CNC machines. It is being utilized by eco-aware businesses to significantly reduce their carbon impact. A Finnish study that discovered several ways that CNC machining reduces emissions was summarized in a publication by Science Direct. CNC machining minimizes transportation, which is one of the main ways it lowers emissions, but it also cuts down on wasteful material use and cutting time. By leaving machinery operating longer than necessary or disposing of a lot of garbage, less carbon dioxide is emitted into the atmosphere.

The creation of prototype components using CNC machines currently relies on Computer-Aided Design (CAD) files. These oem cnc parts are incredibly sophisticated and highly automated since every step of the operation is computer-controlled. Old industrial machinery like routers, drills, and lathes are operated by special computer programs, making CNC machining stand out, in order to reach such a fine degree of control. It is utilized extensively across a wide range of sectors since it streamlines the entire production process.

“In recent years, there have been several changes to CNC goods. Green living specialists need to be aware of the numerous developments occurring in the CNC sector.

Is CNC Machining Harmful to the Environment?

CNC machining is used in many highly industrialized countries to make oem machining parts for export and home usage. Although the GDP is increasing, the impact of carbon emissions from these operations remains a source of worry.

Business owners frequently assess success in terms of revenue. If a firm is always increasing, it is doing well. This seems sensible, yet it isn’t always the case.

In many circumstances, growing the firm at any cost is not the greatest option. This method poses considerable financial risks, not to mention the potential for environmental disaster.

It is feasible to reduce the environmental effect of CNC machining by employing lighter versions of machines instead of cast iron ones.

Conclusion

We are in a period when developing green energy components that are less harmful to the environment is essential. Conventional energy production methods can make use of safer, more environmentally friendly components. CNC machining results in parts for green energy that are more effective and of higher quality. When used properly and on updated equipment, CNC machining may considerably enhance corporate processes and provide green energy components for the creation of sustainable energy.