Introduction

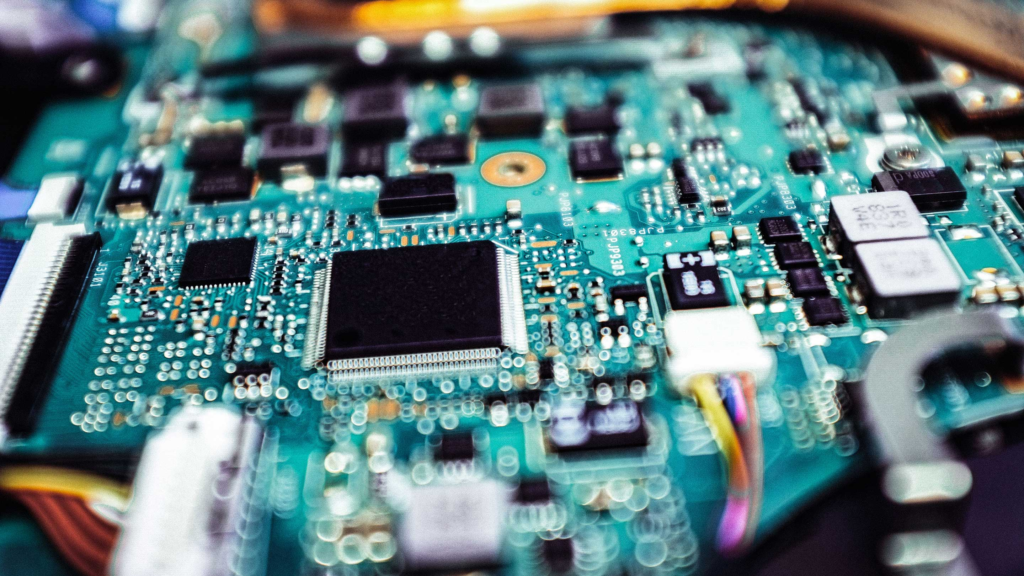

Due to the high demands of semiconductor parts, the semiconductor industry has become a rapidly growing industry. This increased demand is attributed to the use of semiconductor CNC machined parts in various integrated circuits and electronics. The semiconductor CNC machined components are custom designed to meet different electronics’ specific needs and play an important role in their function. Hence, the production of these semiconductor CNC machined parts requires high precision in terms of designs.

These semiconductors feature properties between conductors and insulators at room temperature. These features in combo with high precision make the manufacturing of semiconductor products critical. Based on our understanding and expertise, we offer support and high-quality manufacturing solution for various CNC semiconductor CNC machined parts. Let’s learn together now!

The Semi-Conductor Industry Today

Semiconductor parts are the brains of the modern-day era, while this industry is one of the major contributors to job creation in many advanced countries. The semiconductor market has become essentials and ubiquitous in everyday life. This is attributed to the high demand for more economical and powerful devices that depends on the semiconductor markets, such as cell phones, laptops, televisions, airplanes, military equipment, healthcare equipment, spacecraft, virtual and augmented reality devices, musical instruments, monitoring equipment, and many more. With this ever-increasing demand comes an increasing need for innovative solutions to address the challenges of semiconductor manufacturing. However, several factors are influencing the development of most semiconductor industries today. Read on to learn more!

Factors Influencing the Semi-Conductor Industry

The following are factors that influence the great demand and development of semiconductor industries around the world:

Digital Connectivity

Another factor influencing the development of the Semiconductor industry is digital connectivity. Due to the growth of sensor-driven smart word, it is predicted that most electronic devices will depend on IoT technology (Internet of Things) for communication. In years to come, this universal connectivity will govern virtually all devices and platforms ranging from infotainment to driverless technology, healthcare sensor communications, and many more.

Automation

To cater to the increasing demands of semiconductor parts, semiconductor industries require production processes that are highly efficient and automated. Production examples include a wide range of microchips systems on chips devices, fusion components, and many more.

Electrification

As opposed to oil and gas, there could be a dominant form of electric power resulting from regulations on reducing the carbon footprint on the planet and pollution control. This may give rise to the demand for semiconductor parts in a few years to come. Contemporarily, electrification is now seen in public transportation coupled with the growth of hybrid and electric vehicles.

Increased Level of Security

Another factor influencing the semiconductor is heightened security. As time goes on, there has been a great need to increase the level of security in every part of the world. Semiconductors are now being used to create security devices. They form an integral part on which most of these security devices function. To avoid interconnected devices and systems from malicious function or hacking, the device needs to feature an inbuilt security solution. In most cases, semiconductor serves as the bedrock for these security solutions.

Challenges of Semi-Conductor Manufacturing

Complexity in Manufacturing Semi-Conductor Designs

The wafer with a 150mm diameter can be very small, providing a house for a hundred semiconductor chips. These chips require the highest form of machining accuracy with the most perfect form of tight tolerances. However, a small hairline or dent fracture in such a device can make the semiconductor useless.

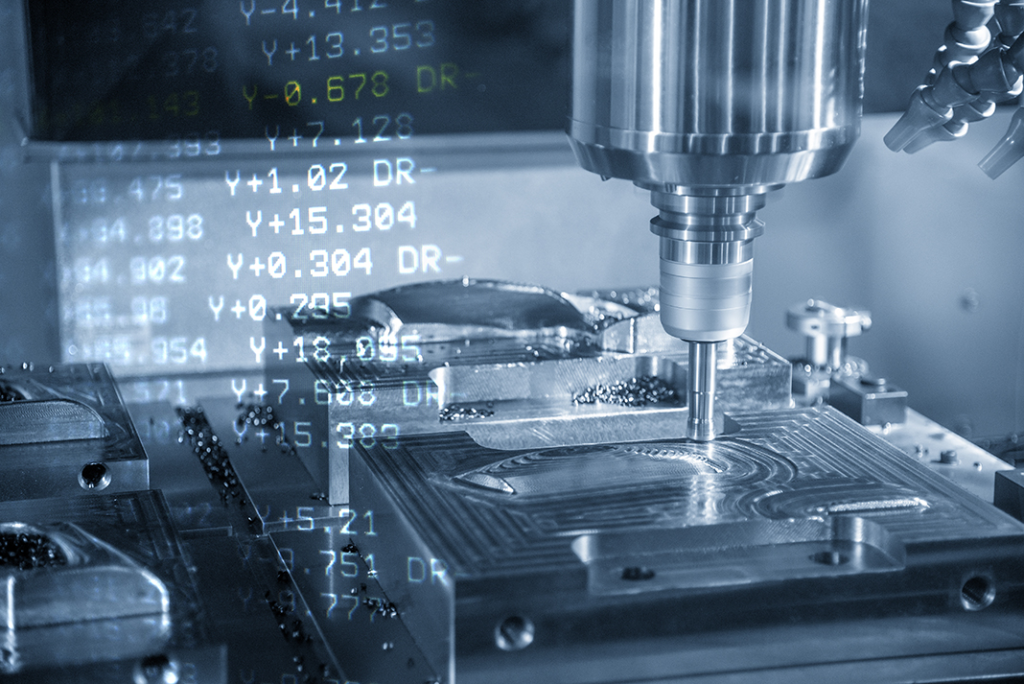

CNC machining plays a vital role in modern-day semiconductor machining. For instance, CNC milling machines allow users to ensure minimum tolerances on the surface of most semiconductor workpieces. CNC turning machines also allow you to achieve machine cylindrical semiconductor components. At the same time, you’ll meet the requirements for tolerance on cylindricity and circularity.

Challenges of Automation

As a result of the advancement in technology, semiconductors have spread from just cars and computers to pretty much any electronic products you can see around you. While this is impressive news for most semiconductor manufacturers, it’s the basic reason for the high demand for chips to continually outstrip supply recently. As a result, most semiconductor manufacturers have been tackling this dynamic demand phenomenon to meet the high volume needs via automation. With automation, manufacturers can use CNC machining to automate production to manufacture a large quality of custom parts or pre-machined pieces. The goal is to achieve a fast turnaround and delivery time to meet up the needs of their customers.

Slow Turnover System

Given the length of time required to manufacture semiconductor parts, downtime translates into a material and financial cost in the manufacturing process. As a result, traditional machining processes take time, while CNC machining makes it faster to manufacture these semiconductor parts. As a result of the increasing demands for increased turnover rate and delivery, there is an increase in the use of CNC technology to automate manufacturing for semiconductor parts.

Challenges of Semi-Conductor Materials

In the semiconductor industry availability of varieties of material options is a major factor that influences development. However, despite the varieties of materials available for use, selecting the perfect and the right choice is a great challenge. This challenge can be eliminated only by great professionalism and expertise in the semiconductor industry. This means that factors such as durability, machinist technical know-how, the environment of use, and many other important factors must be considered when using the perfect materials for a project.

Choosing Quality Machining Solution for all Semi-Conductor Production

A wide variety of semiconductor components are small but complex in design. In contrast, others are rather big with complex and less complex designs. Irrespective of these, CNC machining technology allows intricate part production and micro dimensioning. To meet the needs in demands in this industry, manufacturers of semiconductor components must invest in the right CNC machine tools. Quality machining solution provides better performance, but it also ensures a decrease in cost per part manufacturing in both the short and long term. This is especially crucial for intricate, complex, and costly large part semiconductor parts. Also, choosing a quality machining solution for your semiconductor manufacturing ensures the following advantages:

- Improved surface quality

- Greater consistent accuracy

- Faster production cycle

- Improved flexibility

- Longer-lasting cutting tools

- Greater machine rigidity

- Quality parts produced via linear guideways for better rigidity, long life span, and quicker cycle times)

- Improved spindle design and reliability

- Stable machine performances

- Steady accuracy and precision

Factors & General Rules to Consider in Choosing Quality Machining Solution

From the defense department to aerospace, electronic business and organizations need precision manufacturing to complete their projects. Without precision, manufacturing processes and operations will come to a stop. Yet, depending on just any machining solution to provide any needed parts can lead to a new form of problems. This is why you need to understand the following guidelines in choosing a quality machining solution:

Large Milling Capacity

To access a quality semiconductor machining solution, a manufacturer must offer state-of-the-art milling machines. These machines must easily cut through solid materials such as aluminum, copper alloys, stainless steel, titanium, steel alloys, plastic, and many more. Also, such manufacturers must be automated to carry out extensive CNC machining processes. And they must effectively create solid models in large quantities without sacrificing quality.

A high-quality semiconductor machining solution must offer state-of-the-art equipment to achieve swift production. Such service must lie in the use of the latest technology for mass production. As a result, you’ll have access to manufacturing satisfaction regarding all your projects.

Execution of all Production Phases

For effective and efficient product manufacturing, you must ensure to employ manufacturers that will execute all phases of production in manufacturing your semiconductor components. A good CNC machining product qualification rate should be above 96%. Hence, rely on manufacturers whose pride is in the high-quality production and satisfaction of clients.

Affordability in terms of Price

Another factor to consider is the affordability of services compared to other CNC machining industries. They must provide impressive services that will control cost consumption of raw materials, shipment, transportation, and more with affordability.

Swift Shipment of Manufactured Parts

A state-of-the-art semiconductor machining solution must offer professionalism in this space regarding time compression. As a result, this will help simplify a complete production process efficiently and effectively in a short time. You will maximize manufacturing capabilities according to the production cycle during this short time. A fast shipment cycle is important for every business. It must take a little time as soon as production is completed.

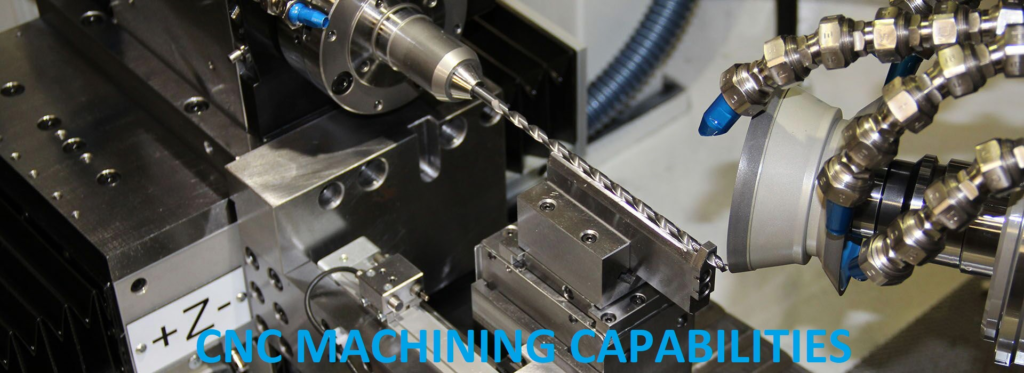

Our CNC Sem-Conductor Cavity Machining Capabilities

We offer different types of semiconductor parts made from high-strength materials with our expertise. Due to our professionalism and many years of expertise, we produce various kinds of semiconductors using the following tools:

We offer a complete set of CNC machining tools that ensure impressive function with the required capacity to produce a wide variety of parts.

3-Axis CNC Milling Machine

Our 3-Axis CNC Milling Machine is well-known for the rudimentary technological option it offers in terms of modernization. This CNC milling tool is most widely used in manufacturing mechanical parts in industrial work, manufacturing, architecture, and many more. Its features 3-axis including X, Y, Z shaving down the material into your designed shape.

4-Axis CNC Milling Machine

We also offer the 4-Axis CNC Milling Machine that introduces the fourth axis that helps ensure rotation around the vertical axis. This tool functions in machining involving advanced carving and millwork.

5-Axis CNC Milling Machine

Our 5-Axis CNC Milling Machine features 5-axis movement, including (A, B, X, Y, and Z). This allows for parts manipulations in all directions during one operation. This machine is ideal for deeper parts, more precision, high-quality manufacturing, and more. Due to flexibility, it’s advantageous for on-time manufacturing compared to the 3-axis and 4-axis CNC Milling Machine.

CNC Turning Machine

We also offer a CNC machine, mostly called lathe, which can either be vertical or horizontal depending on the weight and tolerance of your semiconductor workpiece. Our CNC turning machine offers a turning center that effectively rotates your workpiece to achieve your designs. Another exciting part of this machine is a tool that helps enhance high-quality manufacturing by moving to and fro into the workpiece to cut your workpiece into the desired shape.

Gantry Milling Machine

Another state-of-the-art machine we offer is the Gantry Milling Machine. This milling machine features a long horizontal bed and a gantry frame. The capability of our gantry milling machine is the machine surface of the workpiece simultaneously using multiple milling cutters. You can be assured that processing accuracy and production efficiency are on the high side. Work envelops up to 6500mm X 4200mm X 1800mm, and it’s suitable for flat and beveled surfaces in large-sized workpieces both in batch and mass production.

Aside from these stat-of-the-art machines, we also offer testing equipment to help ensure high-quality production. This equipment includes:

- CMM

- Two-dimensional microscope

- Two-dimensional projector

- Spectrometer

- Height gauge testing equipment and many more.

CNC Semiconductor Materials We Offer

We offer various semiconductor materials for semiconductor component manufacturing. They include and are not limited to the following:

Metals

Aluminum

Aluminum exists as one of the commonly used CNC metals in the world of CNC today due to its excellent low cost, strength-to-weight ratio, and recyclability. Aluminum exists in varieties of alloys that can be used to achieve many finishes. We offer various alloys of aluminum which are not limited to:

- 7075 – aluminum

- 7050 – aluminum

- 6063 – aluminum

- 5052 – aluminum

Plastics

Aside from metals, we also offer varieties of plastic materials. Plastic materials are semiconductors and are applicable in CNC machining. Some of the types of plastic materials we offer include:

- PVC

- Nylon

- PEEK

Application of CNC Semi-Conductor Machining

Large CNC machining for semiconductor part manufacturing is important in varieties of applications/use. This CNC machining for semiconductor part manufacturing is a sub-division of the esteemed CNC machining. It offers a wide variety of advantages, such as precision and accuracy. We offer small- and large-scale CNC machining for semiconductor parts or components in the following sectors;

- Power & Energy Generation

- Oil & Gas industries

- Mining industries

- Hydro-Electric

- General Construction

- Printing Industries

- Food Processing industries

- Custom Machinery

- Communication

- Aviation

- Automotive industries

- Architectural Industries

- Utilities

Why Work with Us for Your Semiconductor Manufacturing

As a sophisticated CNC Sem-Conductor Cavity Machining manufacturer, we provide custom CNC machining services for all semiconductor components. We are capable of delivering accurate, and precision machined semiconductor parts. Our experts, designers, and operators have what it takes to accomplish any task from the start of the project to the design, production, and end product with offers of the most cost-effective solutions. Also, with a wide variety of machining services, including CNC milling, turning, surface treatment, and drilling, we offer the best capability to manufacture semiconductors of different sizes, tolerances, applications, requirements, and materials. Hence, working with us on your semiconductor manufacturing comes with the following advantages:

- Fast turnaround time

- On-time finished product delivery

- Great flexibility in manufacturing volumes

- Affordability of semiconductor parts

- High process yields and excellent particle performances

- High-end quality of semiconductor parts that conforms to industrial standards

CNC Semi-Conductor Machining FAQs

- Do you require CNC machining for Semiconductor prototypes?

Yes, we require prototypes for your projects. We can start production as soon as you provide a prototype. However, our professionals can provide you with impressive prototypes based on your project requirements if you don’t.

- What order volume do you accept?

Irrespective of the size of your order, either small or large, we’ve got you covered. Contact us through any of our contact details, or submit your info via our contact form.

- Do you offer machining solutions for complex parts?

Yes, for semiconductor component machining, we offer high-quality precision machining and manufacturing services irrespective of the project’s complexity.

- Do you inspect all the parts before shipping?

Yes, we normally inspect our products before we ship all parts. This is to ensure that the shipment is free from error or defects. Our quality control team will inspect all shipments to achieve our client’s goal.

- Do you offer test reports?

Yes, based on our expertise, we have varieties of testing equipment. As a result, we will provide you with the test reports for proper review if requested. This will fill you in on the status of our progress concerning your project requirements.

Conclusion

Designing and manufacturing are our areas of expertise. Our expert team prides itself in providing CNC semiconductor manufacturing solutions for simple and complex parts in the semiconductor manufacturing space. Put us to test today – then, you’ll know that your happiness is our happiness. We offer the capability to take on new projects in semiconductor machining solutions using our state-of-the-art equipment.