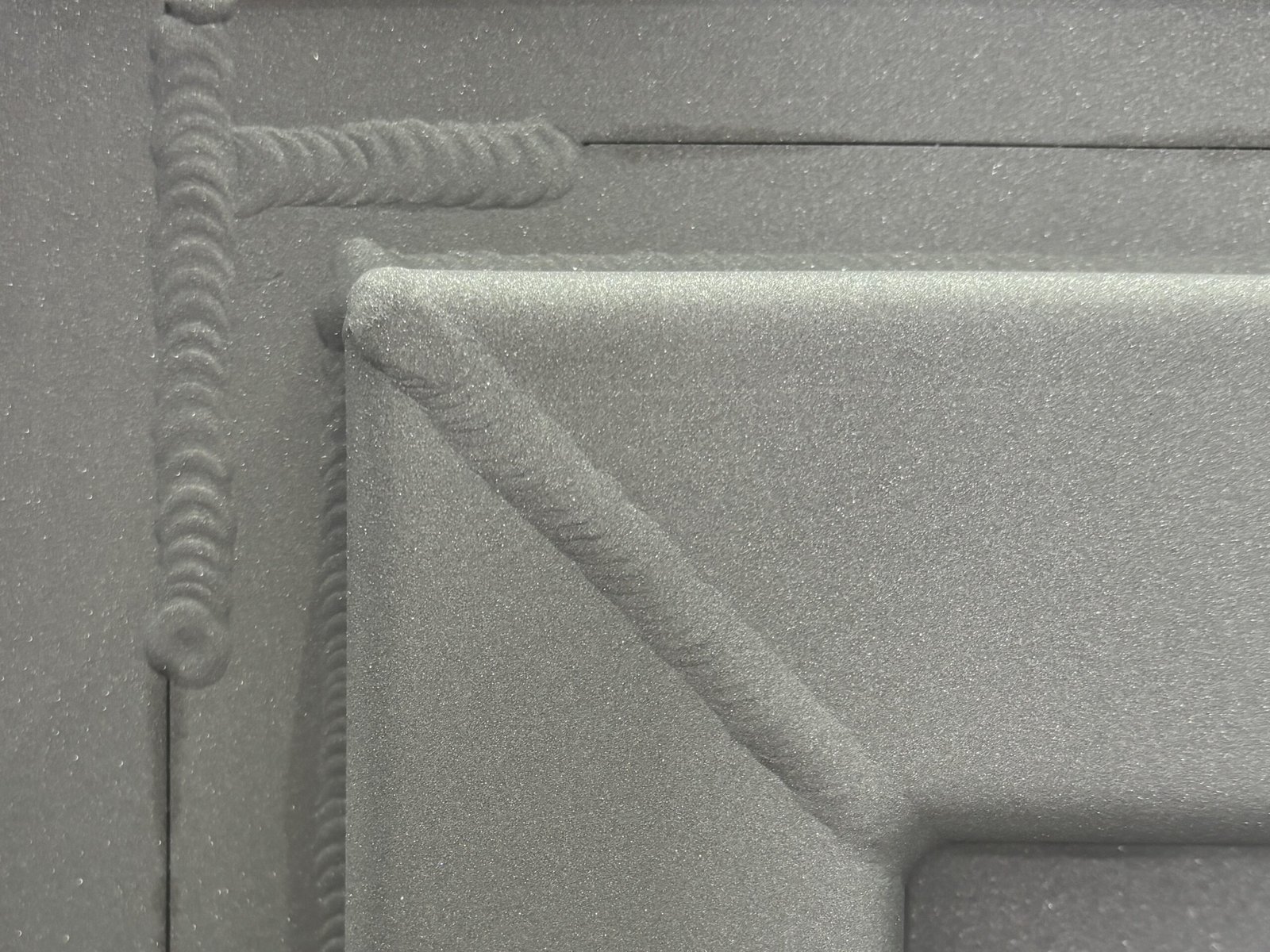

Bead blasting is a precision surface treatment process that projects uniform-sized media (such as glass beads, aluminum oxide, or ceramic beads) at high pressure onto workpiece surfaces, creating uniform micro-indentations to achieve specific surface effects. This technology is widely applied to surface treatments of various metallic and non-metallic materials, effectively enhancing product performance and aesthetics.

Glass Beads

Carborundum

Core Benefits of Bead Blasting:

20+ Years of Precision Expertise: More than 20 years of custom machining excellence.

Global Quality Standards: International quality protocols meet the exacting requirements of European, American, and Asian markets.

Complete Manufacturing Solution: Full industrial chain across automotive, marine, medical, and semiconductor, etc.

Comprehensive Bead Blasting Technology Solutions: With 20 years of precision machining experience, we provide comprehensive industrial blasting solutions that are not just a surface treatment process, but a key procedure to enhance product performance and value. Our blasting services combine advanced equipment, professional technology, and strict quality control to create high-quality surface treatment effects that meet exact specifications for clients across various industries.

Industrial blasting, as an important surface treatment process, can be classified from multiple dimensions, mainly including blasting media (material), blasting method, and application purpose. Our display of blasting methods classified by material comprehensively covers various blasting media from metallic, mineral/ceramic to organic types, providing customers with the best selection basis. In the field of precision CNC manufacturing, commonly used blasting materials mainly include: Glass Beads, Ceramic Beads, Aluminum Oxide, and Plastic Media.

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Our blasting process uses a computer control system to precisely regulate key parameters, ensuring optimal results:

We implement a strict three-stage quality control process to ensure each blasting project meets client expectations:

1. Pre-process Quality Check:

2. In-process Quality Monitoring:

3. Finished Product Quality Verification:

We can precisely control the surface roughness after blasting, meeting the most stringent industry requirements:

| Roughness Level | Ra Value Range(μm) | Typical Applications | Recommended Blasting Media |

| Ultra-fine | 0.1-0.3 | Optical elements, reflectors | Glass beads #180 – #220 |

| Fine | 0.3-0.8 | Semiconductor parts,precision electronics | Glass beads #100 – #150 |

| Standard | 0.8-1.5 | Medical devices,precision machinery | Glass beads/Ceramic beads #80 – #100 |

| Medium | 1.5-3.0 | Automotive parts,general machinery | Aluminum oxide/Ceramic grit #60 – #80 |

| Coarse | 3.0-5.0 | Heavy industry,marine components | Steel shot/Aluminum oxide #40 – #60 |

We use state-of-the-art measurement technologies to ensure surface quality:

Professional blasting services for semiconductor vacuum chambers and critical components:

1. Special Requirements: Extremely low particle residue, no metal contamination

2. Recommended Process: Glass bead blasting (#80-#120), Ra value controlled at 0.3-0.8μm

3. Dedicated Equipment: High-purity closed system preventing cross-contamination

Quality Standards: Compliant with SEMI standards, 100% full inspection

Durable surface treatment for large marine and industrial parts:

1. Special Requirements: Extreme corrosion resistance, high-adhesion substrate preparation

2. Recommended Process: Steel shot blasting (#40-#60), Ra value controlled at 2.0-4.0μm

3. Dedicated Equipment: Large blasting chamber capable of processing workpieces up to 3000×1500×1000mm

4. Quality Standards: Compliant with SSPC-SP and ISO 8501 standards

Share your project requirements with us and let our expert team provide high-precision solutions for your challenges. 20 years of exceptional craftsmanship, dedicated to your next successful project. Contact us today to start our partnership journey.

Bead blasting is a precision surface treatment process that projects uniform-sized media (such as glass beads, aluminum oxide, or ceramic beads) at high pressure onto workpiece surfaces, creating uniform micro-indentations to achieve specific surface effects. This technology is widely applied to surface treatments of various metallic and non-metallic materials, effectively enhancing product performance and aesthetics.

Glass Beads

Carborundum

Core Benefits of Bead Blasting:

Comprehensive Bead Blasting Technology Solutions: With 20 years of precision machining experience, we provide comprehensive industrial blasting solutions that are not just a surface treatment process, but a key procedure to enhance product performance and value. Our blasting services combine advanced equipment, professional technology, and strict quality control to create high-quality surface treatment effects that meet exact specifications for clients across various industries.

Industrial blasting, as an important surface treatment process, can be classified from multiple dimensions, mainly including blasting media (material), blasting method, and application purpose. Our display of blasting methods classified by material comprehensively covers various blasting media from metallic, mineral/ceramic to organic types, providing customers with the best selection basis. In the field of precision CNC manufacturing, commonly used blasting materials mainly include: Glass Beads, Ceramic Beads, Aluminum Oxide, and Plastic Media.

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Characteristics & Advantages:

Typical Applications:

Our blasting process uses a computer control system to precisely regulate key parameters, ensuring optimal results:

We implement a strict three-stage quality control process to ensure each blasting project meets client expectations:

1. Pre-process Quality Check:

2. In-process Quality Monitoring:

3. Finished Product Quality Verification:

We can precisely control the surface roughness after blasting, meeting the most stringent industry requirements:

| Roughness Level | Ra Value Range(μm) | Typical Applications | Recommended Blasting Media |

| Ultra-fine | 0.1-0.3 | Optical elements, reflectors | Glass beads #180 – #220 |

| Fine | 0.3-0.8 | Semiconductor parts,precision electronics | Glass beads #100 – #150 |

| Standard | 0.8-1.5 | Medical devices,precision machinery | Glass beads/Ceramic beads #80 – #100 |

| Medium | 1.5-3.0 | Automotive parts,general machinery | Aluminum oxide/Ceramic grit #60 – #80 |

| Coarse | 3.0-5.0 | Heavy industry,marine components | Steel shot/Aluminum oxide #40 – #60 |

We use state-of-the-art measurement technologies to ensure surface quality:

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.