A great digital prototype can go from idea to reality. Creating a successful manufacturing strategy, market research, testing products, and using intelligent strategy will help your product go from prototype to production and be a success. Prototyping is a crucial step in the product development process, as it helps you to validate your idea before investing in it. It also helps you to better understand the potential problems that might arise during production.

Prototyping allows you to create a model of your idea that can be tested for its viability and usefulness. It also allows for changes to be made before moving on to production, which saves time and money. Turning a design into reality is phenomenal, as most designs die before becoming a reality. To avoid failures and wasting a lot of money and time, one should concentrate on a few key points such as market research, product material, manufacturing capability, customer reviews, and product cost.

This article covers all the KPIs, strategies, and techniques that help you in achieving a successful product from the prototype.

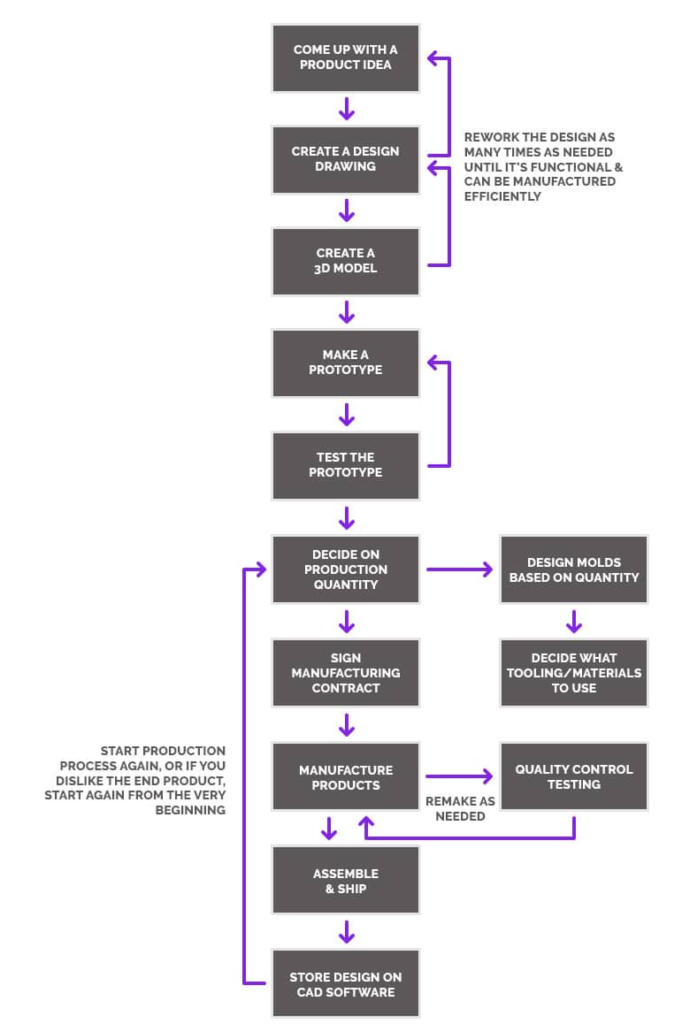

Prototyping to Production: A complete Pathway

Moving from the prototype to production is often a very satisfying achievement, especially for newbies. It is a widely held misconception that if a manufacturing process works for one product, it will also work for others. Every product, however, requires its own market research, design concepts, working principles, prototyping, and manufacturing techniques. As a result, before beginning the procedure, one should conduct extensive research.

A general manufacturing technique is as follows.

The manufacturing process always starts with a unique concept design. Experienced professionals help you in converting your concept design into a 3-D model with the help of sketching and rendering software. In engineering, they are mostly Solid works, PTC cero AutoCAD and fusion. The 3-D modeled design is then subjected to some Engineering analysis to check its working, strength, durability, and Stress bearing properties. A manufacturer can gain an understanding of how his product will perform under specific conditions.

If the analysis is favorable and supports the implementation of the product, then it's time to go for a mock-up model. A mock-up model provides a real-time representation of the product, allowing you to understand the manufacturing and technical flaws if any exist. Companies frequently use these mock-up models to collect data on customer needs, improvements, and any necessary changes. These mock-up models are very useful when dealing with electrical and mechanical parts because the manufacturing of these parts requires tight tolerance and precision. By implementing this procedure, you have a lot of room for improvement and changes.

The final and most important step is to select the right manufacturer. If you are pleased with the prototype and have high confidence in the product, it is time to select the right manufacturer to begin the production process. You should always check whether your manufacturer has the necessary machinery and skills to provide you with a slashing product. Before finalizing, you must sign a manufacturing agreement and check the international standards. Although this process may appear to be straightforward and simple, meeting international standards and creating high-quality products is a challenging task that requires a lot of back and forth.

Prototyping and design:

As we all know, there is a complete process from prototype to production. However, each process has some additional technicalities to achieve manufacturing excellence.

Conceptual prototype:

A conceptual prototype is a prototype that needs to be more detailed but still communicates the idea of the product. It is a low-fidelity representation of the final product. Making a 3 -D product model and performing a working analysis on it, can figure out the need for improvements at a very early stage.

This type of prototype can be used to test whether or not your idea has potential in the market without spending too much time and money on it. It can also help you to figure out how people will interact with your product before you start investing in it.

Feature Prototyping:

The second step in the prototyping technique is feature prototyping, which involves creating a mock product model based on the approved design from experienced professionals. The mock-up model depicts each and every technicality of the final product. You can thoroughly understand all flaws and manufacturing requirements for materials, surface finishing, mating part precision, and tolerance. In addition, the manufacturer can determine which manufacturing technique is best for lean manufacturing and bulk production. A low-volume production is an option if you're dealing with common parts with simple geometry and no complex components; however, if complex geometries are involved, evolutionary prototyping is the wiser choice.

Evolutionary Prototyping:

Complex mechanical and electrical parts that require high precision, surface finishing, and real-time product testing require an evolutionary prototyping technique. Parts manufactured for the aerospace and automobile industries have complex geometries and require excellent results in durability, material strength, surface finishing, and aesthetic appearance with tight tolerance. As a result, low-volume prototype production is always recommended for them. Once the company is ready and the prototypes have been approved, the production process can begin. If there are any changes that need to be made, an improved prototype is created again before production.

Creating a Successful Manufacturing Strategy

Now that you have a complete and approved prototype, you are ready to begin the manufacturing process, and here are the manufacturing KPIs for a smooth and lean manufacturing process.

Do a Good Market Research:

The success of your product depends on several factors, including thorough market research, an understanding of customer needs, the manufacturing purpose, the material to be used, and the price range appropriate for the intended market. The manufacturer should be open to suggestions for improvement and useful condemnation.

Most manufacturers and businesses conduct activities such as customer reviews, survey feedback, and real-time product usage to optimize the product based on market feedback. Finding the best product gap also involves researching and keeping an eye on the competition.

Understand the Properties of the Material:

The most important process before beginning manufacturing is selecting the appropriate material. The material should be chosen based on durability, strength, toughness, temperature resistance, and required aesthetics. Before making any decisions, keep the following points in mind.

- The material should be Easily available.

- It should be cheap, otherwise, your product cost may increase.

- It should give a good weight-to-strength ratio, durability, resistance to temperature, and stresses.

- It should be ideal for machining otherwise it may increase your product cost.

- It should be compatible with your chosen manufacturing process.

- It should be favorable for bulk production and lean manufacturing.

- The material should be compatible with the post-processing procedures and gives a good surface finish.

These are the general key points, but they are not applicable when you are dealing with highly complex or specific parts, like aerospace and automobiles where budget is not an issue, the extremely high quality and strength are the only targets.

Low production Volume:

Always start with a low production volume or a pilot run, as the product may need some improvement after some applications, and by starting from a small batch you can save a lot of money. When the product is all good to go, then bulk production and using modern manufacturing equipment and tools are the best option, as they can save a lot of money and time with respect to an ordinary one.

Documentation:

Choosing the right manufacturing unit and doing proper Contract documentation, saves you from a great headache in the future. A well-written document covering all points regarding, prototype, production, material, quality, and guarantee should be signed. Furthermore, you must check the company’s history, its completed project, and its expertise before signing it.

Keep a close eye on the budget:

Unplanned manufacturing may cause you a lot of monetary damage, so it is always advised to keep a close eye on it. Do not spend too much money on making prototypes, Surveys, and ideas.

Choose the right Manufacturing:

Doing complete research and discussing it with the experts can save you a lot of bucks for you. Before choosing a machine shop for your manufacturing project, you should make sure that they have desired machinery and expertise in the field. For example, if you desire 3-D printing technology, then make sure they have that kind of machinery, certifications, and expertise or not.

At Baichuan we have a wide range of modern machinery and tools, your product is in the hands of expert engineers and machinists from the start to the end. You can consult with our team at any time to discuss, your project, Design, prototype, material, or anything related to manufacturing in which you are doubtful. At Baichuan you can have each thing from designing, prototyping, production, and improvement under one roof.