Struggling with premature tool failure? Poor surface finishes? Excessive downtime? Selecting the wrong tool steel can devastate precision machining operations and drive costs through the roof.

Tool steel selection hinges on matching material properties to application demands. The optimal choice balances hardness, wear resistance, toughness, and heat resistance while considering workpiece material, cutting parameters, and production requirements. Proper selection extends tool life and enhances machining quality.

Tool steel selection process

As a custom CNC machining facility, I've seen firsthand how tool steel selection can make or break a project. The difference between success and failure often comes down to understanding the complex relationship between material properties and application requirements. Let's explore the critical factors that drive these decisions.

What factors determine tool steel selection for precision CNC machining?

Selecting inappropriate tool steel is like trying to cut hardwood with scissors - frustrating, inefficient, and potentially damaging to your equipment and reputation.

Tool steel selection depends primarily on workpiece material hardness, cutting speed requirements, temperature resistance needs, and tool geometry. Harder workpieces demand tougher tool steels with superior wear resistance, while complex geometries may require steels that maintain edge integrity under stress.

Tool steel varieties for CNC machining

Tool steel selection involves balancing multiple competing factors to achieve optimal performance. The AISI classification system provides a structured approach, categorizing tool steels into groups like water-hardening (W-series), shock-resistant (S-series), cold-work (A, D, and O series), hot-work (H-series), high-speed (M and T series), and special purpose varieties.

When machining abrasive materials like cast iron or hardened steels, we typically select high-speed steels or carbides with excellent wear resistance. For heavy-duty applications where tools experience significant impact forces, shock-resistant steels containing silicon, manganese, and molybdenum prove invaluable. The chemical composition directly influences performance - carbon content affects hardness potential, chromium improves wear resistance, vanadium enhances edge retention, and molybdenum increases hot hardness.

In our factory, we maintain detailed records of tool performance across different applications. This data-driven approach allows us to refine our selection process continuously, matching specific tool steels to particular customer requirements for maximum efficiency and cost-effectiveness.

How does heat treatment affect tool steel performance in manufacturing?

Pain point: Improper heat treatment can render even premium tool steels useless, causing catastrophic failures during critical machining operations and resulting in costly project delays.

Heat treatment transforms tool steels by altering their microstructure, enhancing hardness, wear resistance, and strength. The process includes precise heating, quenching, and tempering cycles tailored to each steel type. Proper treatment balances hardness and toughness while minimizing distortion and stress.

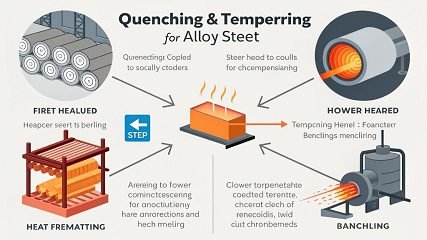

Tool steel heat treatment process

Heat treatment represents perhaps the most crucial step in developing optimal tool steel properties. The process begins with austenitizing—heating the steel to a specific temperature where its crystalline structure transforms, allowing carbon and alloy elements to dissolve into solid solution. This temperature varies significantly between steel types; for instance, water-hardening W1 tool steel might austenitize at 790°C, while high-speed M2 requires temperatures exceeding 1200°C.

Quenching methods also vary dramatically based on steel composition. Oil quenching provides moderate cooling rates suitable for many alloy tool steels, while air cooling works for highly alloyed steels like D2 or A2. Water quenching, though faster, introduces higher distortion risk and is generally reserved for simple geometries in plain carbon tool steels.

Tempering follows quenching and involves reheating the hardened steel to reduce brittleness and internal stress. Many tool steels require multiple tempering cycles to achieve dimensional stability and optimal property combinations. The temperature-property relationship is non-linear; for example, secondary hardening steels like H13 actually increase in hardness when tempered at specific temperature ranges due to fine carbide precipitation.

In our machining operations, we've developed specialized heat treatment protocols for different tool applications. Tools used for high-temperature cutting operations receive different tempering cycles than those designed for impact resistance, ensuring each performs optimally in its intended application.

How do different tool steel classifications impact machining accuracy?

The wrong tool steel classification can lead to dimensional inconsistencies, poor surface finishes, and frequent rework—costing thousands in wasted materials and labor while damaging customer relationships.

Tool steel classifications directly impact machining precision through their unique combinations of wear resistance, dimensional stability, and edge retention. High-speed steels excel in general machining, while cold-work tool steels provide superior dimensional stability. Advanced powder metallurgy grades offer exceptional consistency for the most demanding precision applications.

Machining accuracy with different tool steels

The correlation between tool steel classification and machining accuracy manifests in several critical ways. A-series cold-work steels like A2 and A6 offer excellent dimensional stability during heat treatment, making them ideal for precision gauging applications and complex forming dies. Their moderate carbide content provides good wear resistance without sacrificing grindability or machinability.

D-series steels, with their high carbon and chromium content, deliver superior wear resistance and edge retention. These properties make them particularly valuable for machining abrasive materials where tool wear can quickly compromise dimensional accuracy. However, their larger carbide structures can sometimes limit achievable surface finishes compared to finer-grained alternatives.

High-speed steels (M and T series) maintain their hardness at elevated temperatures, allowing for higher cutting speeds without dimensional drift due to thermal softening. This property is especially valuable in high-production environments where tool temperature fluctuations could otherwise compromise consistency.

Powder metallurgy has revolutionized tool steel performance by creating materials with extremely uniform microstructures and finely distributed carbides. These advanced grades exhibit superior grindability and dimensional stability during heat treatment, enabling the production of complex tool geometries with extremely tight tolerances. In our precision machining operations, we've found that PM-based tool steels can maintain dimensional accuracy up to 30% longer than their conventional counterparts under identical cutting conditions.

What are the tradeoffs between hardness and toughness in manufacturing applications?

Manufacturing engineers often face a frustrating dilemma: choose harder tool steels that wear prematurely due to chipping, or tougher options that deform gradually but predictably—both scenarios increase costs and downtime.

The hardness-toughness tradeoff represents a fundamental challenge in tool steel selection. Harder steels (65+ HRC) offer superior wear resistance and edge retention but are prone to chipping under impact. Tougher steels better absorb shock and resist fracture, but may wear faster. The optimal balance depends on application-specific stress patterns.

Hardness vs toughness tradeoff

The inverse relationship between hardness and toughness creates complex decision matrices for manufacturing applications. Hardness, measured in HRC (Rockwell C scale), correlates strongly with wear resistance and compressive strength. However, as hardness increases, ductility and impact resistance typically decrease. This tradeoff becomes particularly critical in interrupted cutting operations where tools experience cyclical loading.

Modern metallurgical advances have somewhat expanded the possibility frontier. For example, matrix high-speed steels like ASP 2023 and CPM REX 76 achieve hardness values exceeding 70 HRC while maintaining reasonable toughness through their unique microstructural characteristics. These advanced materials feature fine, uniformly distributed carbides in a tough matrix, mitigating the traditional tradeoff.

Application-specific considerations further complicate selection decisions. In high-speed machining of hardened steels, edge retention may be the limiting factor, favoring harder tool materials despite potential brittleness. Conversely, in heavy roughing operations with variable cutting loads, toughness becomes paramount to prevent catastrophic tool failure.

Through careful analysis of failure modes in our machining operations, we've developed application-specific guidelines. For custom vacuum chamber components requiring tight tolerances and excellent surface finish, we typically select CPM S90V at 58-60 HRC, providing an optimal balance for this application. For heavy-duty automotive components experiencing variable cutting forces, we prefer steels like S7 at 54-56 HRC, sacrificing some wear resistance for enhanced impact toughness.

Conclusion

Selecting the optimal tool steel requires balancing material properties against application demands. By understanding classification systems, heat treatment effects, and property tradeoffs, we deliver superior custom machined parts that meet precise specifications while maximizing production efficiency.