Bead Blasting

- Multiple Blasting Media Options

- Precise Process Control

- Customized Solutions

- One-stop Processing Service

what is Bead Blasting?

Bead blasting is a precision surface treatment process that projects uniform-sized media (such as glass beads, aluminum oxide, or ceramic beads) at high pressure onto workpiece surfaces, creating uniform micro-indentations to achieve specific surface effects. This technology is widely applied to surface treatments of various metallic and non-metallic materials, effectively enhancing product performance and aesthetics.

Glass Beads

Carborundum

Core Benefits of Bead Blasting:

- Enhance surface corrosion resistance

- Improve product aesthetic appeal

- Extend product service life

- Enhance component functionality

- Improve surface electrical conductivity

- Optimize light reflection and absorption

- Enhance thermal property management

Why Choose Us?

20+ Years of Precision Expertise: More than 20 years of custom machining excellence.

Global Quality Standards: International quality protocols meet the exacting requirements of European, American, and Asian markets.

Complete Manufacturing Solution: Full industrial chain across automotive, marine, medical, and semiconductor, etc.

Fast quote

Fast delivery

Fast delivery

Strong supply chain

File Security

1 to 1 service

Why Choose Us ?

Comprehensive Bead Blasting Technology Solutions: With 20 years of precision machining experience, we provide comprehensive industrial blasting solutions that are not just a surface treatment process, but a key procedure to enhance product performance and value. Our blasting services combine advanced equipment, professional technology, and strict quality control to create high-quality surface treatment effects that meet exact specifications for clients across various industries.

Classification by Blasting Media (Material)

Industrial blasting, as an important surface treatment process, can be classified from multiple dimensions, mainly including blasting media (material), blasting method, and application purpose. Our display of blasting methods classified by material comprehensively covers various blasting media from metallic, mineral/ceramic to organic types, providing customers with the best selection basis. In the field of precision CNC manufacturing, commonly used blasting materials mainly include: Glass Beads, Ceramic Beads, Aluminum Oxide, and Plastic Media.

Characteristics & Advantages:

- Made from premium Sodalime glass, spherical particles ensure uniform effect

- Does not alter workpiece dimensions, provides delicate matte surface

- Suitable for decorative surface treatment and light cleaning applications

- Grit size range: #20-#200, adapting to various precision requirements

Typical Applications:

- Medical device surface treatment

- Stainless steel decorative part matte finishing

- Electronic component and optical part cleaning

- High-precision mold surface optimization

Characteristics & Advantages:

- Made from high-purity aluminum oxide, high hardness with strong cutting ability

- Rapidly removes surface oxides, coatings, and contaminants

- Creates higher surface roughness, enhancing coating adhesion

- Grit size range: #16-#240, offering diversified surface effects

Typical Applications:

- Steel structure rust removal and surface preparation

- Roughness treatment before coating

- Casting surface cleaning and modification

- Aerospace component surface treatment

Characteristics & Advantages:

- Electrofused from zirconium oxide and silicon dioxide, hardness between glass beads and aluminum oxide

- Provides superior surface uniformity and predictability

- Long service life, low fracture rate, high cost-effectiveness

- Usable in both dry and wet systems

Typical Applications:

- Special stainless steel surface treatment

- High-end precision part processing

- Products requiring uniform matte effect

- High-requirement aerospace and medical components

Characteristics & Advantages:

- Made from hardened steel, provides the strongest impact force

- Ideal media for surface strengthening and stress relief

- Can quickly remove heavy oxidation layers and rust

- High durability, can be recycled multiple times

Typical Applications:

- Large steel structure surface treatment

- Cast iron part cleaning and strengthening

- Surface stress relief and strengthening

- Heavy coating and rust removal

Characteristics & Advantages:

- Gentle and non-damaging surface treatment method

- Does not cause surface thermal damage or metal contamination

- Suitable for soft materials and precision components

- Offers various hardness grades to adapt to different applications

Typical Applications:

- Aircraft skin and composite material treatment

- Electronic component and PCB cleaning

- Automotive part refurbishment

- Precision plastic part deburring

Characteristics & Advantages:

- Extremely high hardness and cutting ability, second only to diamond

- Efficiently removes stubborn dirt and hard coatings

- Creates rougher surface texture

- Suitable for rapid processing of hard materials

Typical Applications:

- Hard alloy and ceramic material processing

- Hard stone and concrete surface treatment

- High-hardness coating removal

- Surface preparation requiring high roughness

Characteristics & Advantages:

- 100% natural organic material, environmentally friendly and non-toxic

- Extremely gentle surface treatment method

- Will not damage substrate surface

- Good adsorption ability, can remove oil stains

Typical Applications:

- Soft metal surface cleaning

- Wood and composite material treatment

- Precision electronic component cleaning

- Historical artifact and artwork restoration

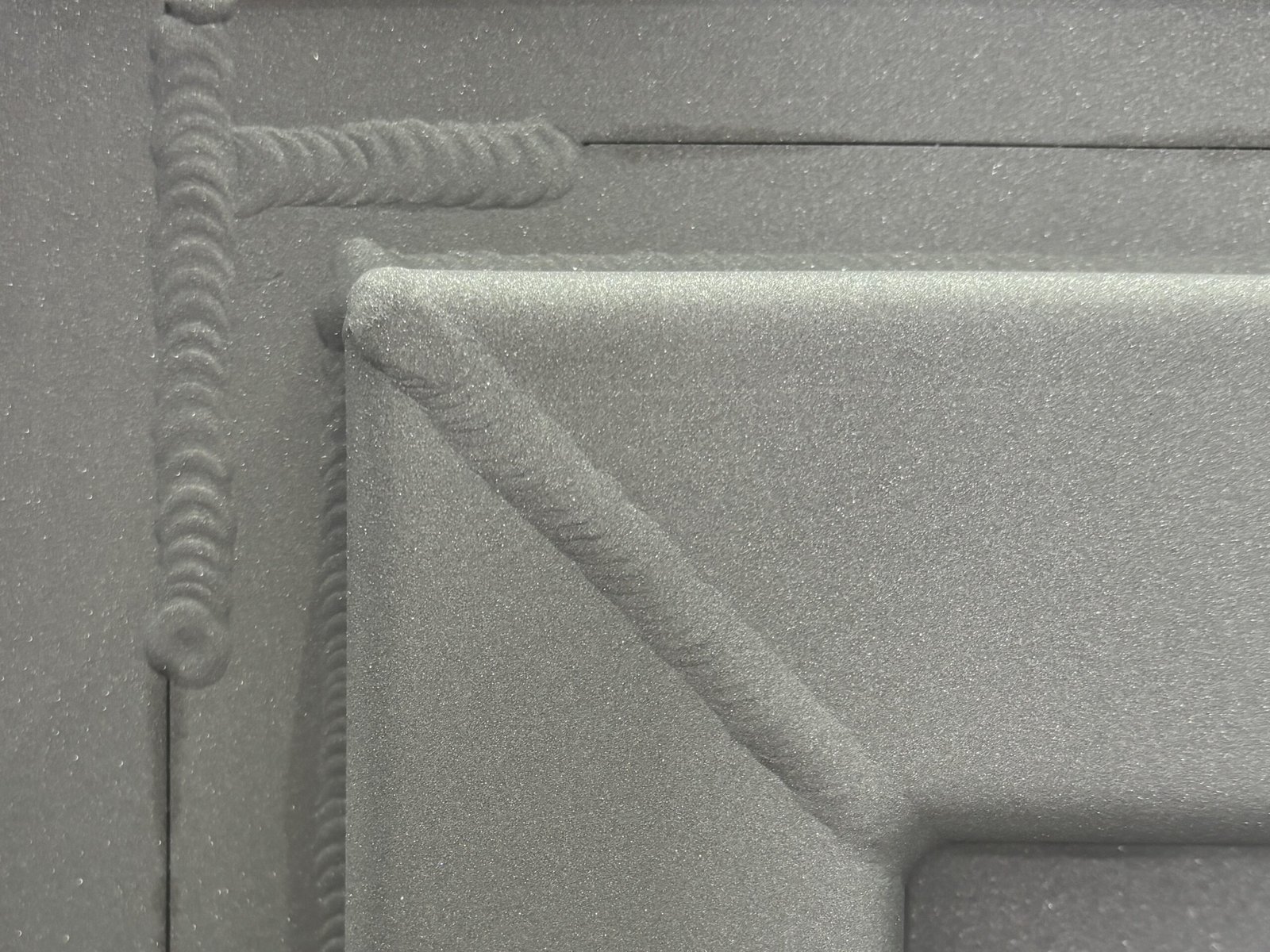

Example of Bead Blasting

Before Bead Blasting

After Bead Blasting

Request a quoteBlasting Process Optimization Control System

Precise Parameter Control

Our blasting process uses a computer control system to precisely regulate key parameters, ensuring optimal results:

- Blasting Pressure Control: Adjustable range of 0.2-0.7MPa, with precision of ±0.01MPa

- Blasting Distance Optimization: Automatically adjusts optimal distance between 10-30cm according to workpiece type

- Blasting Angle Setting: Adjustable from 30°-90°, adapting to different surface treatment requirements

- Precise Blasting Duration Control: PLC system ensures second-level precision processing time

- Media Grit Size Selection: Full series available from very fine (#220) to coarse (#20)

Quality Control Process

We implement a strict three-stage quality control process to ensure each blasting project meets client expectations:

1. Pre-process Quality Check:

- Material analysis and parameter matching

- Sample testing and verification

- Process parameter determination and recording

2. In-process Quality Monitoring:

- Real-time parameter monitoring and adjustment

- Online surface quality detection

- Multi-point sampling Ra value verification

3. Finished Product Quality Verification:

- Surface roughness (Ra) precise measurement

- Visual uniformity inspection

- Customer specification compliance confirmation

Precise Control of Blasting Surface Roughness

Industry-Standard Roughness Control Capabilities

We can precisely control the surface roughness after blasting, meeting the most stringent industry requirements:

| Roughness Level | Ra Value Range(μm) | Typical Applications | Recommended Blasting Media |

| Ultra-fine | 0.1-0.3 | Optical elements, reflectors | Glass beads #180 – #220 |

| Fine | 0.3-0.8 | Semiconductor parts,precision electronics | Glass beads #100 – #150 |

| Standard | 0.8-1.5 | Medical devices,precision machinery | Glass beads/Ceramic beads #80 – #100 |

| Medium | 1.5-3.0 | Automotive parts,general machinery | Aluminum oxide/Ceramic grit #60 – #80 |

| Coarse | 3.0-5.0 | Heavy industry,marine components | Steel shot/Aluminum oxide #40 – #60 |

Advanced Measurement and Verification

We use state-of-the-art measurement technologies to ensure surface quality:

- Contact Roughness Tester: Can measure multiple parameters such as Ra, Rz, Rmax, with precision up to 0.01μm

- 3D Optical Profilometer: Non-contact measurement suitable for precision and fragile surfaces

- SEM Microscopic Analysis: Microstructure verification, ensuring surface quality consistency

- Fully Digital Recording System: Traceability of parameters and results for each batch of products

Industry-Customized Blasting Solutions

Semiconductor Equipment Component Processing

1. Special Requirements: Extremely low particle residue, no metal contamination

2. Recommended Process: Glass bead blasting (#80-#120), Ra value controlled at 0.3-0.8μm

3. Dedicated Equipment: High-purity closed system preventing cross-contamination

Quality Standards: Compliant with SEMI standards, 100% full inspection

Marine and Heavy Industry Component Processing

1. Special Requirements: Extreme corrosion resistance, high-adhesion substrate preparation

2. Recommended Process: Steel shot blasting (#40-#60), Ra value controlled at 2.0-4.0μm

3. Dedicated Equipment: Large blasting chamber capable of processing workpieces up to 3000×1500×1000mm

4. Quality Standards: Compliant with SSPC-SP and ISO 8501 standards

Automotive Precision Component Processing

1. Special Requirements: Precise dimensional control, surface uniformity, batch consistency

2. Recommended Process: Aluminum oxide blasting (#60-#100), Ra value controlled at 1.5-3.0μm

3. Dedicated Equipment: Automated conveyor line ensuring consistency in large batch processing

4. Quality Standards: Compliant with IATF 16949 and VDA requirements

Aerospace Component Surface Treatment

1. Special Requirements: Fatigue strength enhancement, stress relief, surface hardening

2. Recommended Process: Ceramic bead blasting (#60-#80), Ra value controlled at 1.0-2.5μm

3. Dedicated Equipment: Multi-axis automated blasting system ensuring uniform processing of complex parts

4. Quality Standards: Compliant with AS9100 and NADCAP requirements

Medical Device Precision Processing

1. Special Requirements: Biocompatibility, no residue, surface uniformity

2. Recommended Process: Ceramic bead blasting, Ra value precisely controlled at 0.2-0.6μm

3. Dedicated Equipment: Medical-grade sterile processing environment

4. Quality Standards: Compliant with FDA and ISO 13485 standards

Precision Machining, Unlimited Possibilities

Contact Us Now For A Free Consultation

Share your project requirements with us and let our expert team provide high-precision solutions for your challenges. 20 years of exceptional craftsmanship, dedicated to your next successful project. Contact us today to start our partnership journey.