Design for Manufacturability (DFM) simplifies the manufacturing process and cuts costs. It's crucial for precision fields like CNC machining and 3D printing.

Design for Manufacturability (DFM) focuses on optimizing manufacturing by improving part design. This proactive approach reduces expenses and complexity while enhancing product performance and quality.

Delving into DFM reveals strategies to streamline production processes. Understanding DFM could transform how parts are produced, particularly in industries relying on precision manufacturing technologies.

What is Design for Manufacturability (DFM) and How to Implement It?

Imagine simplifying your production, cutting costs, and boosting efficiency. DFM, an engineering strategy, can achieve precisely that.

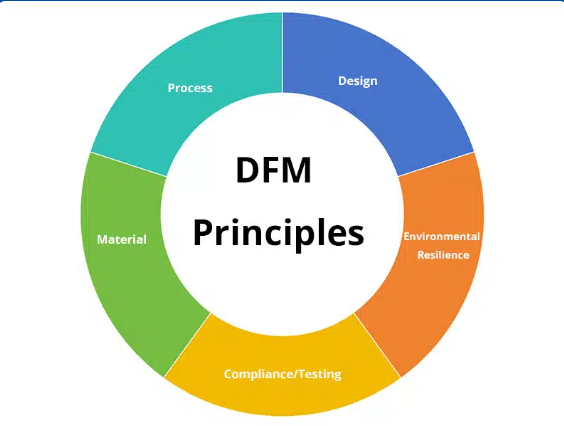

DFM ensures parts are designed to minimize production woes and maximize efficiency. This involves keen attention to process, design, material, environment, and compliance factors.

Designing for Manufacturing Success

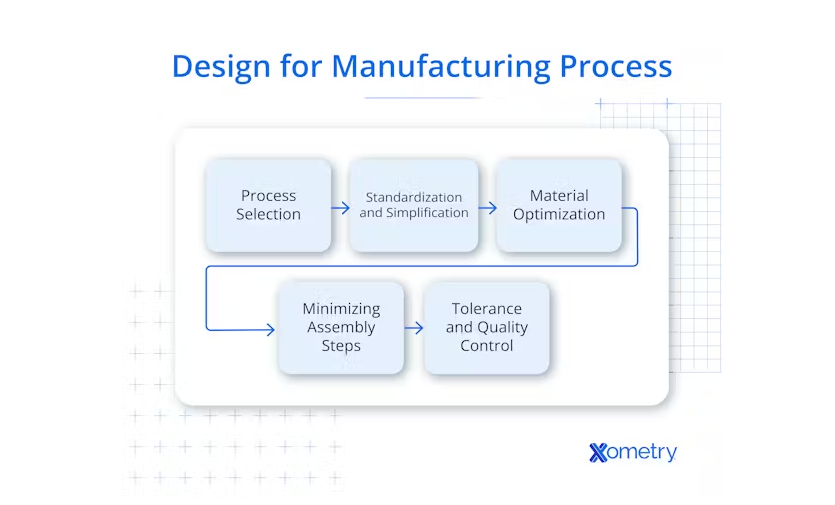

Implementing DFM involves integrating knowledge of manufacturing capabilities into the design phase. First, understand the factory's capabilities and limitations, identifying materials best suited to production goals. Collaboration between design and manufacturing teams fosters cohesive efforts, ensuring the part is suitable for the equipment and processes in use. Utilize CAD tools for virtual prototypes and simulations, predicting potential manufacturing issues before real-world production begins. Regular feedback and iteration are vital; refining designs based on manufacturing feedback reduces errors and improves outcomes.

How Does Design for Manufacturability Optimize Your Manufacturing Process?

Manufacturing inefficiencies can inflate costs and slow production. DFM tackles these issues head-on.

By focusing on design that aligns with manufacturing capabilities, DFM eliminates unnecessary complexities and enhances production speed and product quality.

Streamlined Production

The optimization begins with identifying potential bottlenecks in the production process, where DFM can play a strategic role. Effective DFM entails analyzing designs to ensure compatibility with existing machinery and processes. Evaluation should consider ease of assembly, parts integration, and potential material handling obstacles. Restructuring complex designs for simplicity allows faster, cost-effective production. DFM fosters an environment where collaboration between engineers and machinists leads to innovative solutions that balance design ambition with manufacturing realities.

What Are the Key Factors for Successful DFM Implementation?

Navigating DFM requires understanding vital elements that drive success.

Careful consideration of design, materials, and processes forms a strong foundation for effective DFM practice.

Successful implementation demands thorough consideration of several key factors:

Process Compatibility: Design elements should align with machine capabilities—reducing trial-and-error and ensuring speedy production.

Material Selection: Choose materials based on both performance and manufacturability, balancing quality with production ease.

Design Simplicity: Streamline complexity in designs; eliminate unnecessary features that complicate manufacturing.

Environmental Considerations: Factor in environmental impact and compliance standards throughout the design.

Collaboration: Foster communication among design and manufacturing teams, ensuring cohesive goals.

Encouraging open dialogue with stakeholders and integrating feedback loops leads to continuous improvement in DFM practices. Regular reviews ensure designs remain cost-efficient and aligned with production capabilities.

Conclusion

Design for Manufacturability optimizes production by aligning design with manufacturing capabilities, simplifying processes, and enhancing product quality, especially in precision manufacturing industries.