Precision-machined parts often face a critical problem: they need protection from corrosion and wear while maintaining dimensional accuracy. Many standard coatings fail to deliver both, compromising either protection or precision.

Orange peel powder coating solves this dilemma by providing exceptional durability without sacrificing component accuracy. This specialized finish creates a subtle textured surface that enhances wear resistance, masks minor machining imperfections, and offers superior corrosion protection—all while maintaining critical tolerances on precision parts.

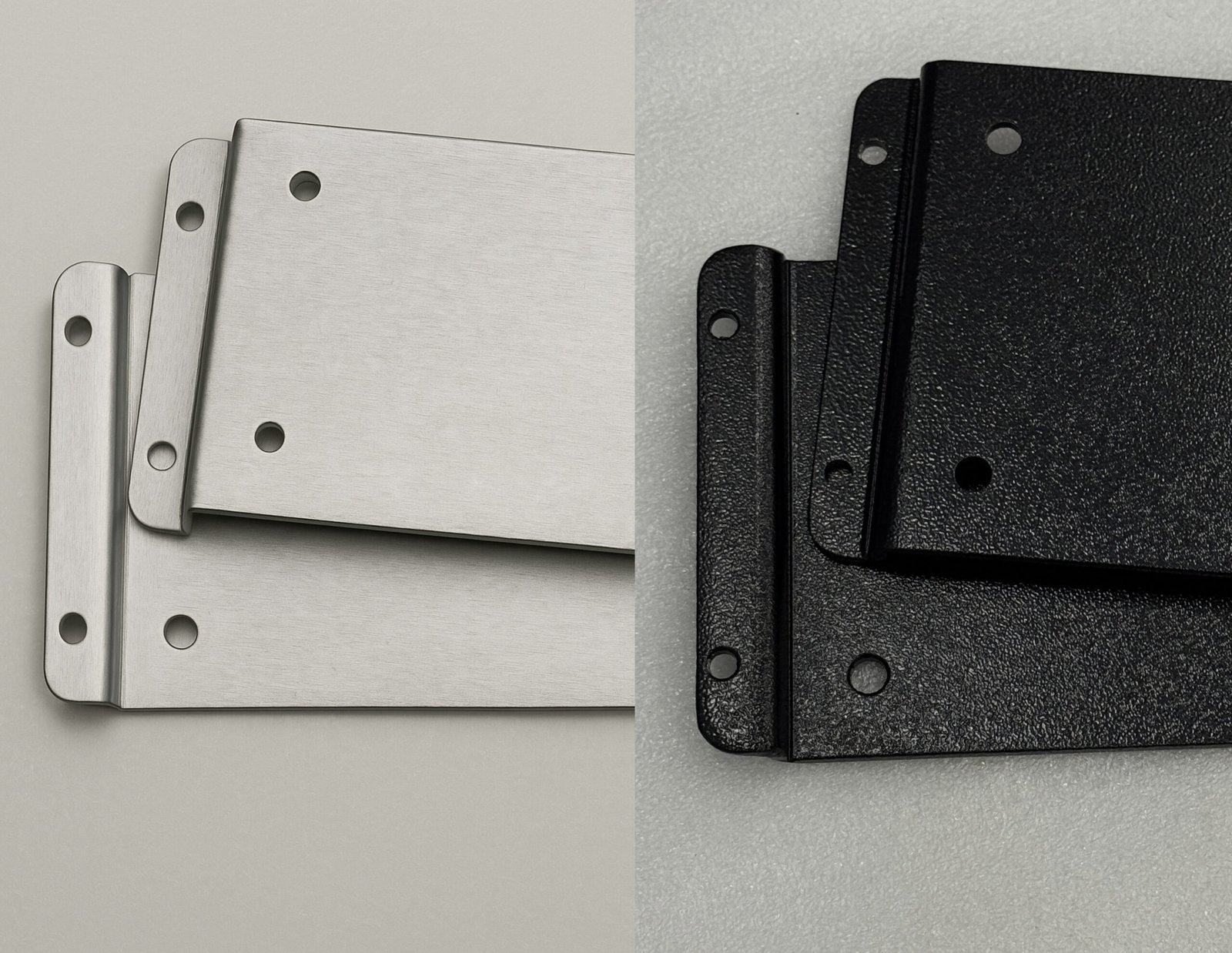

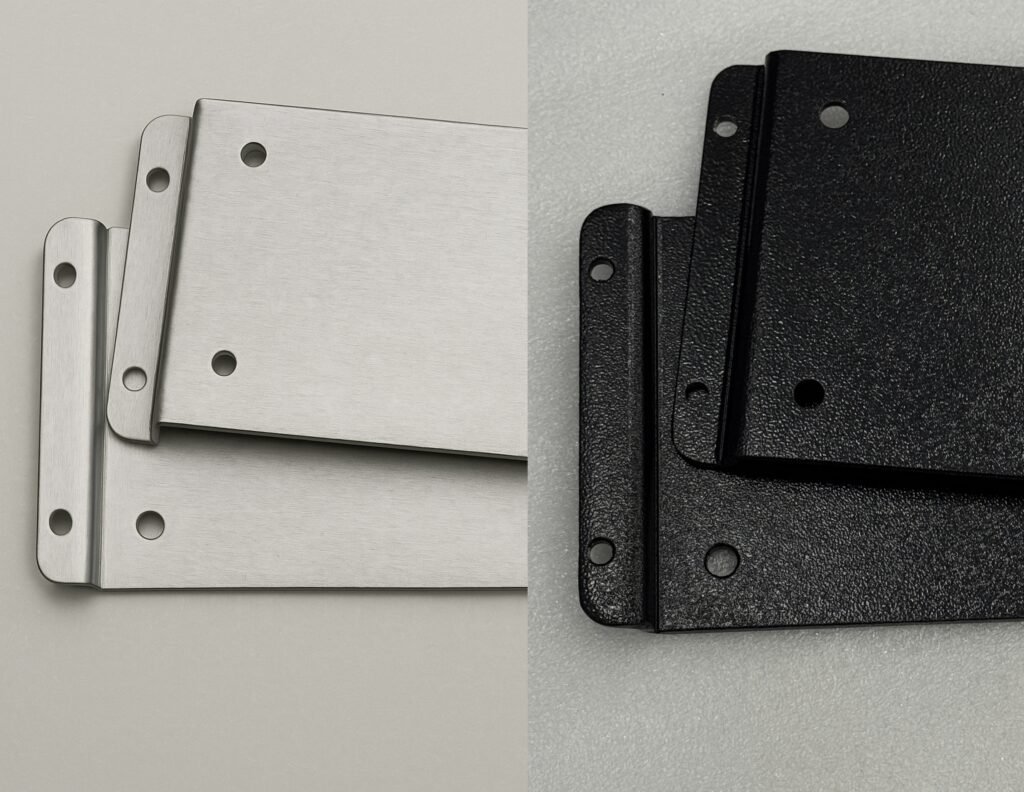

CNC-machined components with orange peel finish

As a CNC machining provider with years of experience applying specialized finishes to critical components, I've seen firsthand how the right coating can dramatically extend part life and improve performance. Orange peel powder coating has become one of our most requested finishes for good reason—it combines practical protection with aesthetic appeal in ways that benefit numerous industries.

What exactly is orange peel powder coating, and how does it differ from standard finishes?

Clients often ask me about finishes that look great but won't chip or fade quickly. Standard paint options typically disappoint, either wearing away too soon or adding unwanted thickness that affects part fit.

Orange peel powder coating is a specialized electrostatic application process that creates a textured surface resembling citrus peel. Unlike smooth finishes, it intentionally forms subtle surface variations that distribute wear more evenly while hiding minor defects. The coating is applied as dry powder, then heat-cured to form a durable polymer bond without using solvents.

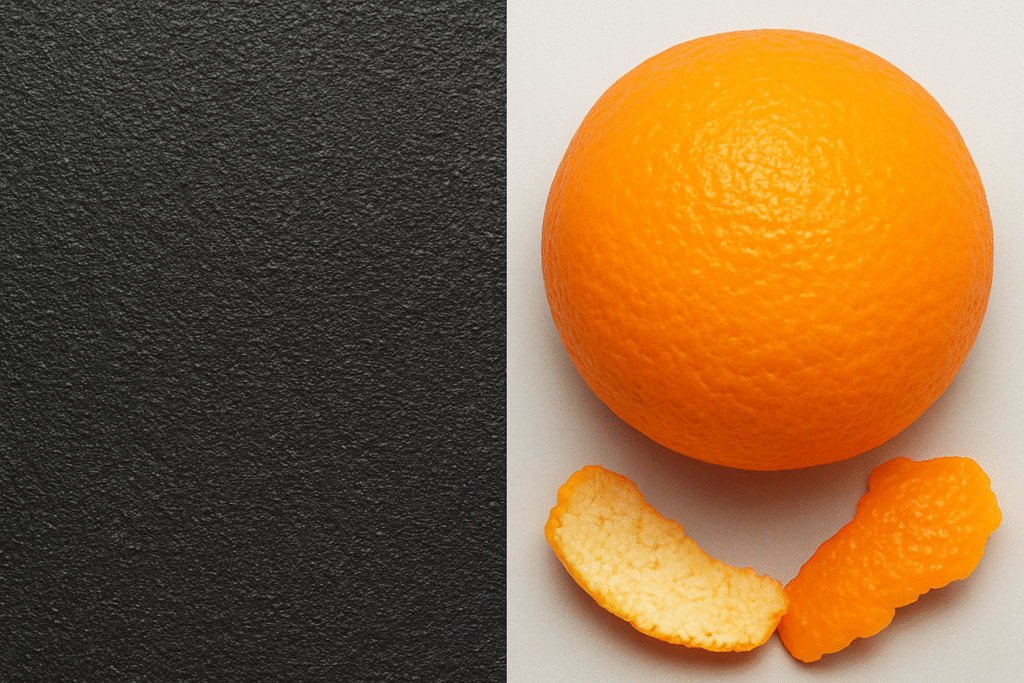

Detailed texture of orange peel powder coating

The name "orange peel" derives from its visual and tactile similarity to citrus fruit skin. This texture occurs when the powder coating doesn't completely level during the curing process, creating a distinctive pattern of small peaks and valleys across the surface. Unlike standard powder coatings that strive for perfect smoothness, the orange peel finish intentionally maintains this texture.

The differences between orange peel and standard finishes go beyond appearances. Standard smooth powder coatings aim for a glass-like surface but can highlight imperfections in the substrate. Any minor scratches or machining marks become more visible under a perfectly smooth coating. Orange peel texture, however, creates visual "noise" that effectively masks these minor defects.

From a manufacturing perspective, orange peel finishes are also more forgiving during application. The textured nature means minor variations in coating thickness or application technique don't create visible defects the way they would in mirror-smooth finishes. This results in higher yield rates in production and fewer rejected parts, which translates to cost savings for both manufacturer and customer.

Additionally, the orange peel texture provides improved grip for components that will be handled frequently. The slight texture increases friction compared to smooth coatings, making parts easier to grasp and less likely to slip during assembly or maintenance operations.

Why do certain industries prefer an orange peel texture for functional components?

I recently worked with an automotive client who kept experiencing failures with smooth-coated engine components. The parts looked perfect but failed prematurely in high-vibration environments where micro-abrasions quickly degraded the finish.

Orange peel texture is preferred in industries like automotive, aerospace, and industrial equipment because it provides superior wear resistance. The textured surface distributes impact and abrasion across multiple points rather than concentrating force in one area, significantly extending part life in high-stress applications.

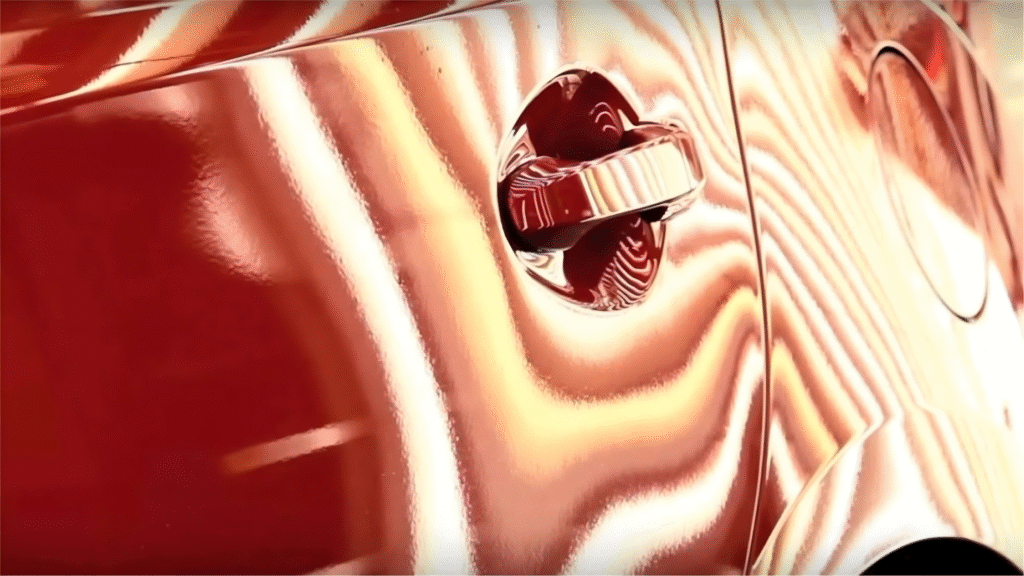

Automotive parts with an orange peel finish

The distinctive benefits of orange peel texture make it particularly valuable for specific applications across various industries. In the automotive sector, this finish is commonly specified for underhood components, chassis parts, and suspension elements where both corrosion resistance and durability are critical. The textured surface helps prevent the coating from chipping when small stones or road debris impact these parts.

For aerospace applications, orange peel finishes offer weight advantages over other protective methods. The powder coating process allows for precise thickness control, typically between 50-100 microns, providing necessary protection without adding excessive weight to components where every gram matters for fuel efficiency and performance.

Industrial equipment manufacturers value orange peel texture for machine frames, control panels, and external components exposed to harsh environments. The finish maintains its appearance longer than smooth coatings when subjected to regular cleaning, chemical exposure, or outdoor conditions.

Consumer product manufacturers often select orange peel finishes for items that will be handled frequently. Beyond the practical grip benefits, the texture helps hide fingerprints and minor scratches that would be immediately visible on glossy surfaces. This keeps products looking newer for longer, enhancing brand perception and customer satisfaction.

Medical equipment benefits from orange peel finishes due to their excellent cleanability, combined with durability. The slight texture doesn't trap contaminants the way deeper textures might, yet offers improved chemical resistance compared to smooth finishes, making these components easier to sanitize repeatedly without degrading the protective coating.

How does the orange peel finish impact the durability of machined aluminum and steel parts?

Last month, our corrosion testing lab compared identical aluminum brackets with different finishes. After 500 hours of salt spray exposure, the orange peel-coated parts showed virtually no deterioration, while standard painted parts had begun to show significant corrosion.

Orange peel powder coating creates a chemical bond with metal substrates that's substantially stronger than traditional paint adhesion. This molecular-level bond prevents moisture penetration even when the part is scratched or impacted, providing 3-5 times longer corrosion protection for both aluminum and steel components.

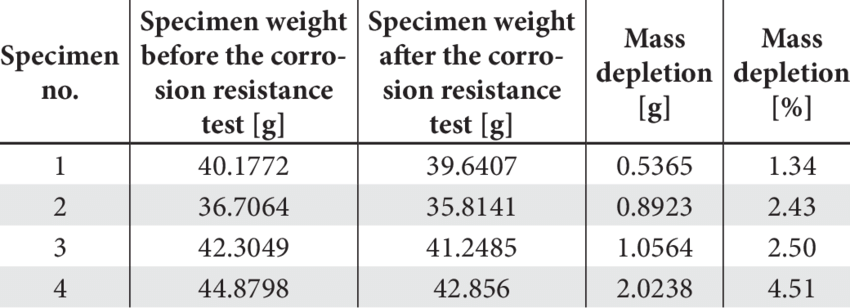

Corrosion resistance test results

The enhanced durability of orange peel powder coating stems from multiple factors beyond just the surface texture. The application process itself contributes significantly to the coating's performance advantages. Unlike liquid paints that contain solvents that must evaporate, powder coating is applied as a dry substance that undergoes a complete chemical transformation during curing.

For aluminum components, this process is particularly beneficial. Aluminum naturally forms an oxide layer that can interfere with coating adhesion. During powder coating application, the pretreatment process removes this oxide layer, and the electrostatic application ensures complete coverage of complex geometries. When heat-cured, the powder forms a continuous protective layer that follows the contours of the part without thinning at edges or corners – common failure points for traditional finishes.

Steel components benefit similarly but face different challenges. Steel is susceptible to flash rusting between cleaning and coating steps. The powder coating process minimizes this risk through its rapid application and curing sequence. The resulting orange peel finish on steel parts provides not just corrosion protection but also significant impact resistance. When a coated steel part experiences impact, the textured surface helps dissipate energy across a wider area rather than concentrating force at a single point, reducing the likelihood of coating failure.

Temperature resistance represents another durability advantage. Standard orange peel powder coatings maintain their protective properties in temperatures ranging from -60°C to 200°C without cracking or delaminating. This makes them suitable for components exposed to extreme environments, from aerospace applications to industrial machinery operating in varied climates.

UV resistance further enhances long-term durability. Unlike many liquid paints that degrade and fade with sun exposure, properly formulated powder coatings with orange peel texture retain their color and protective properties for years of outdoor use, making them ideal for exterior components on vehicles, equipment, and architectural applications.

Which technical specifications should you consider when ordering orange peel powder-coated components?

When a medical device manufacturer approached us about coating precision components, they didn't specify coating thickness or texture depth. This led to rejected parts that didn't meet their assembly requirements, costing valuable time and materials.

When ordering orange peel powder-coated parts, you should specify coating thickness (typically 2-4 mils), texture depth (measured in gloss units), and environmental performance requirements (UV, salt spray hours, impact resistance). Providing these specifications ensures the coating meets both aesthetic and functional requirements for your application.

Measuring orange peel coating specifications

The technical specifications for orange peel powder coating deserve careful consideration to ensure optimal performance in your specific application. Beyond the basics of thickness and texture depth, several other factors can significantly impact the success of your coated components.

Color consistency becomes particularly important for visible parts that must match across assemblies. The nature of orange peel texture can affect color perception, making it essential to establish acceptable color variation ranges using standard measurement systems like RAL, Pantone, or Lab* color coordinates. When ordering components that will be used together, specify that they should be coated in the same batch to minimize variation.

Chemical resistance requirements should be clearly defined based on the operating environment. Different powder coating formulations offer varying resistance to specific chemicals, oils, fuels, cleaning agents, and solvents. For example, polyester-based powders typically provide better UV stability for outdoor applications, while epoxy-based coatings offer superior chemical resistance for industrial environments.

Electrical properties may also be relevant for certain applications. Some powder coatings can be formulated to be electrically conductive or dissipative, while others provide electrical insulation. If your component has specific electrical requirements, these must be specified when ordering.

Edge coverage deserves special attention for precision-machined parts with sharp edges or complex geometries. The electrostatic application process can sometimes result in a thinner coating at edges and corners. For critical applications, specify minimum edge coverage requirements or request edge rounding prior to coating application.

Testing and certification requirements should be clearly communicated when ordering. If your application requires specific performance standards like AAMA 2604/2605 for architectural applications, automotive specifications like Ford WSS-M2P100-D, or medical-grade certifications, these must be specified upfront to ensure appropriate powder formulations and quality control processes are used.

Finally, masking requirements for areas that must remain uncoated (like threaded holes, mating surfaces, or electrical contact points) need a detailed specification. Provide engineering drawings clearly indicating which surfaces must be protected during the coating process to maintain critical dimensions and functionality.

Conclusion

Orange peel powder coating offers the ideal balance of durability, aesthetics, and functional protection for precision CNC-machined components. By understanding its unique properties and specifying the right parameters, you'll maximize component performance and lifespan in demanding applications.