Good Luck Starting Work 2025

A Fresh Start—Let’s Build a Successful Year Together! We’re back and ready to kick off an exciting new year! With renewed enthusiasm and a commitment

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

A Fresh Start—Let’s Build a Successful Year Together! We’re back and ready to kick off an exciting new year! With renewed enthusiasm and a commitment

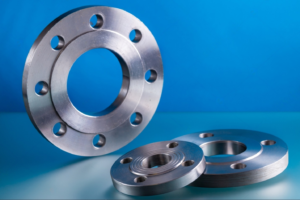

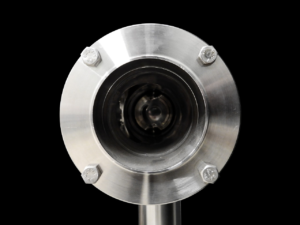

Flanges are among the most important parts of piping systems, which ensure a tight and reliable joining of pipes, valves, pumps, and other pieces of equipment. Their main application is to provide tight connections with easy access for maintenance, cleaning, inspection, or modifications of a system. Flanged joints are formed by bolting two flanges together with a gasket placed between them to provide tight sealing to prevent leakage.

TIG welding, also known as GTAW, has become a universal joining method through which several major industries operate in regard to its precision and the versatility of working with it. The processes are employed to weld longitudinal seams in thin-wall stainless steel and alloy pressure pipes, and in continuous strip mills, where a lack of filler metal is often preferred. On the contrary, it also employs the presence of filler metal for thicker walled pipes and tubing in all welding positions inside the power generation, chemical, and petroleum industries.

In high-precision sectors, vacuum welding is a game-changing technique that provides unmatched advantages like excellent weld quality, little contamination, and the capacity to fuse materials that are challenging to weld under typical circumstances. Particularly in crucial applications like aerospace, electronics, medical devices, and energy systems, vacuum welding guarantees the dependability and durability of welded components by establishing a regulated, contaminant-free environment.

Happy Chinese New Year!

Flanges are critical components in industrial piping systems. Choosing the right products promotes the safety and efficiency of operations. Getting a reputable flange and accessories supplier is a possibility.

When you know how to approach the market, you can guarantee quality. Always consider the materials, sizes, dimensions, and durability. You need products that ensure safe piping and prolonged application. With this information, you can buy precision-manufactured flanges.

Landing gear system production certainly has shifted as an outcome of CNC machining, which provides unmatched accuracy, productivity, and flexibility to satisfy the exacting requirements of contemporary aerospace engineering. CNC machining will remain at the forefront of developing more dependable, effective, and innovative landing gear systems through continued developments.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.