How Should Rough and Finish Machining Be Sequenced for Optimal Results?

Proper sequencing of rough and finish machining operations dramatically impacts part quality, production efficiency, and costs.

Drawing from our 20+ years of precision machining experience, we share practical insights to help you overcome technical challenges in complex parts manufacturing. From material selection to process optimization, we empower your procurement decisions with professional expertise and confidence.

Proper sequencing of rough and finish machining operations dramatically impacts part quality, production efficiency, and costs.

Successful thin-walled machining requires a comprehensive approach to support techniques. By carefully selecting the right support methods for your specific material and application, you can achieve exceptional quality while minimizing scrap rates and production costs.

Moreover, modern advancements like CNC integration and advanced coatings have made forming knives more durable and accurate.

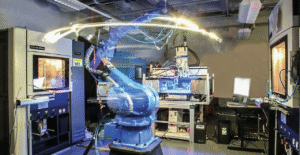

The most competitive companies will be those who strike a balance between creativity and precision, utilizing the established advantages of CNC machining while embracing digital transformation for the future of smart manufacturing, as research and technology continue to progress.

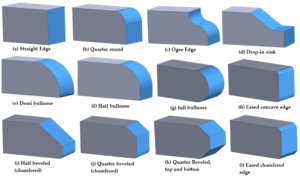

Achieving excellent surface finish on curved surfaces requires balancing tool path direction, step-over distance, and tool geometry.

Thermal expansion is one of the most influential yet controllable factors in CNC machining of tight-tolerance parts.

Burrs may seem like minor machining imperfections, but their consequences can be significant. They affect assembly accuracy, surface integrity, and long-term reliability of components.

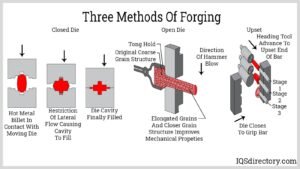

Forged materials deliver superior performance through enhanced grain structure, eliminated porosity, and directional strength—making them ideal for critical applications where failure isn’t an option.

Hydrostatic pressure testing is essential for ensuring component integrity and safety.

Tool nose radius compensation stands at the heart of precision CNC turning. It bridges the gap between programmed geometry and the real-world behavior of cutting tools, ensuring that every contour, diameter, and surface matches design intent.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.