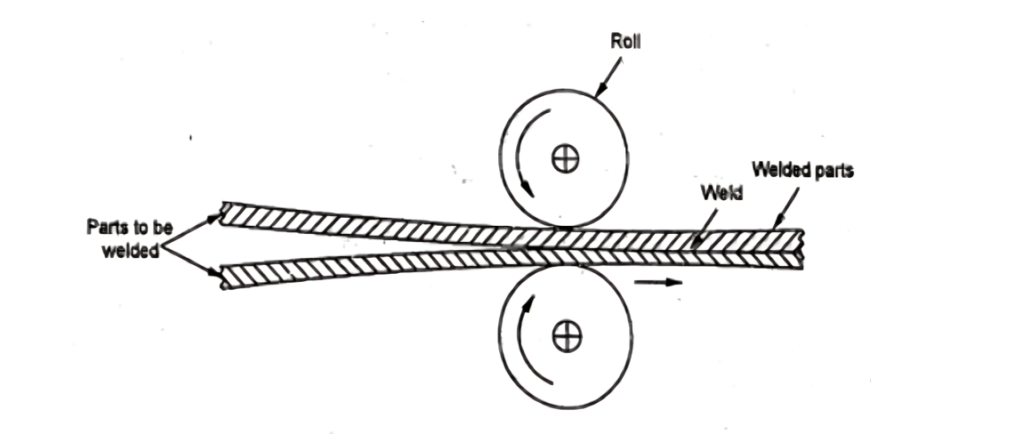

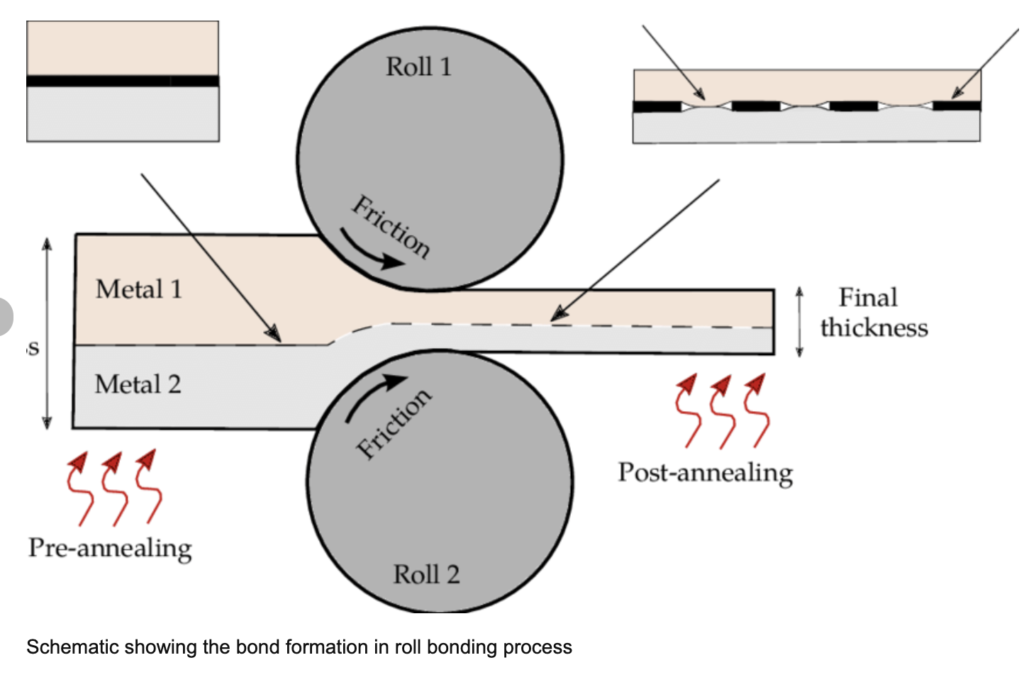

The roll-welding process, also called roll bonding, is a welding technique that joins two or more metal layers as they pass through a set of rollers, applying heat and pressure in their solid state. This method differs from traditional techniques that involve melting the metal. Instead, using mechanical pressure (and sometimes heat can be added), roll welding smashes them together to form its own metallurgical bond.

Key Features of Roll Welding

- Solid-State Process: Solid-State Process: In roll welding, the material remains in a solid state and retains its original properties, minimizing the risk of defects such as porosity or cracking. This solid-state process avoids the formation of new, weaker grain boundaries that can occur during melting.

- Pressure Application: The core of the roll welding process is the pressure applied by the rolls. This pressure causes atoms at the metal surfaces to diffuse into each other, forming a bond that can be as strong as the original materials.

- Heat Generation: Depending on the materials and desired product, it may be necessary to apply heat in order to facilitate roll welding. This heat can be generated by friction between metal and roller surfaces or the heat can be supplied externally.

Types of Roll Welding

You can select a roll welding method to suit your requirements

- Cold Roll Welding: This method involves welding at room temperature, relying solely on pressure to join the metals. It is particularly suitable for materials that bond without the need for heat treatment.

- Hot Roll Welding: In this method, the metal is heated before rolling, making it suitable for materials that cannot be welded effectively at lower temperatures.

- Explosion Roll Welding: In this method, metals are joined by an explosive force, creating a bond that can be as strong as the parent materials.

Roll-Welded Heat Exchangers

Heat exchangers are an important component in a variety of industries, from the production of power in an industrial district to air conditioning for buildings. Its capacity to produce strong, durable, and thermally efficient joints between metals gives roll welding a central role in the manufacturing of heat exchangers.

Manufacturing procedure

In the manufacturing of roll-welded heat exchangers, one typically starts with thin metal sheets--such as stainless steel and aluminum. Bypassing these sheets through rollers, you can bind multiple layers together, thus shaping the heart of your heat exchanger. The result is a structure that is as efficient in transferring heat as it is able to cope under conditions of high pressure and temperature levels.

Advantages of Roll-Welded Heat Exchangers

- Greater Durability: with roll welding, the resultant bonds are exceedingly solid, meaning that you can rely on your heat exchangers to withstand tough industrial conditions.

- Higher Thermal Efficiency: the heat transfer efficiency of the exchangers is significantly increased as roll welding makes it possible to produce intimately bonded layers.

- Corrosion Resistance: by using appropriate materials, such as cladding a steel core with corrosion-resistant alloys, you can manufacture heat exchangers able to perform even in highly corrosive environments.

Cladding of Metals by Strip Roll

Cladding improves the wear resistance or functionality of welding by placing material on one side.

Strip Roll Cladding Procedure

To start your strip roll cladding procedure meticulously prepare the surfaces of both base metal and cladding strip. After aligning them perfectly through a series of rolls maintained at high pressure, the design of this action is to create a metallurgical bond between the strip and the substrate.

Applications of Strip Roll Cladding

- Corrosion Protection: The service life of materials can extend significantly if a base metal is clad in corrosion-resistant alloy. Such materials are particularly suitable for use in inhospitable environments.

- Aesthetic Enhancement: In sectors where looks are a major factor, such as consumer electronics or architecture, strips may be used to add a layer of decor without affecting the workability of the material.

- Cost Efficiency: Several times less expensive materials are clad with a more expensive coating only where needed, thus lowering general production costs while retaining excellent properties for particular uses.

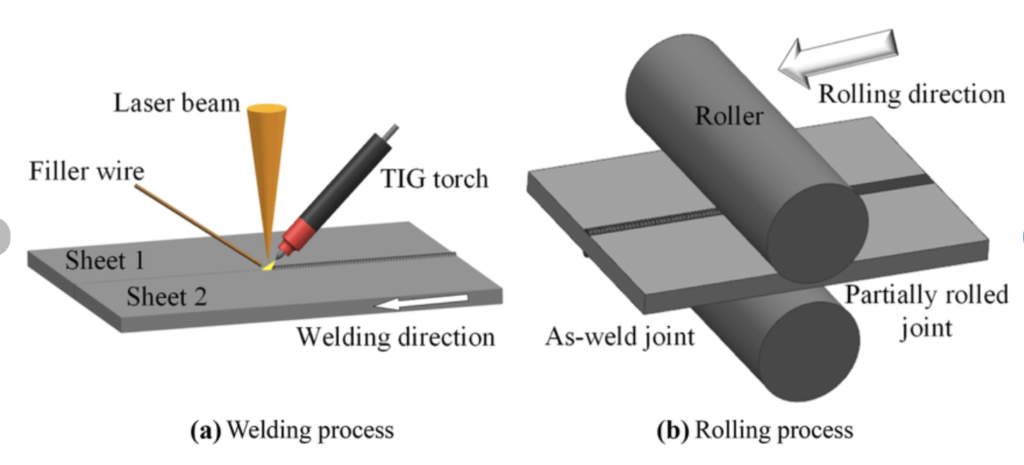

Laser Roll Welding

The more the technology advances, the more accurate and fine the control of metalworking techniques can become. Laser roll welding is a big step forward. It combines the benefits of conventional roll welding with the accuracy of modern laser technology.

Working Principle of Laser Roll Welding

A laser beam is directed at the metal surfaces, as they pass through the rollers. The laser provides a focused heat source that melts only a thin area of material, improving the bonding process to apply pressure. This method allows for the most precise, high-quality welds on fragile or thin materials.

Advantages of Laser Roll Welding

- Precision: With laser roll welding, heat input can be controlled accurately, which means there is less chance of defects such as weld shrinkage and warping.

- Welding Dissimilar Metals: This method is particularly effective when you need to join metals of different melting points or heat-carrying capacities. The laser allows for localized heating, forming strong bonds without having an effect on the overall material.

- Speed and Efficiency: Laser roll welding is swifter than many traditional welding processes: exactly suited to large-scale manufacturing.

Laser Roll Welding of Dissimilar Metals

It is a difficult job to weld metals that are different from one another. In roll welding with laser, however, this difficulty can be avoided very easily, just with precision and reliability.

Dissimilar Metal Welding Challenges

- Different Melting Points: As an example of its range of melting points, aluminum and steel are metals so different that they can hardly be welded together (if welded at all) without causing shortcomings in the joint structure.

- Rate of Thermal Expansion: As dissimilar metals expand at different rates, they are susceptible to stress and cracking during the welding process.

- Chemical Compatibility: When metals are welded together, some metals may react with one another chemically; this may result in brittle or weak joints.

Solutions Offered by Laser Roll Welding

Laser roll welding affects the very spot where the heat is required. This makes it possible to weld dissimilar metals with no fear of spreading melting or cold development stress. By directing the concentrated energy of the laser in a line perpendicular to the axis, thermal distortion is minimized. The rollers we use as a mechanical pressure assures that there will be no cracks or weak spots.

This is especially suitable in applications such as electronics, where you may want to join metals which are very far apart on the scale of electrical conductance.

Advantages of Roll Welding

When you choose to roll weld, you get a number of key benefits that make this process very worthwhile for different applications:

- Strong, Durable Bonds: Often stronger than what might otherwise result from regular welding techniques, roll welding produces reliable longevity in final products.

- Versatility: Roll welding is suitable for welding a wide range of metals, including metals difficult-assembled using other ways.

- Cost-Effective Production: Without the need for filler materials and the associated reduced incidence of defects, roll welding can also save on production costs.

- Environmental Advantages: Roll welding is a solid-state process that produces little emissions and uses less energy than most other welding methods.

- Accuracy: Accurate when combined with laser technology and regardless of the size of rolls being moved, roll welding can bring in precise control, leaving as little waste as possible where good quality welds are concerned.

Limitations Of Roll Welding

But as with any process roll welding does have its limitations:

- The Costs Of Equipment: Roll welding machinery is expensive, especially when utilizing advanced technologies like lasers.

- Compatibility With Material: Roll welding can join together many different kinds of metal. However, there are still some combinations that present a challenge, particularly those whose properties differ greatly from one another.

- Restrictions On Thickness: Roll welding is best conducted using thin materials. Joining very thick metal, however, may involve several steps or alternatives.

- Surface Preparation: In order to make a metal bond strong, the surfaces of the metals must be clean and completely unadulterated. To make this happen, careful treatment is essential.

Applications For Roll Welding

Roll welding is a universal technique with applications in many industries.

- Aerospace: In the field of aerospace roll welding plays a critical role in creating lightweight, high-strength components necessary for aircraft and spacecraft, where the integrity of the material is very important.

- Automotive Industry: In the car industry roll welding is used to form components like heat exchangers, contrasted parts, and cladding materials.

- Construction: Roll welding creates a sound way of developing hard-wearing conform material, roofing matter, and other construction components.

- Electronics: In the electronics industry, roll welding is an invaluable asset for joining dissimilar metals in electronic components, so as to guarantee reliable connections and better performance.

- Energy: In the energy industry roll welding is used for fabricating heat exchangers, cladding on pipelines as well as many other components that experience harsh conditions.

Roll Solid State Welding for Unusual Applications

In addition to traditional industrial applications, roll welding has many unconventional uses. Everywhere you turn, it's being applied to various specialized applications in new and different fields.

● Medical Devices

In the medical industry, roll welding is used to build complex, high-precision components for devices that require absolutely reliable performance and biocompatibility. Because of the solid-state nature of roll welding, unlike in traditional forging operations, these components remain free from contaminants and defects.

● Artistic Creations

Artists and designers alike have adopted roll welding to construct original metal sculptures and architectural features. Via mixed-metal bonds, they are able to achieve effects that would be hard or impossible otherwise. These result in spectacular visual and structural pieces.

● Research and Development

In research and development, roll welding is being used to push the boundaries of materials and processes. Researchers can create materials specifically tailored to their needs, with unique properties that are unobtainable using conventional methods.

Conclusion

Roll welding is a method for joining metals essential to modern manufacturing. One can considerably improve the quality and working properties of their projects by understanding their principles and applications. Lastly, while there may be some restrictions, roll welding's merits far outweigh the disadvantages.

Are you prepared to build up your construction projects? Our expertise in roll welding can help provide you with results that are simply ahead of anything else around, contact us today and learn how.