Imagine your equipment failing because of a tiny welding error. Welding undercut can be a critical issue, especially in vacuum applications.

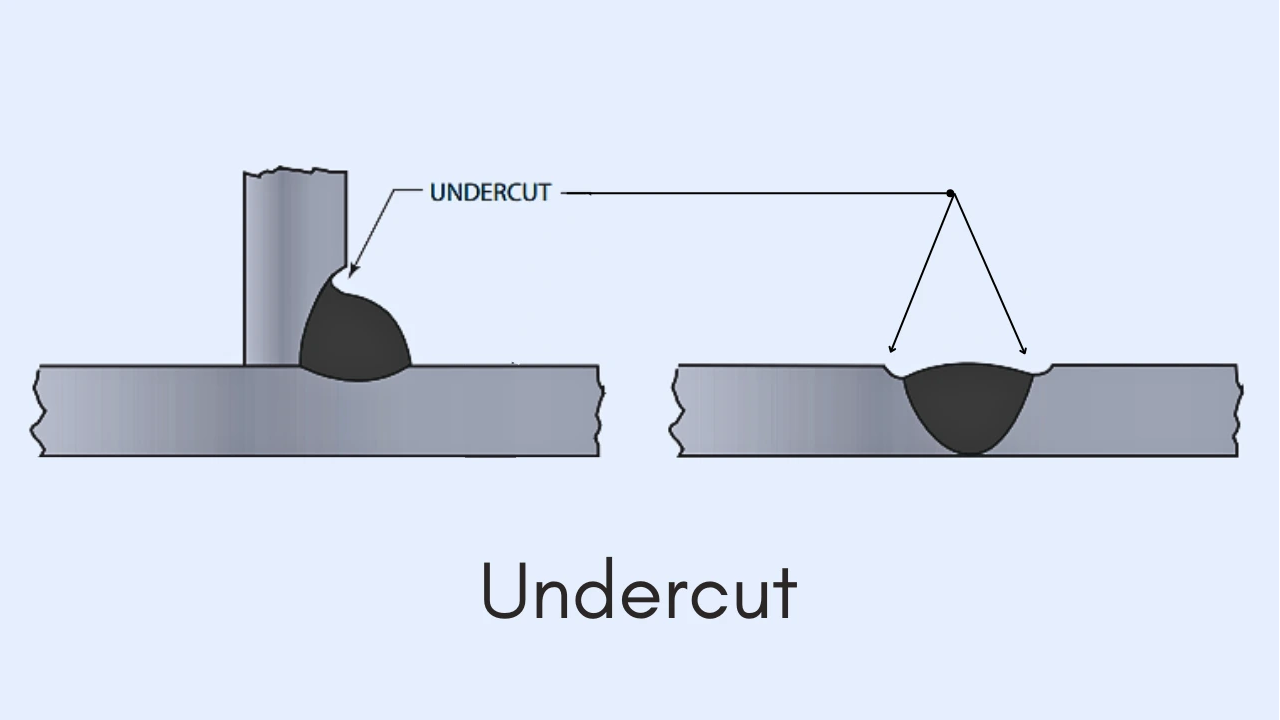

Welding undercut is a defect where the weld reduces the base material's thickness. This can create leak paths in vacuum equipment, undermining its performance.

Let's look at why vacuum equipment is so sensitive to welding flaws and how we can prevent them.

Why Are Vacuum Equipment So "Picky" About Welding?

Vacuum equipment needs extremely tight seals to function correctly. Even small defects can cause significant problems.

Vacuum equipment requires high precision and reliability. Welding defects like an undercut can compromise the vacuum seal and affect performance.

Vacuum Equipment

Vacuum equipment operates under extreme pressure differences. Any weakness in the weld can lead to leaks, which can disrupt the vacuum environment. For example, in vacuum chambers, a tiny undercut can create a path for gas molecules to enter, increasing the pressure and contaminating the process. In high-vacuum systems, even a minimal leak can significantly impact the system's ability to reach the required vacuum level. This is because the rate of gas entering through the leak is much higher than the rate at which the vacuum pump can remove it. As a CNC machining factory specializing in vacuum chambers, I understand how critical it is to eliminate these defects. We focus on precision and quality to ensure our vacuum equipment meets the highest standards.

How Does Undercut Silently Destroy Vacuum Environments?

Undercut acts as a hidden pathway for leaks. It allows gases to seep into the vacuum, disrupting the environment.

Undercut creates a channel that compromises the vacuum seal. This leads to pressure increases and contamination, harming the vacuum environment.

When undercut occurs, it reduces the effective thickness of the material at the weld joint. This weakened area is more susceptible to stress and can crack under pressure. In a vacuum environment, the pressure difference between the inside and outside of the equipment puts stress on the welds. If an undercut is present, it becomes a point of stress concentration, making it more likely for a leak to develop. The leak might start small, but over time, it can grow due to the constant pressure and thermal cycling. This slow degradation can be hard to detect until it causes a major failure. With my experience in machining vacuum chambers, I've seen firsthand how critical it is to prevent these issues. Our team uses advanced welding techniques and rigorous testing to avoid undercuts and ensure the integrity of the vacuum seal.

Semiconductors, Large Scientific Instruments: Who Has "Zero Tolerance" for Undercut?

Industries like semiconductors and scientific instruments demand perfect welds. Even a tiny undercut is unacceptable.

Semiconductor and scientific instrument manufacturers require flawless vacuum environments. Undercut can cause equipment failure and costly downtime.

Semiconductors

In the semiconductor industry, vacuum equipment is used in many processes, such as etching, deposition, and lithography. These processes require extremely clean and stable vacuum conditions to ensure the quality of the microchips. Even a small amount of contamination or pressure fluctuation caused by an undercut-related leak can ruin the entire batch of chips, leading to significant financial losses. Similarly, in large scientific instruments like particle accelerators and fusion reactors, the vacuum requirements are even more stringent. These instruments often operate at ultra-high vacuum levels (below 10⁻⁷ Pa). Undercut in the welding can lead to virtual leaks, which release trapped gases over time. These leaks can interfere with the experiment, making it difficult to obtain accurate results.

Besides Vacuum, Which Other Industries Are Being Undercut "Wreaking Havoc" In?

Undercut isn't just a problem for vacuum applications. It also affects industries like automotive and shipbuilding.

In industries like automotive and shipbuilding, undercutting weakens structures. This can lead to corrosion and reduced lifespan.

Automotive Parts

In the automotive industry, welding is used to join various parts of the car's chassis and body. Undercut in these welds can reduce the structural integrity of the vehicle, making it more vulnerable in accidents. Moreover, the automotive industry uses many different types of metals. Undercut can create crevices where moisture and salts can accumulate, leading to corrosion. This can weaken the weld over time, potentially leading to structural failure. The shipbuilding industry faces similar challenges. Ships are constantly exposed to seawater, which is highly corrosive. Undercut in the welds of the ship's hull can accelerate corrosion, shortening the lifespan of the vessel. This is especially important for ships that operate in harsh environments, such as arctic regions or deep seas.

How Do We "Snipe" Undercuts and Ensure Perfect Welding?

We use precise control and special techniques to prevent undercut. This ensures high-quality, leak-free welds.

By carefully managing welding parameters and using advanced processes, we eliminate undercut. This results in durable, reliable welds.

As a CNC machining factory, we have a team of welding experts with 30 years of experience. We have developed ultra-low leak rate welding technology and strict non-destructive testing (NDT) methods. For example, radiographic testing uses X-rays to detect internal defects like undercut. Ultrasonic testing uses sound waves to find surface and subsurface flaws. We precisely control welding parameters like voltage, current, and travel speed to minimize undercut. We also optimize welding sequences to reduce heat input and distortion. For materials like titanium alloys and aluminum alloys, we use special welding processes such as pulsed TIG welding. Pulsed TIG welding precisely controls the heat input, minimizing the risk of undercut. Our goal is to provide solutions with a post-welding vacuum of up to 10⁻⁵ ~ 10⁻⁷ Pa and a leak rate of less than 10⁻¹² Pa·m³/s.

Conclusion

Welding undercut can be a fatal flaw, especially in vacuum applications. By using advanced techniques and strict quality control, we ensure perfect welding and prevent costly failures.