What is Welding Automation?

Welding automation is the application of automated technology, program-controlled equipment, and advanced software to execute welding operations with negligible human intervention. Welding automation encompasses the complete process of welding (part positioning and loading, ending with the weld), ensuring accuracy, speed, and reproducibility in complex processes. With automated processes replacing the manual approach, industries gain improved productivity, weld quality consistency, and reduced operation costs, primarily in the areas of mass production. Flexible systems, such as robotic welding arms, automated welding cells, and dedicated equipment, are optimized to meet specific manufacturing needs rather than utilizing generic setups. The use of welding automation extends beyond efficiency to include safety and scalability while maintaining flexibility in an extensive variety of industrial processes.

Classifications of Welding Automation Systems:

By the mechanization level

- Machine welding

Machine welding is described as mechanized welding using equipment that operates continuously under an operator's supervision. It is often achieved by moving the work in relation to a stationary welding head or by moving a welding head that is mechanically moved in relation to a stationary workpiece. For the operation to be controlled, the human worker must constantly monitor and engage with the machinery.

- Automatic welding

Automatic welding is the term used to describe equipment that can carry out an activity without human operator control. Typically, a human worker is present to supervise the procedure and identify deviations from standard operating parameters. The ability of a weld cycle controller to control the arc movement and workpiece location without constant human supervision sets automated welding apart from machine welding. For automatic welding, the work must be positioned in relation to the welding head using a welding fixture and/or positioner. Higher levels of precision and uniformity in the component parts employed in the weldment are also necessary. Because of these factors, automated welding is only appropriate for high-volume manufacturing.

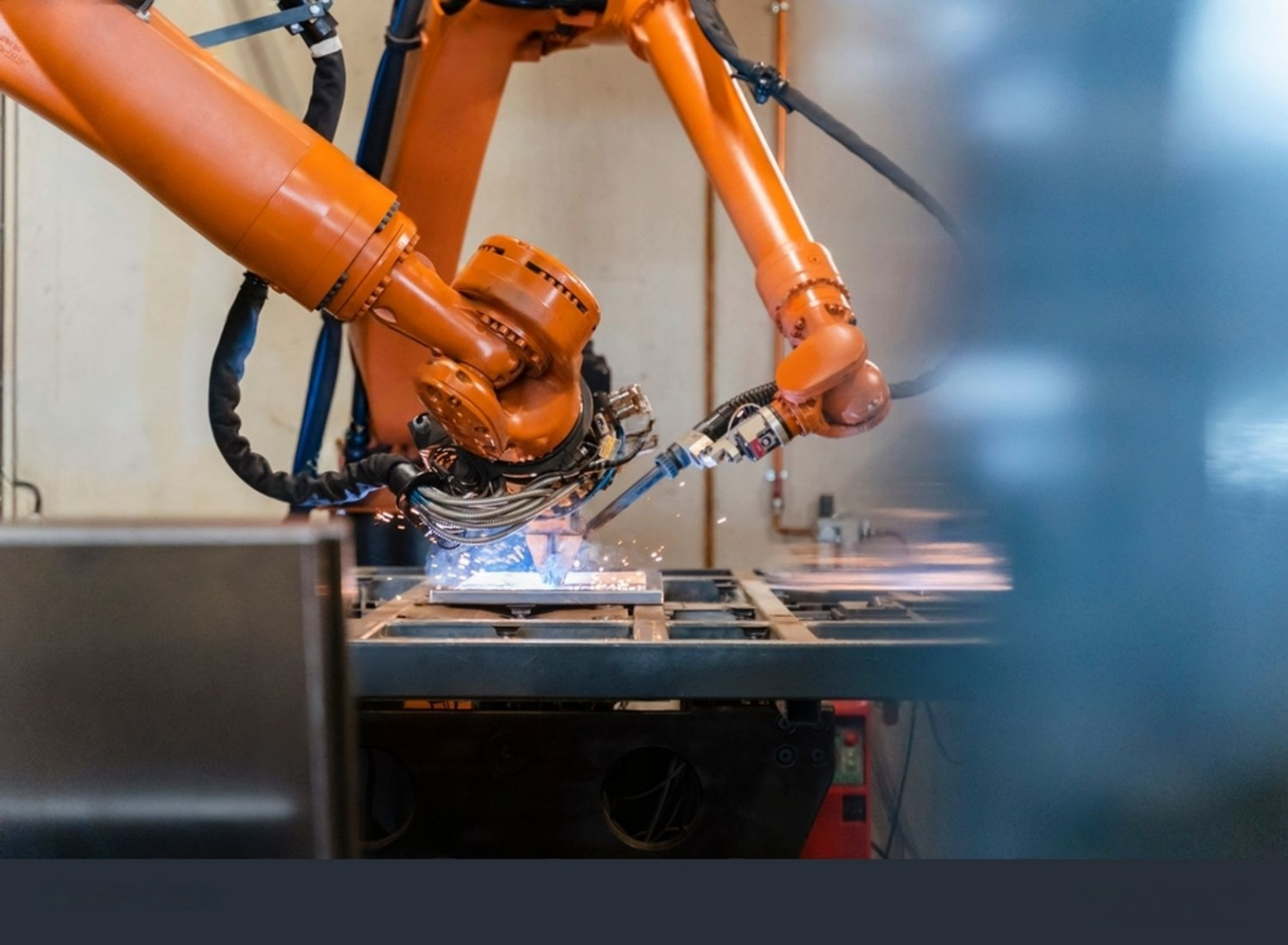

- Robotic welding

Robotic welding uses a programmed manipulator or industrial robot to autonomously control the welding head's movement in relation to the job.

A manipulator

Due to the robot arm's adaptable reach and its ability to be reprogrammed for different part configurations, this type of automation can be justified for relatively small production numbers. As the robot welds, a human fitter loads and unloads components from two welding fixtures in a standard robotic arc welding cell. Industrial robots are employed in automobile assembly factories to perform resistance welding on automobile bodywork in addition to arc welding.

By Control Flexibility

- Fixed automation

Fixed automation is large-volume production with a sole concern of manufacturing identical parts efficiently. It is optimized for consistency, as this type of fully automatic welding system best fits mass-scale production. Though its initial capital cost and maintenance are high, its purpose-built structure offers the best speed and output reliability, making it indispensable to standardized repetitive manufacturing lines.

- Programmable automation

Best for moderate production levels, programmable automation blends semi-automatic welding with flexible systems capable of responding to part variation. Cost-effective but efficient, the solution leverages reprogrammable machinery for an easy transition between product designs without overhauls, thus providing flexibility with minimal inefficiencies. It meets diversification needs on one end and provides continuity in product quality on the other end (most applicable in industries requiring moderate batch sizes and switchovers between custom or evolving product lines).

- Flexible automation

Flexible automation optimizes low-production-volume welding manufacturing by allowing rapid changeovers from one operation to another. This semi-automatic process uses versatile systems to economically make diversified parts. Compared to fixed installations, hardware is cost-effective and easily translatable to a variety of lines of products, leading to fewer downtime hours. Ideal for fluctuating production needs, it offers manual control blended with automated precision, achieving efficiency without compromising flexibility.

- Adaptive control systems

Adaptive control systems complete welding automation by using real-time feedback to dynamically control parameters and react to change, for instance, in variations of materials or environmental conditions. Adaptive systems guarantee weld consistency and quality, particularly for difficult geometries or obstinate materials. Ongoing monitoring of processes and response to changes provides these systems with confidence in precision and reliability with reduced defects and improved efficiency, thus making them inevitable in use for high-level industries that require reproducible outputs.

Core Technologies Enabling Welding Automation

Welding robots & manipulators

Industrial robot arms are the cornerstone of modern welding automation, with multiple axes of motion to make complex weld trails. Articulated robot arms work best in intricate applications, delivering high-accuracy MIG, TIG, or laser welds in hard-to-reach positions (perfect for automotive, aerospace, and shipbuilding applications).

welding robotic arm

Facilitating these systems, positioners and manipulators optimize workflow by precisely rotating or tilting workpieces for improved weld accessibility and consistency. Robotic welding systems and manipulators in combination maximize bulk production, minimize human error, and maximize repeatability. This integration of state-of-the-art robotics and workpiece orientation equipment drives efficiency in challenging manufacturing environments without compromising rigorous quality controls.

Sensors & vision systems

Advanced vision systems and sensors are essential to precision in robot welding. Real-time feedback is utilized by weld-tracking sensors to monitor joint positions and robotically compensate to maintain them aligned (even when the geometry of the joint changes). Vision systems using high-resolution cameras or proprietary optics inspect weld beads in-process and post-process and detect such defects as cracks, porosity, or undercut. This dual ability ensures consistent weld quality, minimizes errors, and reduces rework, enabling producers to deliver high levels of quality while optimizing production efficiency.

Controllers & software

Advanced welding automation relies on high-performance controllers and software to offer accuracy and productivity. Weld-cycle controllers and Programmable Logic Controllers (PLCs) drive robotic systems, guiding the sequence of operations, speed, and parameters for advanced tasks as well as reacting to new production requirements. Supporting these are simulation technologies that enable pre-production process optimization by simulating weld conditions, predicting defects, and parameter optimization virtually. This reduces trial-and-error physical application, accelerates setup, and enhances quality (streamlining processes on automated welding zones).

Benefits of Welding Automation

- Improved productivity

Automated welding improves productivity by faster completion of tasks, faster than doing them manually, for higher output. Automated operations improve throughput, resulting in reduced cycle time and on-time delivery, which improves global competitiveness. High-quality welds due to reproducibility reduce material wastage from defects occurring and the cost to produce. Furthermore, high precision in welding promotes sustainable manufacturing by allowing companies to quickly react to market demand while maximizing resource efficiencies and effective processes.

- Improved quality & consistency

Automated welding improves weld quality through its precision-based reliability and repeatability. Advanced electronic controllers for welding can store thousands of precision parameters (temperature, etc.) to allow the reproducibility of variables at a large volume of production. Sensors, vision, and other systems can monitor the welding operation in real time as well as immediately identify any deviations so that corrections can be made while doing the original operation. This reduces the possibility of defects, lowers rework, and increases the certainty of the product. Automated welding delivers reproducible welds of the same quality because it prevents human variances while incorporating safety and productivity measures, making it critical in applications that require high quality and high repeatability.

- Improved safety

Automation of welding operations increases safety by removing the requirement for workers' exposure to dangerous environments. As automated operations are handled by robots, they can work in tight spaces, and they also execute work in high temperatures, dealing with toxic fumes, reducing the risk of respiratory risk, burns, and injury. Similarly, reducing manual handling, eliminate injury or musculoskeletal disorders. This exciting technology presents efficient solutions that provide precision and performance while protecting workers from hazardous environments.

- Cost savings

Automation of welding operations can decrease labor costs, which comprise an estimated 70% of the cost of welded parts. A robotic device can stand in the place of 2-4 welders, providing consistent welding production. However, reduced rework from precision welding realizes greater savings as a result of fewer defects. The long-term efficiencies and resource savings will create a return on investment that warrants long-term consideration of the automation for sustainable and quality production practices.

Industry Applications

Welding automation has disrupted industries by greatly improving precision, efficiency, and safety. Below are the major industries finding newly created advantages with welding automation.

- Manufacturing

In manufacturing, robotic welding systems were pioneered to automate processes that involve welding numerous parts, such as chassis, frames, and body panels, at high volume. Consistent quality comes from processes like MIG and TIG welding, which often produce the same part over and over again, at a high production rate, with low labor costs and high precision (eliminating operator errors). Advanced robotic welding systems are now able to manipulate the workpieces even when they get heavier, and AI welding is increasing deflections, pulsed bead placements, and adjustable parameters for all sorts of materials and processes, allowing for greater production rates.

- Automotive

The automotive industry relies on resistance spot welding for processes like welding body panels or exhaust systems. Robotic systems ensure precision, speed, and consistency when welding the car frames and associated components compared to fixtures alone or operators. Pulsed MIG welding is now used for aluminum-based components used in high-speed vehicles, which provides structural integrity at a lighter weight. Automation not only speeds up automotive production by 5-10% but also prevents problem costs with defects by upwards of 20%, with safety subject to stringent standards.

- Aerospace and Defense

The aerospace industry requires impeccable welds on fuselage sections, engine components, and landing gear. Precision can be attained through orbital TIG welding or electron beam welding, particularly when making welded joints in hard-to-reach places. Friction stir welding can also be used to join lightweight aluminum component types without the need for filler. Automated welding systems can be adjusted for a specific output heat, such as in aluminum alloys subject to aerospace specifications.

- Shipbuilding & Marine

Shipyards are using submerged arc welding (SAW) on thicker-grade steel hulls and orbital gas tungsten arc welding (GTAW) systems to make reliable joints in pipelines, making up confined piping networks. Robot systems are making joints in tight, confined spaces to provide leak-free and consistent processes in fuel and ballast systems. With the amount of skilled labor struggling to keep up with demand and hazardous manual welding taking place in confined environments, automating shipbuilding to provide consistent quality and help the industry comply with safety standards is the new norm.

Challenges & Considerations

Though welding automation offers game-changing advantages, including higher output levels and repeatable weld quality, implementing welding automation does present challenges to assess in several categories, including technical, fiscal and operational factors to contend with.

- Technical issues

Welding automation must have measured control around dynamic variables, such as material characteristics, fit-up of the joints and accuracy of the fixture. Even small variations in the alignment of parts, thickness of the material, or degree of thermal expansion can lead to inconsistent welds. An advanced automation system will require adaptive sensors and raw feedback capable of changing variables such as the heat input or the travel speed of the torch throughout the entire weld to ensure a more repeatable process. Technology advancements will not change the critical importance of fixture design since misalignment greater than a few sub-millimeters can generate excessive defects. High-precision tooling and calibration will be essential.

- Economics

The high initial capital costs of robotic arms, controllers and dedicated software can be overwhelming. While automation can eliminate labor and material waste over time, a full ROI will necessitate some analysis. Ultimately, the volume of expected production will determine a business's cost to automate. For example, the capital inputs may not reflect well for lower production volumes or highly customized jobs. Aiming the automation towards high-throughput repetitive processes is a good first step to support allowable savings from rework.

- Multi-Skilled Workforce

The move toward welding automation provides a tremendous advantage that may result in less skilled labor being required; however, it is important to observe a shift in skill requirements. More strongly, configurations from manual welding to automated systems require additional skill in technician roles, including programming robotic operations and experience with PLCs & CAM software, while also maintaining the systems and knowledge of working on systems qualifications at certain points in the production process. The multi-skilled trained worker shortage is an additional barrier to implementation, which will involve forming partnerships with technical colleges and training programs, or forecasting levels of training from being upskilled within the organization.

- Integration & Flexibility

In situations where welding automation is introduced into older systems (legacy) or into older machines beyond obsolescence, there can be a lack of compatible machinery or software. Generally, this requires first being upgraded to newer versions, or integrating software to perform in a middleware approach, or expecting the use of several phases to access the appropriate automation. Furthermore, conventional automation is severely under-performing in low-volume production environments where there is still a high mix of varying types of products produced or operated. A hybrid approach, using cobots or modular cells, is meant to allow for flexibility and custom jobs at a level while still providing an acceptable throughput for standardized designs.