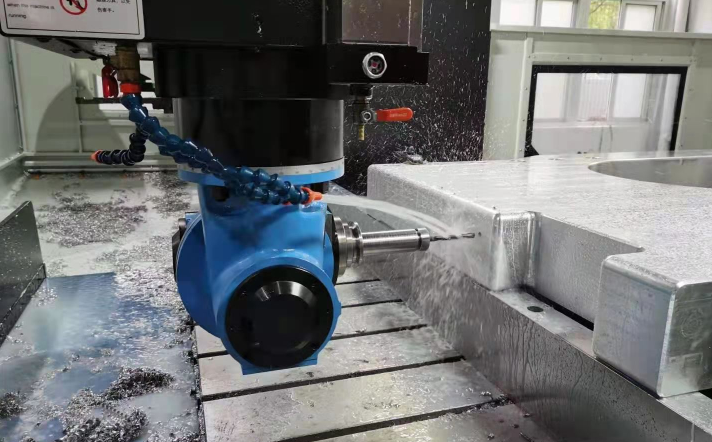

The side milling head is a machine tool accessory. After installation, the tool rotation center line can be processed at an angle with the spindle center line. Without changing the structure of the machine tool, the processing range can be increased, thereby reducing the repeated clamping of the workpiece, and greatly improving the processing accuracy and processing efficiency.

Practical application of side milling

1. Large workpieces are not easy to fix and are used for simple processing;

2. Precise workpieces are fixed at one time and require multi-faceted processing;

3. Relative to the datum plane, it can be processed at any angle;

4. Keep a profile milling pin with a special angle during processing, such as ball end milling;

5. The drilled middle hole or other tools cannot drill the small holes in the hole;

6. Machining oblique grooves, oblique holes, etc., such as engine, engine, etc. in the box body.

The multifunctional milling head automatically changes the tool, and the tool changer is installed on the back side of the gantry machining center, including a tool magazine and a tool change mechanism. The tool magazine is a chain tool magazine, and the tool holder of the chain tool magazine is equipped with two different specifications of tools. set;

The tool changer includes a tool changer arm and a moving device. The moving device of the tool changer arm is installed on the inside of the tool magazine. A pair of claws and a pair of claws are provided on the upper part.

Through the perfect coordination of the four claws and the tool magazine, the functional milling machines with different tool holder types are automatically replaced, and the milling machines with different tool holder types are configured to reduce the limitation of the function of the milling machine.