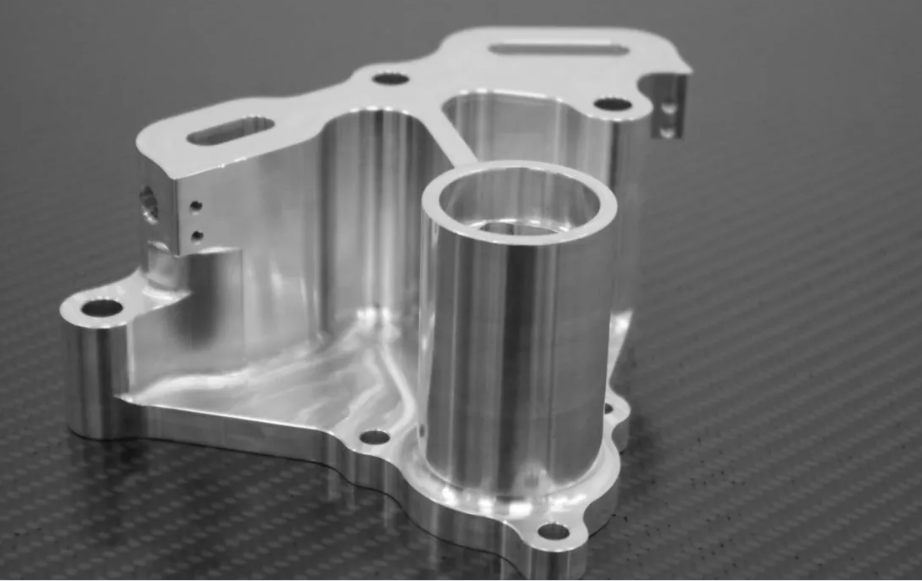

From the aerospace industry to home appliances machine parts are everywhere and you can easily understand why they are essential in the modern world. The main benefit of the machine parts is that they can easily fabricate into the desired system without any surface finishing technique, and machining services show excellent results in precision and accuracy.

For that reason most manufacturers prefer to use CNC machining services, a perfect 3D model designed on engineering software and precise calculations are required to meet up the required standards. A minor error in design means that the part does not function properly, so accuracy and precision are critical in machining. Most machinists prefer to ask about product samples for precise results and accurate parts manufacturing. This is a good practice in this domain because a machinist can easily do reverse engineering on a specific project and create a 3D model based on the dimensions of the sample product. The accuracy and lead time of the product are improved by using this technique.

In this article, I will discuss briefly why it is significant to provide a sample part to your machining vendor. How reverse engineering works, and what benefits it brings to machining.

Benefits of providing sample parts to machine vendors:

The operation of machining services begins with the specifics of the product's usage, application, and working time. Concerning that, a suitable material is chosen based on the working conditions. It is the most important aspect because it determines the durability and effectiveness of the product. Engineers are focused on creating an accurate and precise product design using 3D engineering CAD software after choosing a material. Before sending it to the machinist, some wear and tear analyses are performed on it. The machinist then manufactures the product according to the dimensions provided.

Providing a sample part for your machining services insured Precision machining, As custom designs, may lead to some tolerance issues. So machinists prefer to go with sample products to lead time and manufacturing issues.

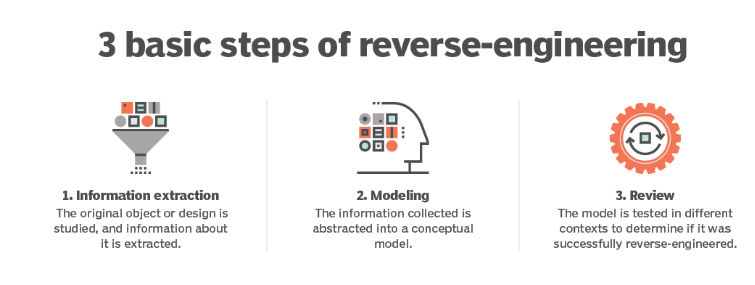

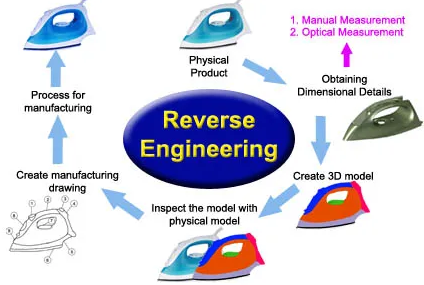

How Reverse Engineering works?

Reverse engineering is the process through which parts are reopened to extract designs through them. it is also known as back engineering, the parts especially related to aerospace, automobiles computer chips, and other heavy mechanical and electrical units open to extract design details through them.

Most industries follow this technique to meet up the precision and accuracy requirements, your provided sample product is analyzed by analyzing it through laser scanners, 3D scanners, CMMs, and industrial commutated tomography under highly experienced engineers and designers. These softwares automatically extract all the necessary information and feed it to the database for further processing. the extracted information is used to make a 3D model from the extracted dimensions to meet up the target of producing an exact accurate part.

Having a clear view of the part, and how it works and interacts with the machinery, gives a detailed understanding to produce precise and versatile machine parts.

Failure analysis and Product improvement:

Reverse engineering plays a valuable role in failure analysis and product improvement. When the machine fails you need to figure out its fault by opening it and studying the detail of its designs, this practice gives access to its complexities. secondly, if a product fails, or is damaged during work you can easily know which part needs to be changed, the engineers can do the design alteration on a 3D model design that was prepared by reverse engineering. For example, if some joint of the product need to be welded or reinforced or some new material has to be implemented it can easily be measured, redesigned, or replaced by stronger metals.

Only reverse engineering will work If your machine is quite old and the desired part's blueprints are not readily available, the only option is to provide a sample part; through reverse engineering, we can create a 3D design and build a database to save the legacy of their past products.

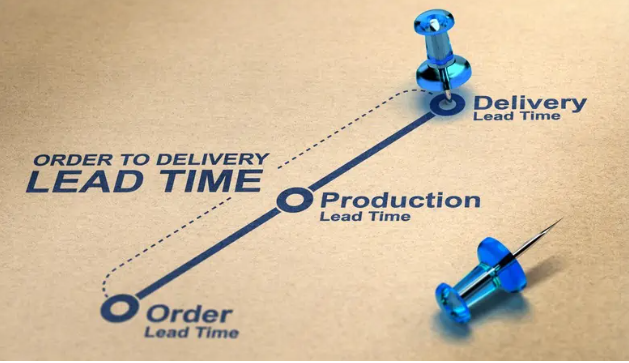

Lead time Reduction:

Lead time is the main concern of both the manufacturers and the clients, engineers always do their R&D on reducing the lead time of the products, and for that concern, they are considering optimizing materials, design, and complexities. For that reason, it is always advised to provide a sample product so that, the working time can be reduced.

Furthermore the deep analysis of the products, surely reveals all the weak loopholes of the part, and engineers are quite clear about the structure, requirements, and product improvements. which definitely reduces the overall lead time of the product. If the sample part is not given and one has to design it from scratch, it needs a lot of research and analysis, a 3-d model is prepared, checked, and analyzed after prototyping, it is ready to be used.

Choosing the right machine Shop:

Reverse engineering is not an easy job, a high level of skill set and advanced machinery are required to achieve the required type of Precision and accuracy. So, before hiring any machine shop vendor, one should conduct thorough research to ensure that they have the necessary capabilities, training, and expertise in the field. For example, if your product is required to be machined on 5-axis machinery then how can a machine shop which is not equipped with modern and advanced machinery can fulfill your job. Furthermore, the company should have a good working profile and rich market experience, as the statistics show that your selected firm has capable engineers and designers, which have rich machining and manufacturing experience, and they understand the design complexities and are ready to do reverse engineering projects.