What Is CNC Machining?

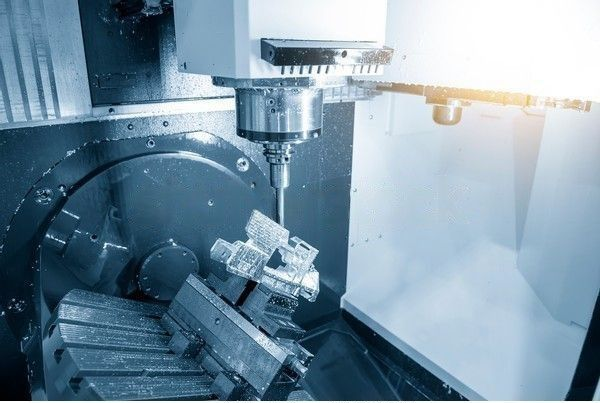

CNC machining is a type of subtractive manufacturing, which means that throughout the production process, material is removed rather than added. This indicates that CNC machining begins with a block of material (referred to as a blank) and employs swiftly moving cutters to quickly remove material and make the completed product. This effectively makes it the reverse of additive manufacturing, such as 3D printing, which builds three-dimensional items layer by layer using materials put into 3D printers.

In CNC machining, industrial equipment and tools are moved according to pre-programmed computer software. The method may be used to operate a variety of complicated machinery, including mills, CNC routers, lathes, and grinders. Three-dimensional cutting jobs may be completed with CNC machining with just one set of instructions

The manual control method has its limits, which the CNC process overcomes. With manual control, live operators are required to initiate and direct the commands of milling equipment using levers, buttons, and wheels. A CNC system may appear like a typical collection of computer parts to someone looking on, but the software and consoles used in CNC machining set it apart from all other types of computation.

CNC machining system Parts

A CNC system is composed, at its core, of six functionally integrated parts that work together in synchrony. The primary components of the CNC system are as follows:

- input gadgets

- Machine control unit (MCU)

- Machine tool.

- Driving mechanism

- feedback mechanism

- Display unit.

Input Gadgets

Since a CNC system is managed and controlled by a specialized system, there needs to be a reliable method of coordinating the pre-programmed data with the specified system. There are three commonly used input devices: punch tape reader, magnetic tape reader, and computer through RS-232-C connection.

Machine control unit (MCU)

The core of the CNC machine is referred to as the machine control unit. Besides carrying out all of the CNC machine's control operations, the MCU also handles a number of other jobs, including:

- It decodes the encoded instructions and reads them.

- The coded instruction is decoded by the machine control unit.

- To create motion commands, this axis employs interpolation (linear, circular, and helical).

- The amplifier circuit receives the axis motion command from the machine control unit and drives the axis mechanism.

- It incorporates auxiliary control features like tool switching and coolant or spindle on/off.

Machine tool

In order to manage position and speed, a CNC machine tool is always equipped with a sliding table. The machine's spindle and table are both controlled by the Z-axis, while the X and Y axes move the table.

Driving mechanism

An amplifier circuit, drive motors, and ball lead screws are all parts of a CNC machine's driving system. The amplifier circuits are fed by the MCU with signals for each axis' location and speed. To activate the drive motors, the control signals are augmented (increased). In order to position the machine table, the ball lead screw is rotated by the actuated drive motors.

Feedback mechanism

Sensory transducers are a part of the feedback system. Alternatively, it is known as a measurement system. It is composed of position and speed transducers that constantly track the whereabouts and speed of the cutting tool used at any one time.

In order to create control signals that correct position and speed mistakes, the MCU receives signals from transducers and compares them to reference signals and feedback signals.

Display unit

The CNC machine's programming, instructions, and other essential data are shown on the monitor.

Principle of CNC operation.

It has two distinct controllers, including a CNC controller that performs functions like program decoding, interpolation, diagnostic machine actuation, etc. Another is the programmable logic controller (PLC), which controls things like the functioning of turrets, spindles, and coolants.

Slides are moved using servomotors with their own feed drives (AC or DC), ball screws, or nut drives. The motors of the feed drive are controlled by the controller. Either the table or the motor, which measures the sliding position, have the appropriate transducers installed.

In order to guarantee precise placement, the location is also tracked and verified using feedback transducers. Stepped motors, either AC or DC, are provided for the spindle. The spindle motor's speed may be changed with a proper control. The shaft is attached to an appropriate feedback mechanism that keeps an eye on the speed. The CNC machine operates in this way.

How Do CNC Machines Work

The steps below make up the fundamental CNC machining process:

- the CAD model creation.

- CNC program creation from a CAD file.

- setting up the CNC machine

- completing the machining process.

CAD model creation

The 2D vector or 3D solid component CAD design is produced either internally or through a CAD/CAM design service firm as the first step in the CNC manufacturing process. Designers and custom cnc machining companies can create a model or depiction of their parts and products using computer-aided design (CAD) software, together with the technical requirements for making the part or product, such as measurements and geometry.

The capabilities (or limitations) of the CNC machine and tooling limit the designs that can be used to produce a given set of parts. For instance, because curved corner sections are produced by the tooling used in the majority of CNC machines, the component geometries that may be produced using this method are constrained.

The limitations on design possibilities are further increased by the characteristics of the material being machined, the design of the tools, and the work holding capabilities of the machine, such as the minimum and maximum part sizes, and the inclusion and complexity of internal cavities and features.

A CNC-compatible file format, such as STEP or IGES, is exported by the designer once the CAD design is finished.

CAD file creation

CNC program creation from a CAD file

A program, often computer-aided manufacturing (CAM) software, processes the structured CAD design file to extract the component geometry and output the digital programming code that will operate the CNC machine and manipulate the tooling to make the custom-designed part.

G-code and M-code were two of the programming languages used by CNC machines. The most well-known CNC programming language, general or geometric code (also known as G-code), directs how the machine tools move over the workpiece, including when to switch on or off, how quickly to get there, and what pathways to take.

The M-code, or other function code, manages the machine's auxiliary operations, such as automating the machine cover's removal and replacement at the start and conclusion of production, respectively. The CNC machine operator loads the resulting CNC program once it has been created.

Machine Setup

The operator must set up the CNC machine for operation before running the CNC software. In order to make these preparations, the workpiece must be fastened into the machine, onto its spindles, into a machine vise, or into a similar workholding device. Additionally, the necessary tools, such as drill bits and end mills, must be attached to the correct machine parts. The operator can start the CNC program once the machine has been properly configured.

Completing the machining process

The CNC program serves as instructions for the CNC machine; it sends machine commands specifying the actions and motions of the tooling to the machine's inbuilt computer, which operates and manipulates the tooling. When the program is started, the CNC machine is prompted to start the CNC machining process. The program then directs the machine as it carries out the required machine operations to create a component or product that is specifically designed.

If a cnc machined parts manufacturer invests in purchasing and maintaining its own CNC equipment, CNC machining operations can be carried out in-house, or they can be contracted out to specialized CNC milling services providers.

G-Code vs M-Code

It's a prevalent misperception that all machining operations require G-code. This is untrue, though, as the code may be divided into the two codes.

A language used to instruct a machine on how to move is referred to as G-code. It is essentially the geometric code. Cutting head motion and speed are controlled via G-code.

An industrial computer known as a machine controller is provided the instructions. This then determines how the motors should operate. The path that will be taken is of course decided by the motors.

On the other side, the M-code provides all the information that the G-code omits. It is referred to as machine code or miscellaneous code for this reason. It is referred to as machine code or miscellaneous code for this reason.

The instructions in M-code include topics like changing tools, using coolant, stopping programs, and more. Therefore, while not identical, both are equally vital.

Types of CNC Machines

The following machines are the most often used ones in CNC systems:

CNC Mills

One of the most popular forms of CNC machining, recognized for its high precision and tolerances, is CNC milling. After materials are loaded into CNC machines, the computer will direct the drilling and cutting tools as they perform their magic. CNC machines are equipped with built-in tools for drilling and cutting.5 axis CNC milling is frequently used for more complicated geometries and is done in a single operation, whereas 3 axis CNC milling is often the better choice for making simpler parts.

5 axis cnc mill

CNC lathe machines

When using a lathe, indexable tools are used to cut parts in a circular motion. The cuts made by lathes with the help of CNC technology are precise and swift. In contrast to manually operated versions of the equipment, CNC lathes can generate complicated designs. CNC-driven mills and lathes have many of the same control features. The same G-code or proprietary code that is used to control CNC mills may also be used to control lathes. Most CNC lathes have two axis namely the X and Z axis.

CNC Lathe machine

CNC plasma-cutting machines

Plasma-cutting CNC machines are used to cut materials and are comparable to CNC milling machines in that regard. However, they are different from their milling counterparts in that they use a plasma torch to do this action.

CNC laser-cutting machines

The purpose of laser-cutting CNC machines is to utilize a laser rather than a plasma torch to cut through resistant materials. However, they are not as powerful as plasma torches, while having a better level of cutting precision.

Electric Discharge CNC

Is a particular kind of CNC machine that cuts materials into the required shape using electric sparks. The materials are placed between the top and bottom of the electrode, and the computer then determines how much electrical discharge the electrodes create.

Wire EDM

Water Jet Cutters

Water jets are tools used in CNC machining to cut tough materials like metal and granite using high-pressure water applications. Sand or another potent abrasive material may occasionally be added to the water. This procedure is frequently used by businesses to shape industrial machine components.

When a material can't withstand the heat-intensive procedures used by other CNC machines, water jets are used as a cooler alternative.

Benefits of CNC machining

When compared to traditional machining, the CNC method provides the following benefits:

- Increased machining precision.

- The consistency of produced parts.

- It's possible to manufacture complex geometries.

- High productivity since setup and changeover times are shortened.

- Reasonably priced production for huge numbers.

- Lower labor expenses.

- Automation in manufacturing is conceivable.

Contact CNC MILLING CHINA if you want the best in CNC manufacturing. As a business, we're committed to giving each customer we work with outstanding value. Because of our dedication, we are able to create parts and components that are custom-made and created to meet the requirements of your business. See what we can accomplish for you by looking over our CNC precise machine services right now. Please get in touch with Kunshan Baichuan if you have any queries.