What is Material Testing & Why is It Important for CNC Machining

Imagine making parts, only to find they break easily. What if a car part fails, causing an accident? Material testing helps avoid these disasters. Material

Imagine making parts, only to find they break easily. What if a car part fails, causing an accident? Material testing helps avoid these disasters. Material

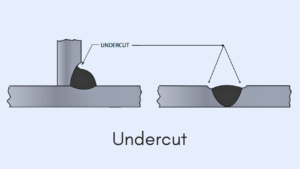

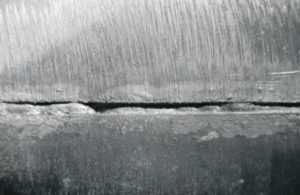

Welding undercut is a serious defect that can compromise the structural integrity of your high vacuum equipment. By understanding the causes, implementing proper prevention techniques, and using reliable detection methods, you can minimize the risk of undercut and ensure the long-term performance of your critical components.

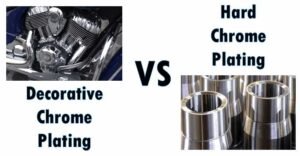

Chrome plating offers exceptional value for CNC-machined parts facing demanding conditions. Whether you need maximum durability, wear resistance, or aesthetic appeal, modern chrome processes can deliver the performance your application demands while addressing environmental concerns.

There is a growing movement towards seeking cleaner and safer methods in line with escalating international regulations. It is possible to safeguard the Earth through collaboration with partners who adopt eco-responsible practices. Responsibly, chrome plating’s future lies in ensuring effective approaches to sustainable decisions, and it starts with you.

Welding can change the shape and size of metal parts. This is because of the heat involved. Are these changes predictable? Yes, welding deformation can

Imagine your equipment failing because of a tiny welding error. Welding undercut can be a critical issue, especially in vacuum applications. Welding undercut is a

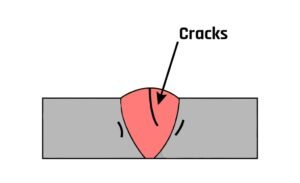

Vacuum chambers must be airtight. But what happens when welding introduces cracks? This can be a costly problem. Welding cracks appear because of stress and

Welding automation is the application of automated technology, program-controlled equipment, and advanced software to execute welding operations with negligible human intervention.

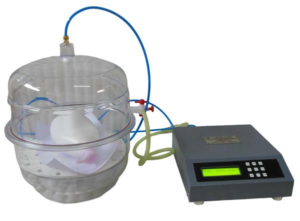

Even the tiniest leak in packaging can lead to massive issues, including financial loss, safety issues, or a loss of business reputation. But don’t worry!

Lack of fusion happens when the weld metal doesn’t properly bond to the base metal. This can create weak spots in your vacuum chamber, leading to leaks and performance issues.

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215312, Jiangsu, P.R. China

Email: sales92@partstailor.com

Phone: +86-18551199566

Kunshan Baichuan Precision Components Co., Ltd

Address: Building 1, No.525 Maoxu Road, Kunshan 215312, Jiangsu, P.R. China

Email: sales92@partstailor.com

Phone: +86-18551199566

Subscribe to receive our latest news and innovations directly in your inbox.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.

We will contact you within 1 working day, please pay attention to the email with the suffix “@partstailor.com”.