Have you ever pondered the consequences of even the smallest leak in a vacuum chamber? How do sectors that depend on these chambers—from semiconductor manufacturing to space exploration—ensure their systems are airtight? Leak testing, an important step in the vacuum chamber post-processing process, holds the key to the solution. Avoiding costly failures, preserving system integrity, and preventing contamination are more important goals than merely patching flaws.

This blog explores the intriguing realm of post-processing leak testing and explains why it's an essential part of vacuum chamber quality control. We'll explain how every technique, from advanced methods like helium mass spectrometry to traditional bubble tests, assures the complete dependability of the vacuum chamber. Are you ready to learn the methods and science underlying leak testing? Explore and learn how this crucial procedure safeguards innovative ideas and maintains industry progress.

2. Types of Leaks in Vacuum Chambers

Vacuum chamber leaks may affect the integrity, dependability, and performance of procedures or experiments that depend on a steady vacuum environment. The primary kinds of leaks that are frequently seen in vacuum chambers are as follows:

1. Real Leaks:

There is a real leak when gas from the outside environment can enter the vacuum chamber. These paths frequently arise from the following physical flaws or defects:

- Welds or joints that are poorly sealed

- The chamber wall has holes or cracks in it.

- Gaskets that are damaged or poorly fitted

2. Virtual Leaks

Virtual leaks originate from trapped gas pockets within the chamber or in assembly sections rather than from direct exterior channels. The gradual gas release into the chamber by these pockets makes it challenging to establish and sustain a vacuum.

Typical Reasons:

- Spaces between assembly components

- Contaminants or unclean surfaces that were present during assembly

- Internal cavities or bolt holes are examples of structural components that trap gas.

3. Permeation Leaks

Permeation leaks occur when gas molecules gradually permeate the materials of the gaskets, seals, or walls of the vacuum chamber. Even in the absence of obvious flaws, ambient gases can enter the chamber thanks to this diffusion.

Variables Impacting Permeation:

- Properties of the material (rubber gaskets, for example, have higher permeability)

- Chamber wall and seal thickness

- Type of gas and pressure difference between the chamber's interior and exterior

4. Weld Leaks

Tiny leaks in the chamber at or close to welded joints. Inappropriate welding methods, porous welds, or incompatible materials can all cause this leak.

Reasons for this Leak

- Mismatched materials at the weld joint,

- poor welding techniques,

- contamination during the welding process.

5. Thermal Leaks

Leaks that arise from the thermal expansion or contraction of materials, can lead to the formation of cracks at high or low temperatures or the loss of seal integrity. It is also known as reversible leaks.

Reasons of Leak

- Frequent temperature changes

- Exposure to extremely high or low temperatures might put stress on seals or chamber materials.

6. Mechanical Leaks

These are leaks that happen because of mechanical movement or stress on the chamber; they usually happen around bolts, flanges, or seals.

Sources:

- Mechanical connections that are out of alignment,

- Bolts that are overtightened or loosened,

- Mounting hardware tension.

7. Stress-Corrosion Cracking Leaks

Tensile stress and exposure to a corrosive environment combine to generate stress-corrosion cracking, which results in leaks.

Sources:

- Particular metal alloys,

- particularly stainless steels, are stressed by particular gasses or chemicals.

3. Leak Detection Standards

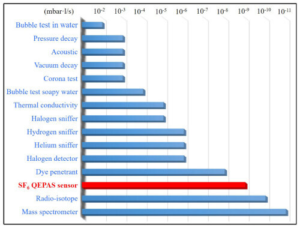

In vacuum systems, leak detection is essential to preserving process performance and integrity. In the field, several standards and units are employed to guarantee accurate and consistent leak rate measurements. Here are some leak detection standards:

ISO 3567.

The procedures for determining the leak rate of vacuum systems and their components are clarified in this international standard. It offers recommendations for evaluation and testing protocols.

Application:

Frequently utilized in semiconductor manufacturing and other fields where high vacuum integrity is necessary.

ASTM E-498

The methods for testing vacuum systems and components for leaks using helium as a tracer gas are clarified in this standard. It explains how leaks can be found, including how mass spectrometers can be used. Methods such as bubble emission, halogen diode, and helium mass spectrometry are highlighted.

Application:

Utilized often in several industries, such as the automotive, pharmaceutical, and aerospace sectors.

Article 10 of ASME V:

Specifies the standards for leak testing in pressure vessels, covering allowed pressure drops, testing media, and acceptable leak rates.

4. Pre-Leak Testing Preparations

Preparations for pre-leak testing are necessary to provide precise and trustworthy leak detection in vacuum chambers. In addition to reducing the possibility of false positives, proper cleaning, sealing, and outgassing techniques also enhance the vacuum system's overall integrity. Each phase of the preparation process is broken down here:

1. Cleaning:

The vacuum chamber must be thoroughly cleaned before performing leak testing to get rid of any impurities that can affect the test's outcome. To remove residues like oils, dust, or particle matter, this procedure frequently uses solvent cleaning, ultrasonic cleaning, or even hand scrubbing. Any possible leaks can be precisely found without the involvement of external materials when the surface is clean.

2. Sealing:

For leak testing to yield accurate results, all joints and connections must be properly sealed. This involves verifying that flanges, O-rings, and gaskets are in good shape and torqued correctly. To maintain an airtight atmosphere and enable a more dependable and efficient leak detection procedure, new seals may need to be fitted.

3. Outgassing Procedures:

Outgassing is the process of releasing trapped gases from the vacuum chamber's materials before leak testing. To desorb any gases absorbed in the materials, this is usually accomplished by heating the chamber under a vacuum. Outgassing improves the accuracy of the leak testing results by ensuring that any leaks found are real and not just the consequence of outgassed materials.

5. Common Leak Testing Methods

There are vast range of methods available for leak tests but some most renowned tests are discussed below. Let's explore the details of each method.

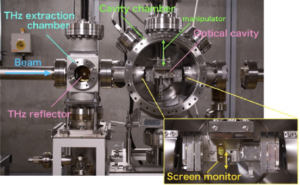

1. Helium Leak Testing

Helium is a light, tiny molecule that can readily pass through even the smallest leaks, which is the basis for how helium leak testing works. The technique finds leaks in containers or vacuum systems by using helium as a tracer gas. The non-toxic and inert nature of helium makes it perfect for leak detection.

Methodology: The component being tested is placed in a vacuum chamber and filled with helium. Any escaping helium is tracked in the atmosphere surrounding the test item using a mass spectrometer or other detecting tools. If helium is found outside the chamber, a leak is present.

Benefits:

- Sensitivity: Leaks as small as 10^-12 mbar·L/s can be detected by helium leak testing, which is extremely sensitive.

- Speed: The testing procedure is really quick and yields results right away.

- Non-destructive: It doesn't harm the systems or parts that are being tested.

- Versatility: Adaptable to a variety of substances and uses.

Applications:

The integrity of sensitive components and systems is ensured by helium leak testing, which is widely used in a variety of industries, including electronics, pharmaceuticals, automotive, and aerospace. It works especially well for testing high-vacuum systems, cryogenic applications, and hermetically sealed packages.

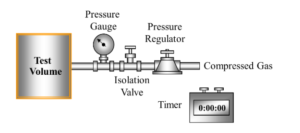

2. Pressure Decay Testing

The bedrock of pressure decay testing is the idea that, provided there are no leaks, a sealed system will continue to maintain a particular pressure. A leak is present when there is a pressure drop in the system over a predetermined length of time. The test gauges the amount of pressure drop, which is correlated with the leak's size.

Process:

- Preparation: A gas, usually nitrogen or air, is used to seal and pressurize the system or component to be tested to a specified level.

- Monitoring: For a predetermined amount of time, typically a few seconds to several minutes, the pressure is tracked.

- Analysis: The initial and final pressures are compared following the time gap. Stable pressure suggests integrity, but a large drop suggests a leak.

The Procedure of Pressure Decay Leak Testing

Benefits:

- Easy to Use: The process and setup are easy to understand and call for very little technical equipment.

- Affordable: When weighed against alternative leak detection techniques, pressure decay testing is comparatively less expensive.

- Non-destructive: Neither the system nor the tested component is harmed by the procedure.

- Rapid Outcomes: Offers prompt input regarding the tested system's integrity.

Application:

The automotive, medical, and consumer electronics sectors frequently utilize pressure decay testing to look for leaks in waterproof electronics, medical equipment, and fuel systems. Additionally, it is used in packaging, HVAC systems, and aerospace to guarantee component integrity and stop fluid or gas leaks.

3. Bubble Testing

The principle behind bubble testing is to visually observe bubbles that appear when a pressurized component is covered with the soapy solution or immersed in water to identify leaks. The presence and location of a leak are indicated by the formation of bubbles.

Method:

Preparation: Air or gas is used to pressurize the component.

Coating or Submersion: After that, it is either sprayed with a soapy solution or immersed in water.

Observation: The tester keeps an eye out for the formation of bubbles, which indicate the location of the leak.

Benefits:

- Easy to Use: Needs little setup or equipment.

- Affordable: It is among the least expensive techniques for finding leaks.

- Instant Visual Results: Leaks are immediately verified visually.

Applications:

Bubble testing is frequently used in HVAC maintenance, automotive repair, and plumbing to quickly and affordably locate leak locations in pipes, fittings, and seals.

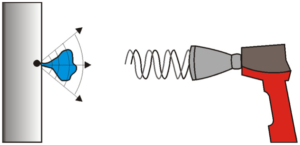

4. Ultrasonic Leak Detection

The principle behind ultrasonic leak detection is to find leaks by monitoring high-frequency sound waves produced when air or gas escapes through a hole. These sounds, which are frequently inaudible to the human ear, are picked up by ultrasonic detectors, which enable accurate leak location.

Process:

- Setup: The test area is scanned using an ultrasonic leak detector.

- Detection: The gadget picks up ultrasonic sound waves and transforms them into a visual indicator or audio signal.

- Analysis: To identify the precise position of the leak, the tester either utilizes a display or listens for fluctuations.

Benefits:

Non-Invasive: It doesn't need to come into contact with the test surface.

Precision: Capable of accurately locating even tiny leaks.

Versatile: Fits a range of gases and intricate system configurations.

Applications:

Ultrasonic leak detection is widely utilized in industries such as manufacturing, HVAC, and power generation for examining pipe systems, compressed air lines, and vacuum systems without the requirement for system shutdowns.

5. Vacuum Decay Testing

The pressure increase in a vacuum-sealed system over time is measured by vacuum decay testing. The presence of a leak will allow gas or air to enter the system, raising the pressure. A leak in the sealed component is indicated by this change in pressure.

Method:

- Sealing and Vacuuming: To eliminate any internal air or gasses, the component is sealed and then vacuumed.

- Monitoring: For a predetermined period, the vacuum level is kept constant and the system's internal pressure is tracked.

- Analysis: A consistent pressure denotes a satisfactory seal, but an increase in pressure points to the existence of a leak.

Applications:

The food, pharmaceutical, and packaging sectors frequently utilize vacuum decay testing to guarantee the integrity of blister packs, sealed containers, and sterile medical equipment while guarding against contamination and spoiling.

6. Halogen Leak Detection Method

The principle of the halogen leak detection technique is to find halogen-based substances, like refrigerants, that leak out. A detector that detects the halogen gas indicates the existence of a leak by sounding an alert or turning on a display.

Process:

Configuration: A halogen-based gas (often refrigerant gases like R-134a) is pumped into the component or system being tested.

Detection: Potential leak locations are probed using a halogen leak detector.

Response: When a leak is detected, the detector detects any halogen gas and sounds an alert.

Benefits:

Sensitivity: Identifies even minute halogen gas leakage.

Fast Results: Instant feedback makes it possible to locate leaks quickly.

Usability: The apparatus is easy to use and portable.

Applications:

To check for refrigerant leaks in air conditioners, refrigerators, and other appliances, the HVAC and refrigeration industries frequently utilize Halogen leak detection. Leak detection is another application for it in industrial refrigeration systems and automobile air conditioners.

7. Vacuum Gauge Leak Detection Method

The principle behind the vacuum gauge leak detection method is to find leaks by measuring pressure fluctuations inside a vacuum system. In the case of a leak, gas or air will enter, raising the vacuum chamber's pressure noticeably.

Method:

Setup: A vacuum pump is used to empty the vacuum system to a known pressure.

Monitoring: The pressure within the system is continuously monitored using a vacuum gauge.

Observation: Unexpected increases in pressure are a sign that gas or air is seeping into the system.

Benefits:

Non-Intrusive: During testing, there needs to be very little disruption to the system.

Data on system pressure is continuously provided by real-time monitoring.

Cost-effective: Usually just needs a normal vacuum pump setup and a vacuum gauge.

Applications:

To ensure the dependability and efficiency of high-vacuum machinery and procedures, vacuum gauge leak detection is frequently used in manufacturing and laboratory settings to assess the integrity of vacuum systems, vacuum chambers, and pipelines.

8. Radioactive Isotope Leak Detection Method

The principle of this technique is to use a radioactive isotope tracer to find leaks in a system. Any leaks are then detected using a radiation detector, which picks up radioactive emissions from isotopes that escape through leak spots.

Process:

Preparation: It involves injecting the system with a low-level, safe radioactive isotope.

Radiation detection: A radiation detector is moved around the system's exterior.

Observation: Any radiation outside the system that is detected points to the location and existence of a leak.

Benefits:

- High Sensitivity: Able to identify even the smallest leakage.

- Accurate location identification: Even in complicated systems, accurate location identification can pinpoint the exact position of leaks.

- Application in Challenging Circumstances: Works well in hot and humid conditions.

Applications:

Where other detection techniques might not be practical because of environmental factors or complexity, the radioactive isotope leak detection method is mostly utilized in the nuclear, chemical, and petroleum sectors to examine pipelines, storage tanks, and high-pressure systems.

6. Factors Affecting Leak Testing Sensitivity

Numerous factors can affect the sensitivity of leak testing; knowing these aspects is crucial to getting accurate and trustworthy leak detection results in a variety of applications.

- Pressure Difference: Since larger pressure changes make leaks easier to detect, higher pressure differentials between the test component's interior and exterior increase the sensitivity of leak detection.

- Type of Gas: The sensitivity is affected by the type of gas used in the test, such as air or helium. For example, helium is recommended in several procedures because of its small molecular size, which enables it to escape even through minute leaks.

- Temperature: Temperature changes have an impact on how materials expand and contract, which can alter the rate of leakage. Maintaining a steady temperature is essential for precise sensitivity in leak detection.

- Surface Condition: The integrity, cleanliness, and roughness of the surface affect the findings of leak detection. In general, leak detection accuracy is higher on smooth and clean surfaces.

- Equipment Sensitivity: The lowest detectable leak rate is directly impacted by the sensitivity of detectors, such as pressure gauges, ultrasonic detectors, and mass spectrometers. Equipment with a higher sensitivity yields more precise leak detection results.

- Test Duration: Longer test times, particularly for pressure decay or vacuum decay techniques, boost sensitivity because they give the gas more chance to escape through tiny leaks.

- Environmental Conditions: The sensitivity of leak testing may be impacted by external conditions that interfere with specific detection techniques, such as humidity, ambient pressure, and ventilation.

7. Challenges in Leak Testing

Some challenges that can impact output can occur while leak testing. Let's explore some details on it.

- Finding Small Leaks: It can be challenging to find tiny leaks, particularly in systems with high vacuum or low pressure, where conventional detection techniques might not be sensitive enough.

- Environmental Interference: Test accuracy may be impacted by outside variables such as temperature swings, humidity, and vibrations, which could result in false positives or negatives in leak detection results.

- Equipment Restrictions: The efficacy of leak detection equipment in certain applications may be limited by its sensitivity thresholds and inability to detect very low leak rates.

- Material Properties: Some materials, such as flexible or porous materials, might make leak testing more difficult because they can collect and release gases, which can produce inconsistent test results.

- Complex Geometry: Accurately identifying leaks in components with complex designs or difficult-to-reach locations can be difficult and call for specific tools or techniques.

- Time Restrictions: To reliably detect slow leaks, some leak testing techniques, like pressure decay or vacuum decay, call for long test durations, which can be lengthy.

8. Post-Leak Testing Procedures

Following post-testing procedures is crucial once leak testing is finished to make sure the vacuum system is fully restored, any problems are fixed, and the system is ready for dependable operation going forward.

➢ Repairs and Re-testing:

- Initial evaluation: To determine the type and extent of a leak, carry out an initial evaluation as soon as it is discovered. Determine which particular parts need to be repaired.

- Implementation of Repairs: To guarantee a good seal, make the required repairs, which can involve tightening fittings, changing seals, or rewelding joints.

- Re-testing: To confirm that the leak has been effectively fixed, do a follow-up leak test using the same methodology as the first test once repairs are finished. This guarantees that the system is safe to use and no longer leaks.

➢ Documentation and Reporting:

- Keeping Records: Keep thorough records of the leak testing procedure, including test findings, methods applied, and any irregularities noticed. Keep a record of all repairs, including the supplies and methods utilized.

- Reporting: Write a thorough report outlining the findings of the leak detection, the repairs made, and any additional testing that was done. This report may help in identifying patterns or repeating problems in the system and is used as a guide for future maintenance.

- Compliance and Quality Assurance: Assure that documentation satisfies legal and industry standards, enabling audits and guaranteeing adherence to safety procedures. Additionally, this supports continuous operations quality assurance procedures.

9. Industry-Specific Leak Testing Applications

Every industry uses different leak detection techniques based on its own operational requirements and standards. Here are a few instances:

- Automotive Industry

To guarantee efficiency and safety, leak testing is essential for air conditioners, exhaust systems, and fuel systems.

- Aerospace Industry

To ensure operational integrity and safety, leak testing is crucial for pressurized cabins, hydraulic systems, and fuel tanks in the aircraft industry. To find minor leaks that can impair aircraft performance, methods such as helium leak testing are used.

- Pharmaceutical Sector

Applications: Leak testing guarantees the integrity of medical devices, vials, and sterile packaging. To ensure product safety and adherence to health laws, leaks that potentially cause contamination are commonly found using vacuum decay and bubble testing techniques.

- Refrigeration and HVAC

To stop refrigerant loss and increase energy efficiency, leak testing is done on condensers, evaporators, and refrigerant lines in HVAC systems.

- The oil and gas sector

To guarantee safety and avoid environmental pollution, leak testing is essential for equipment, storage tanks, and pipes. Leaks that potentially endanger the environment and public safety are found using techniques like vacuum decay and radioactive isotope testing.

- The food and beverage sector

To avoid contamination and spoiling, leak testing is used to confirm the integrity of containers, seals, and packaging. Products are kept safe for eating through the use of vacuum decay techniques and bubble testing.

- Production

To guarantee operational reliability in production, leak testing is essential for pressure vessels, piping systems, and product assembly. Leaks in a variety of manufacturing processes are frequently found using techniques like pressure decay testing and ultrasonic testing.

10. Advances in Leak Testing Technology

The advancement in automation and detection techniques has transformed to provide more accurate, effective, and automated solutions, satisfying the ever-tougher demands of contemporary sectors. Let's discuss this in more detail.

1. Automatic Systems for Detecting Leaks:

Industrial settings can become more efficient by using AI and machine learning in automated systems to detect leaks quickly and accurately with little assistance from humans.

2. Improved Sensitivity Measurements:

Due to improvements in sensitivity, high-precision industries like pharmaceuticals and aerospace can now detect even the smallest leakage.

3. Alternatives to Helium Testing:

While helium is in short supply, substitutes like hydrogen-based testing and sophisticated pressure decay techniques are being created to preserve high sensitivity without helium.

4. Non-Destructive Methods of Testing:

New non-destructive techniques that provide accurate leak testing without sacrificing the integrity of delicate components include ultrasonic and infrared leak detection.

Carry-around Leak Detectors:

Field technicians can now accurately detect leaks for on-site inspections and maintenance thanks to the advancements in portable, handheld technologies.

11. How to Choose a Leak Testing Method

To guarantee reliable and precise outcomes, selecting the best leakage testing technique requires taking into account several elements. The following advice will assist you in choosing the best approach:

- Component Type: To find the optimal fit, take into account the system's or component's material and complexity.

- Leak Size: Determine the estimated leak rate and the sensitivity needed for your application (helium leak detection for minor leaks, for example).

- Environmental Conditions: Evaluate elements that could affect the testing procedure, such as temperature, humidity, and hazardous contaminants.

- Testing Goals: Verify adherence to industry norms and take the production stage into account (in-process vs. final testing).

Conclusion

The precision, effectiveness, and adaptability of leak detection across a range of industries have been greatly enhanced by developments in leak testing technologies. While automated systems and IoT integration allow for continuous monitoring and predictive maintenance, improved sensitivity sensors, real-time data analytics, and non-destructive approaches have made leak testing more accurate and less intrusive.

These developments will support safety, quality, and cost-effectiveness as technology advances, guaranteeing that systems continue to be dependable and adhere to strict industry requirements. This blog was helpful for you? Don’t forget to share your thoughts by commenting below.