Welding quality concerns keeping you up at night? Visual inspection serves as your first defense against costly defects, catching problems before they become catastrophic failures.

Visual testing is the foundation of any comprehensive non-destructive testing (NDT) strategy, identifying surface defects like cracks, porosity, and improper weld profiles immediately after welding completion. While it can't detect internal flaws, its cost-effectiveness and immediate results make it essential before implementing more sophisticated NDT methods.

Professional conducting visual weld inspection

Professional conducting visual weld inspection

When we talk about Non-Destructive Testing (NDT), many people immediately think of sophisticated equipment and complex procedures. But in our experience at our CNC machining facility, the most valuable NDT method is often the simplest: visual inspection. Let me show you how this fundamental technique fits into a comprehensive testing strategy and why it should never be overlooked.

What Types of Weld Defects Can Visual Testing Detect?

Worried about the quality of your welds? Visual inspection can immediately reveal surface problems that could lead to component failure and costly rework.

Visual testing can detect numerous surface weld defects, including cracks, porosity, undercut, overlap, insufficient throat, excessive reinforcement, incomplete fusion at the surface, and dimensional inaccuracies. These surface issues often indicate deeper problems and provide valuable information about the quality of the welding process.

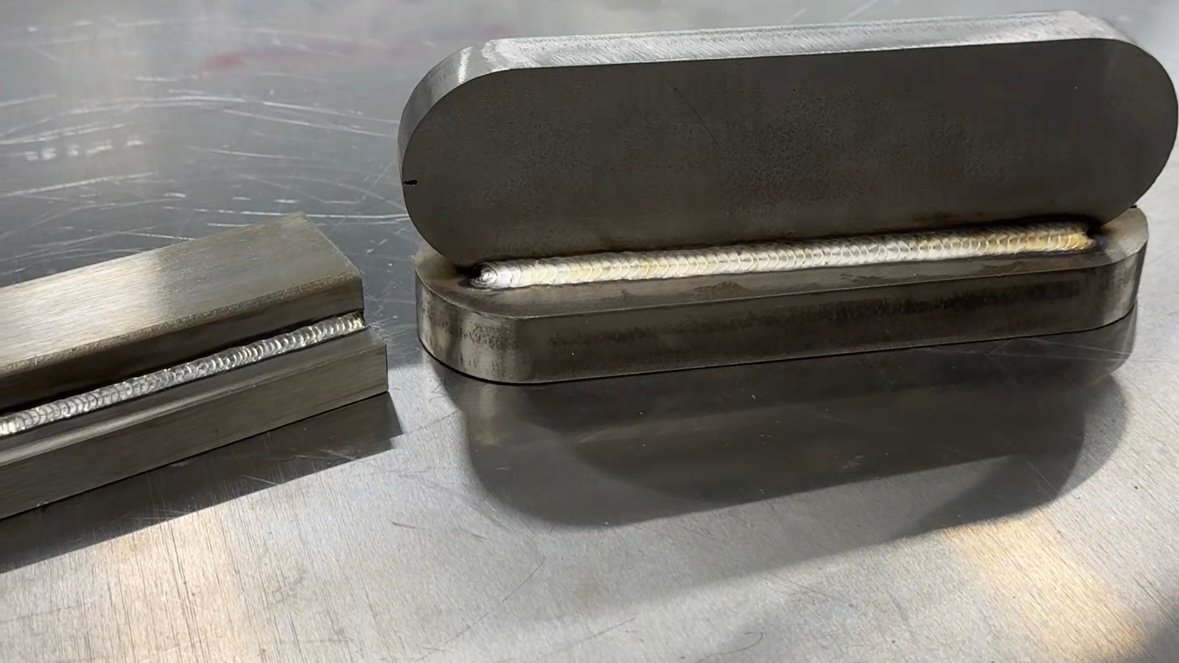

Common weld defects identified through visual inspection

The power of visual inspection lies in its ability to catch a surprising range of defects despite its simplicity. In our workshop, we've implemented systematic visual inspection procedures that have prevented countless quality issues from progressing further. Let me break down the specific defects that a trained eye can identify:

Surface-Breaking Defects

Visual inspection excels at identifying defects that break the surface of the weld. These include:

- Cracks: Linear discontinuities that represent the most serious type of weld defect

- Surface porosity: Gas pockets or voids that appear as small, rounded holes

- Undercut: A groove melted into the base metal adjacent to the weld toe

- Overlap: Excess weld metal flowing onto the base metal surface without fusion

Dimensional and Profile Issues

Beyond defects, visual testing verifies if the weld meets dimensional specifications:

- Weld size: Ensuring the weld meets specified dimensions (leg length, throat thickness)

- Weld profile: Checking for proper contour and transition between weld and base metal

- Misalignment: Detecting offset between joined components

- Excessive reinforcement: Identifying too much weld metal buildup

| Defect Category | Examples | Detection Reliability |

|---|---|---|

| Surface Breaking | Cracks, porosity, slag inclusions | Very High |

| Profile Issues | Undercut, overlap, excessive reinforcement | High |

| Dimensional | Size, alignment, position | High |

| Appearance | Spatter, arc strikes, discoloration | Very High |

How Do Industry Standards Affect Visual Inspection Criteria?

Confused about which acceptance standards apply to your products? Industry-specific codes determine the acceptable limits for weld imperfections, directly impacting your quality control process.

Different industries follow specific standards for visual inspection criteria, such as AWS D1.1 for structural steel, ASME Section IX for pressure vessels, and ISO 5817 for general welding quality. These standards define acceptance levels for various defects, dictate inspection procedures, and determine qualification requirements for visual inspectors.

Comparing welds against industry standard acceptance criteria

In our manufacturing operations, we've had to navigate multiple standards depending on which industry our client operates in. The application of these standards has a significant impact on how we approach visual inspection and the criteria we use to determine acceptability. Here's how different standards influence visual inspection practices:

Acceptance Criteria Variations

Different standards have varying levels of strictness for the same defects. For instance, aerospace welding standards (AWS D17.1) are generally more stringent than general structural welding standards (AWS D1.1). When we produce vacuum chambers for semiconductor equipment, we follow stricter standards than when creating general industrial components.

Quality Levels Within Standards

Many standards, such as ISO 5817, define multiple quality levels (B, C, D) that allow for different acceptance criteria based on the application's criticality. This hierarchical approach means visual inspection can be tailored to the specific requirements of the component's function.

Documentation Requirements

Standards don't just define what constitutes an acceptable weld—they also specify:

- How inspection results must be documented

- Required qualification levels for inspectors

- Lighting requirements and viewing angles

- Tools and gauges that must be used

| Standard | Industry Application | Key Focus Areas | Typical Quality Levels |

|---|---|---|---|

| AWS D1.1 | Structural Steel | Fusion, size, profile | 3 levels (stringent to basic) |

| ASME Section IX | Pressure Vessels | Safety-critical aspects | Accept/Reject based on service |

| ISO 5817 | General Manufacturing | Comprehensive defect listing | B (stringent), C (intermediate), D (moderate) |

| AWS D17.1 | Aerospace | Precision and consistency | Class A, B, C (A being the strict) |

When Should You Supplement Visual Testing with Other NDT Methods?

Concerned about hidden defects lurking beneath the surface? Visual testing's limitations make it necessary to incorporate additional NDT methods for critical components where internal flaws could be catastrophic.

Visual testing should be supplemented when inspecting safety-critical components, when internal defects are a concern, when code compliance requires it, or when historical data suggests potential subsurface issues. Methods like radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and penetrant testing (PT) provide complementary capabilities beyond visual limitations.

Supplementing visual inspection with ultrasonic testing

In our factory, we've learned that relying solely on visual inspection can sometimes be inadequate. While it's always our starting point, we've established clear guidelines for when additional NDT methods are necessary. This approach has helped us maintain quality while optimizing testing costs. Let me share our experience-based framework for supplementing visual inspection:

Application-Based Considerations

The end-use of the component often dictates when additional testing is required. For instance, when we manufacture parts for:

- High-pressure applications: Components that will contain pressurized fluids or gases require ultrasonics or radiography to verify internal integrity.

- Dynamic loading: Parts subject to fatigue or cyclic loading need magnetic particle or penetrant testing to detect tiny surface-breaking cracks.

- Critical safety systems: Components where failure could lead to injury or significant damage require comprehensive testing beyond visual.

Defect Detection Limitations

Each NDT method has specific defect detection capabilities:

- Radiographic Testing (RT): Ideal for detecting volumetric defects like porosity and inclusions

- Ultrasonic Testing (UT): Excellent for finding planar defects like lack of fusion and cracks

- Magnetic Particle Testing (MT): Best for surface and near-surface cracks in ferromagnetic materials

- Penetrant Testing (PT): Perfect for fine surface cracks in any non-porous material

Economic Considerations

We approach supplementary testing with a risk-based perspective:

| Component Risk Level | Visual Inspection | Supplementary Methods | Cost-Benefit Balance |

|---|---|---|---|

| Low Risk | Comprehensive | Rarely needed | High ROI on visual alone |

| Medium Risk | 100% coverage | Sampling approach with other methods | Balanced approach |

| High Risk | Initial screening | 100% coverage with appropriate methods | Cost justified by risk mitigation |

Why Is Visual Testing Considered the First Line of Quality Control?

Wondering if sophisticated testing technology has made visual inspection obsolete? Despite technological advances, visual testing remains the foundation of quality control due to its immediacy, cost-effectiveness, and ability to catch obvious defects early.

Visual testing is the first line of quality control because it's immediately available following fabrication, requires minimal equipment, provides instant feedback to welders, and can identify process issues before they become widespread. It's also the most cost-effective NDT method and can prevent unnecessary advanced testing by catching obvious defects that would cause rejection anyway.

Visual inspection as the first line of quality control

In our daily operations, we've seen firsthand how visual inspection creates a strong foundation for our quality control system. When we established our vacuum chamber production line, we implemented a multi-stage inspection process that always begins with a thorough visual examination. The benefits have been substantial and measurable. Here's why we consider visual testing indispensable:

Immediate Process Feedback Loop

Visual inspection provides real-time feedback that helps maintain consistent quality. When our welders receive immediate visual inspection results, they can:

- Adjust welding parameters before continuing production

- Address technique issues that might be causing defects

- Verify that equipment is functioning properly

This rapid feedback loop has reduced our rework rate by approximately 40% in the past year alone.

Economic Efficiency

The cost-effectiveness of visual testing cannot be overstated. Consider these comparative costs from our operations:

| NDT Method | Equipment Cost | Inspection Time per Joint | Operator Training Requirements | Relative Cost per Inspection |

|---|---|---|---|---|

| Visual (VT) | $500-1,000 | 2-5 minutes | Moderate | 1x (baseline) |

| Penetrant (PT) | $2,000-3,000 | 30-45 minutes | Moderate | 5x |

| Magnetic Particle (MT) | $5,000-15,000 | 15-30 minutes | Moderate-High | 7x |

| Ultrasonic (UT) | $15,000-50,000 | 10-30 minutes | High | 10x |

| Radiographic (RT) | $50,000-200,000 | 30-60 minutes | Very High | 20x |

Gateway Testing Function

We use visual testing as a gateway before more expensive methods. For example, in our automotive parts production:

- All welds undergo visual inspection (100% coverage)

- Only welds passing visual inspection proceed to other NDT methods as required

- This screening approach has reduced our advanced NDT costs by approximately 25%

Additionally, visual inspection often reveals underlying process issues that might be causing defects. On multiple occasions, our inspectors have identified improper shielding gas coverage or contaminated base materials based purely on the visual appearance of welds, preventing potentially hundreds of defective parts.

Conclusion

Visual inspection forms the foundation of any comprehensive NDT strategy, offering immediate, cost-effective detection of surface defects. While it must be supplemented with other methods for internal flaws, its role as the first line of quality control remains irreplaceable.