Heat treatment is a crucial step in the manufacturing process, despite the fact that most people are unaware of what it is. This is related to the reasons that heat treating a metal piece enables the material to be strengthened so that it can endure wear and tear better. In order to harden a metal or alloy, heat treatment includes heating it to a certain temperature and then cooling it.

Aircraft, autos, hardware like saws and axes, computers, spacecraft, military, and the oil and gas sector are a few major areas where heat treatment is significant. A metal or alloy's characteristics can be altered by heat treatment at various points during the manufacturing process.

Metal alloys that have undergone heat treatment are capable of acquiring the desired mechanical characteristics. The temperature and length of the heat treatment affect a lot of the phase transformations that take place. To create high-quality parts and components with the desired qualities, accurate temperature and timing management are required.

So, you don’t think it is necessary to know what processes are involved in four fire heat treatments, and how does it impact the properties of the materials. Of, course yes. Let’s explore this in detail.

How does Four Fire Heat Treatment work?

All heat-treating procedures include putting metal through a specific time-temperature cycle, which may be broken down into the following three steps:

- heating,

- holding at temperature (soaking),

- and cooling.

Although every scenario is different, some essential goals can be stated. Unless steel is significantly stressed, as is imparted by intense cold working or prior hardening, the pace of heating is not particularly relevant. The rate of heating should be slow in such circumstances. This is frequently impractical because furnaces may already be at operational temperatures. However, putting cold steel in a hot furnace may result in distortion or even fracture.

A steel's structure and qualities are determined by its cooling rate, which is in turn influenced by things like mass, quenching media, etc. It is important to understand that, the rate of cooling will be slower with thicker the section, regardless of the cooling method utilized.

Annealing

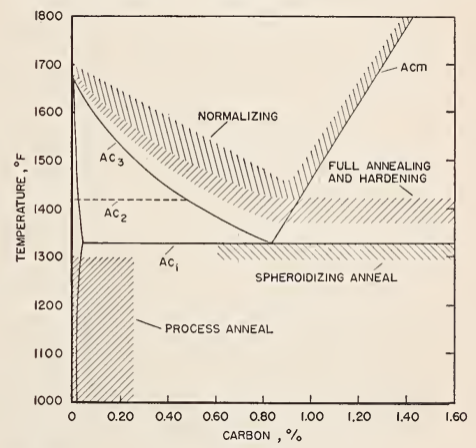

Annealing is a heating and cooling procedure that typically results in softening. This treatment also covers procedures designed to change mechanical or physical characteristics, create a specific microstructure, or eliminate gases. The material being annealed and the intended use of the treatment determines the temperature of the operation and the rate of cooling. In annealing heating the specimen above or below the upper critical line. An annealing process consists of three main stages.

- recovery.

- recrystallization

- grain growth

How these three stages influence the annealing process and how material properties changes during these steps has worth for you to know.

Stage of Recovery

In the recovery stage, the material is heated in a furnace or other heating device to a temperature that releases its internal stresses.

Stage of Recrystallization

The material is heated during the recrystallization phase to a temperature above recrystallization but below melting. This results in the formation of new grains with no preexisting stress.

Stage of Grain Growth

The new grains mature completely during grain growth. Allowing the material to cool at a specific rate can control its growth. These three steps together produce a material with increased ductility and decreased hardness. There are different types of annealing processes on the basis of temperature heating and rate of cooling, annealing treatment can be categorized in the process as below

- Full annealing

- Process annealing

- Spheroidizing

Normalizing

In normalizing the steel is heated to a temperature above the Ac3 or the Acm and then is cooled in normal air. The treatment's primary goal is to nullify the effects of any prior heat treatment, including the coarse-grained structure that can occasionally result from high forging temperatures, as well as any cold working, and to ensure that austenite will be uniform upon reheating for hardening or full annealing. Depending on the steel's composition, the resulting structures are either pearlite or pearlite with extra ferrite or cementite.

Temperature range of treatments

Quenching

Quenching is basically used to enhance the hardness of material above a specific point.

The material is heated above the upper critical temperature line Ac3 or Acm then sudden cool. In cooling air, oil, water, or other media, are used to cool material quickly. In order to increase hardness, this quick cooling procedure known as quenching is typically employed for stainless and high-alloy steels. This process is in cast irons and steels alloyed with metals like nickel and magnesium, hardening is frequently used.

Tempering

Tempering is a heat-processing technique that increases the toughness of hard, brittle steels so that they can withstand processing without breaking. The quenching process is followed by this treatment. Without tempering, a quenched metal is typically too brittle to be used further. It will be uniformly heated between 90 to 260°C, maintained at that temperature for the required amount of time, and then slowly cooled, depending on the alloy used

Methods of Four Fire Treatment

The four fire heat treatment is a skilled method for modifying the metal's characteristics by managing the rate of diffusion inside the microstructure. This implies that different microstructures form in the same alloy depending on the cooling rates. As the austenite cools quickly, it changes into martensite, a hard, brittle crystalline structure where the alloying elements are trapped. This structure requires tempering to precipitate intermetallic particles in order to reach the highest level of strength and hardness.

But, how four fire heat treatments are performed? How does material change its properties during treatment? Let’s explore more.

Annealing:

It involves heating metal in a furnace above the temperature at which it will recrystallize and allowing it to cool down inside the furnace. The material is first heated to a higher temperature (say, 912–915°C for cast iron or steel). Subsequently, The substance is soaked at that temperature for a short period of time. In the third step, the material is again allowed to cool inside the furnace while the temperature is decreased. Strength, ductility, and good elongation qualities are all improved by annealing.

Normalizing:

Similar to annealing, however after the soaking stage, the material is removed from the furnace and allowed to cool in the open air. Because the material has distinct cooling zones, the characteristics are slightly less favorable than during annealing.

Quenching:

Quenching is the process of rapidly cooling a material that has been heated above the temperature of recrystallization in an oil, or water bath. Quenched materials exhibit a martensite matrix structure. The material gets much harder, more brittle, and resilient to wear and shocks. There is better abrasive resistance, but it cannot withstand creep and impact stresses

Tempering:

It is a heat-treatment procedure that is often carried out following quenching. The material is heated during the process to a temperature below the recrystallization value and maintained for a short period of time. Through this procedure, internal stress is reduced and the hard material's ductility is slightly improved. This procedure is typically applied to tool steels.

It is possible to follow a heat treatment technique that will give a certain alloy the necessary mechanical properties at room temperature, but doing so requires knowledge of the phase changes that take place inside metallic alloys.

The difference in Four Fire Treatment

Full annealing is used to soften strain-hardened material previously and remove the last room temperature microstructure. This is typically done to make further deformation processing or machining easier. The entire annealing procedure involves heating the component to the appropriate temperature and then progressively cooling it in the furnace as it moves through the transformation range.

Although normalizing is Similar to annealing, however after the soaking stage, the material is removed from the furnace and allowed to cool in the open air. Because the material has distinct cooling zones, the characteristics are slightly less favorable than during annealing.

Whereas, quenching is done to get hardenability that is produced due to martensitic or possibly bainitic microstructures; these microstructures require quick cooling rates from austenite to prevent pearlite development. Thus, the material is quickly cool to below 500 °C from the austenitizing temperature in order to prevent the formation of pearlite.

The term "tempering treatment" refers to the process of cooling down the steel at a specific pace after quenching, hardening, or normalizing being submerged for a while below the critical temperature. Tempering is performed to produce the required combination of strength, hardness, and strength or relieve the stress or brittleness of fully hardened steel. Tempering and quenching are required to make tough parts.

Phase changes

As heat treatment is performed, it brings a lot of changes at the atomic level that cause phase changes. It is important to know, what phase changes occur during treatments and how properties change?

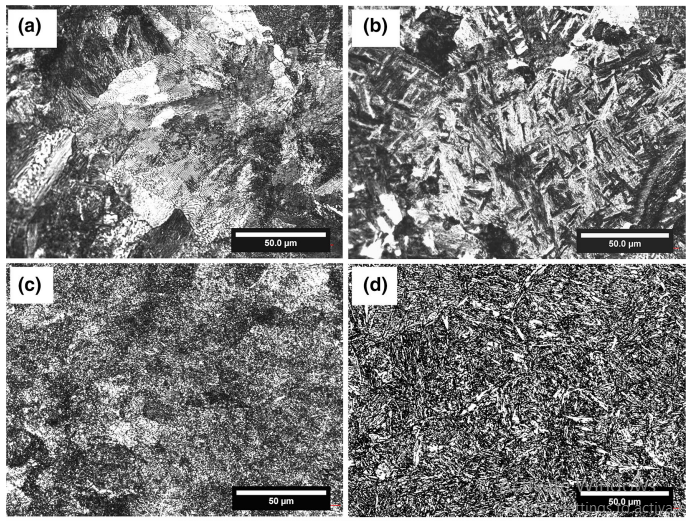

Although, It is necessary to heat treat hypoeutectoid steel to a temperature just over AC3 in order to thoroughly anneal it. The material is kept at the annealing temperature for about an hour, usually, and then slowly cooled in the furnace. The ferrite-pearlite microstructure formed.

Annealing is carried out for hypereutectoid materials above the AC1 temperature. It consists of coarse lamellar pearlite surrounded by proetectuoid cementite. An improved grain is achieved through annealing, as well as softening, improving electrical and magnetic characteristics, as well as machinability occasionally.

A fine, equiaxed austenite grain size and subsequent coarse pearlite microstructural scale produced by normalizing is easier to process or heat treat and leads to an increased toughness.

Quenching results in the highest hardness levels. This results from the creation of significant quantities of martensite from austenite, as shown in the microstructure. Always, quenching followed by tempering results in a decrease in hardness and an increase in toughness.

The microstructure changes during the normalizing process, first becoming austenite and then becoming quenched martensite during the succeeding air cooling phase]. During the tempering process, the quenched martensite changes into tempered martensite.

Microstructure after heat treatment (a) pearlite (b) bainite (c) Spherodized

(d)tempered martensite (e) Martensite

Material Properties

Metal alloys that have undergone heat treatment are capable of acquiring the desired mechanical properties. The temperature and length of the heat treatment affect a lot of the phase transitions that take place. To create high-quality parts and components with the desired qualities, accurate temperature and timing management are required.

Without heat treating metal, especially steel, metal components for anything from computers to airplanes wouldn't work correctly or might not even exist. Particularly non-ferrous metal components would be significantly less durable. Heat treatment is a process that strengthens metals like bronze, brass, titanium alloys, and aluminum.

Another crucial process parameter is the rate of cooling after high-temperature heat treatment. Pearlitic microstructures will be tough and ductile as a result of slow cooling. In order to create steels with a combination of high-strength and high-toughness tempered martensitic microstructure after quenching will produce high-strength and low-toughness martensitic microstructures.

Recovery and recrystallization mechanisms take place in distorted microstructure when the annealing temperature is raised. The alloy loses tensile strength and yield strength while gaining elongation. Annealing can soften materials and make them more machinable. Refine the grain, tweak the structure, and get rid of imperfections.

Eliminate residual tension, stabilize size, and lessen the chances of deformation and cracks. Uniformity in the structure and content of the material, improved material performance for upcoming heat treatment. Whereas, Hardness, yield strength (YS), and ultimate tensile strength (UTS) all increased with normalization and reduced with tempering.

But, the mechanical properties of the metal, such as shear strength, yield strength, hardness, ductility, and tensile strength, can be precisely balanced through tempering to achieve any number of different combinations of properties, making steel useful for a wide range of applications.

Effect of tempering on ultimate tensile strength

To fulfill the numerous demands of various mechanical components and tools, quenching can significantly increase the steel's rigidity, hardness, wear resistance, fatigue strength, and toughness. It can also be quenched to meet additional unique physical and chemical characteristics, such as ferromagnetism and corrosion resistance of some special steels.

Materials used for Four Fire

Heat treatment can be used on all metals and alloys. Steel is thought to be the basis of roughly 80% of all industrial heat treatment procedures, although many other ferrous and non-ferrous metals are also heated and cooled for related purposes. While some heat-treated non-ferrous metals include aluminum, copper, brass, and titanium, ferrous heat-treated metals frequently include cast iron, alloys, stainless steel, and tool steel.

Alloys of aluminum undergo annealing or solutionizing, quenching, and age-hardening. Alloys made of copper, brass, and bronze are also heat-treated through annealing and age-hardening. Steels can be heat treated via age hardening, age quenching, and annealing.

Martensitic stainless steels are frequently employed in industrial applications where there is a strong demand for higher strength, hardness, and wear resistance. Such steels' performance is greatly influenced by the tempering process. The stainless steel used for the heat treatment process is categorized into three groups below

Group I: hardenable chromium steels(Martensitic and magnetic).

Similar to the majority of lower alloy steels, these steels respond to heat treatment and can generate a wide range of mechanical properties with the right thermal treatment. Because it promotes increased brittleness, the tempering range of 700° to 1000° F. should be avoided.

Group II—Chromium Steels That Cannot Be Hardened (Ferritic and Magnetic)

Heat treatment cannot really harden these steels. In the annealed condition, they reach their peak levels of softness, ductility, and corrosion resistance.

Group III NonhardenableSteels made of chromium, nickel, and manganese (austenitic and nonmagnetic)

These steels can't be heat treated to get harder because they are fundamentally nonmagnetic. Many different mechanical properties can be developed through cold working, and some of these steels may even become mildly magnetic when they have been substantially cold worked. In order to achieve the greatest degree of softness, ductility, and corrosion resistance, they are annealed by rapidly cooling (air or water) from high temperatures.

Industrial Applications

How four fire treatments is worthful for industrial application? What is its basic application?

well, In many large-scale manufacturing industries, including the automotive, transportation, aerospace, building, marine, military, material handling (casting, forging, equipment), and medical and pharmaceutical sectors, heat treatment is an essential technique. Significant benefits of heat treatment include decreased cost, weight, and noise as well as improved strength, dependability, toughness, performance, and resistance to wear and fatigue.

Therefore, heat treatment is used to prepare the metal parts of powertrains, engines, turbines, farms, mining, forestry, and construction equipment. For instance, to achieve the needed characteristics in the aerospace industry, steel, and aluminum alloys may go through five or perhaps more distinct heat treatment operations.

Photo by Philipp Potocnik on Unsplash

Profiles, shafts, discs, gears, plates, and other shapes are among the most popular heat-treated metal geometries. Improving heat treatment procedures for eradicating material issues is of tremendous importance and value to the related sectors a valuable task for academics and scientists.

The Bottom line

Heat-treating metal beforehand reduces corrosion, which means that replacing expensive metal parts later on or more frequently won't be necessary. Heat-treated metals are frequently stronger than non-heat-treated metals. As a result, issues are avoided and equipment operates more effectively and affordably.

In four fires of heat treatment quenching, tempering, normalizing, and annealing is involved. By balancing the proportions of hard martensite, ductile ferrite, and pearlite throughout heat treatment, strength and ductility will be guaranteed.

Is this blog was helpful for you or you have any other view about it. Just let us know by commenting below.