Industry systems require various components and one of them is a flange accessory. Flange accessories act as important elements in establishing strong and reliable connections when it comes to piping systems. The incorporation of these accessories promotes safety, dependability, and system functionality across various industries including oil, gas, and pharmaceuticals. In this guide, we will look into pipe flange accessories deeply, how they work, what are the standard types, functions, applications, and more. So, stay connected!

1) What are Flange accessories?

“Flange accessories are extra components which flank on flanges to provide adequate and reliable joint connection to a section of piping fittings.”

These accessories work hand-in-hand with flanges in order to achieve leak-tight joints, and proper alignment as well as produce the ability to withstand excessive pressure and temperatures. Some of the items or components of flanged joints are bolts, nuts, gaskets, and spacer rings.

Nuts and Bolts provide the clamping force that holds together two or more flanges. Gaskets provide a sealing capability across the interfaces between two mating flanges to prevent any leakage of gases or liquid from the joint. Spacer rings control the spacing between the two or more flanges used in a joint.

All these factors work in tandem to make sure that the piping systems are reliable and functional. Moreover, they prevent issues such as leaks, enhancing safety and minimizing the need for costly modifications.

2) How do flange accessories work?

Now, it is clear that flange accessories are critical to creating a bolted pipe connection between piping components. Their operation depends on each component’s precise operation inside the system. Let’s discuss this thoroughly;

➢Compression Mechanism: Bolts and nuts apply a consistent clamping force to bolt the respective flanges. As a result of this force application, the gasket balloons out and fills tiny cavities or uneven surfaces of flange faces. Because of the compressive nature of the gasket, it prevents the flow of fluid across the piping joint. Ultimately, it strengthens the bonding between the system and the joint of piping.

➢Alignment: Spacer rings are essential to permit the correct orientation of the two flanges. Flanges need to be rotated to the standard angle about the bearing easily without causing any great internal pressure on the bearing. Stress that is excessive could lead to joint separation or leaking.

➢Load Distribution: The tightening of all bolts helps to balance the stresses at the flange joint to avoid the bulging of the gaskets and the deformation of the flange. This helps avoid overly concentrating stresses at one point. You know overstress can lead to the folding of gaskets or the breaking of bolts. The correct load balance prevents the formation of spaces between the locking and the seal. Thus, it prevents leakage from the framework.

3) Face types of Flange accessories

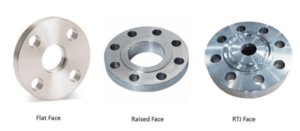

Piping systems require guarantees on leak-proof flanged connections and this is where flange faces come in, since they are referred to as the surfaces that contact gaskets. There are several types of flange faces, some common types are mentioned below;

i) Raised Face (RF): A fairly common configuration in a lot of industries. It is constructed with a slightly raised ring around the bore which compresses and enhances the pressure of the gasket.

ii) Flat Face (FF): Generally, these are applied on low-pressure, low-temperature applications that include nonmetallic or made out of cast iron components. They come fitted with flat surfaces that require full-face gaskets.

iii) Ring-Type Joint (RTJ): These are designed for applications that operate in high pressure and temperature ranges such as those encountered in the oil and gas industry. When it is bolted, the ring is compressed into the groove, creating a metal-to-metal seal in RTJ flanges.

iv) Tongue and Groove (T&G): This system includes one flange with a raised ring tongue and a groove depression on the other flange.

The gasket is accommodated in the groove to ensure it is properly aligned and does not come off out of position. T&G flanges can be utilized in high-temperature and high-pressure equipment.

v) Male and Female (M&F): Like T&G, These flanges also possess corresponding male and female facets whereas the male is raised and the female is recessed. Within the recess, the gasket is situated which reduces the risk of a blowout and ensures accurate alignment. M&F flanges are installed in medium to high-pressure applications.

The type of a flange face that is selected, is determined by the pressure, temperature and the fluid that is being conveyed. These considerations if properly made will guarantee the safety and reliability of the system.

4) What are the functions of Flange accessories

Flange accessories bring many features which are crucial for the continuity and security of the piping works, these functions include;

➢Sealing: The most important role of the flange is played by gaskets. They prevent the flanges from leaking. In other words, they ensure a reduced risk of hazarding the leakage of any gases or fluids so as to make the system safe.

➢Strengthening: Flange accessories, in particular bolts and nuts, are the increasing mechanical strength of the connection between flanges. This is necessary in systems of high pressure as the influx of force at the connection is greatly high.

➢Alignment: Spacer rings and other alignment components guarantee that the flanges are placed in the proper position before fastening. You know misalignments can lead to a system failure or leakages. So, this minimizes the bending moment angle which in turn prevents misalignments.

➢Safety: Flange accessories are built to integrate the system together and avoid extreme conditions for instance high pressure or temperature. The purpose is to prevent, for example, bolt neck engagement or more serious bolt necking.

These functions have indicated why it is important to get the right bolting flange accessories and perform the required maintenance for effective long run of the system.

5) What are the applications of Flange accessories?

A variety of flange accessories are required across industries for multiple piping and connection systems. Some of the most common applications include:

●Oil and Gas: Flange accessories are designed to seal the unit pipes in crude oil, natural gas, and refined products industries. Flange accessories guarantee a leak-proof connection there.

●Chemical Processing: A flange bolt also proves crucial in the chemical industry as it allows for the storage of corrosive materials. To use in such sensitive environments, they are made from stainless steel or alloy steel which ensures durability.

●Power Generation: In all high-pressure steam system turbines and boilers, flange bolt accessories are important tools to secure the piping connection to the respective units.

●Water Treatment: Flanges are an integral part of the water treatment systems, filtration and distribution systems. They can be used to join together sewer and water pipes to protect the networks.

●Pharmaceuticals: Flange accessories are disturbing concerns in the Pharmaceutical hazardous industry as they allow work processing equipment and connection points not to contaminate the product.

●Food and Beverage Industry: Flange accessories help in safely connecting equipment used for food processing and beverage production. Their sanitary designs prevent contamination and ensure that the food products meet safety standards.

●Mining and Minerals: In mining, flange accessories are used to connect pipelines carrying minerals, chemicals, or slurry. The accessories are made to withstand harsh conditions and maintain a reliable connection under heavy pressure.

●HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, flange accessories are used to join ducts and pipes securely, allowing for efficient air and fluid transport while preventing leaks.

●Construction: Flanges play a role in construction for connecting various pipes used in plumbing, heating, and water supply systems, ensuring long-lasting, leak-resistant connections.

The global flange market is estimated to grow at the rate of 5% every year which is attributed to the rising need for such tools.

6) Final words

So, flange clamping ensures the safe and efficient operation of industrial systems. Their role in ensuring proper tight seals and good geometric alignment together form an integral function for dependable service. With the right selection of accessories, maintenance is at a minimum and the performance of the systems is improved. Since the demand for tough and long-lasting solutions increased, flange accessories continue to be one of the most important aspects of the protection of industrial pipe fittings from destruction.

At BaiChuan CNC, we specialize in a range of services including CNC machining, welding, mold making, 3D printing, and reverse engineering. Whether clients need precision parts, custom molds, or innovative solutions, we offer top-quality craftsmanship and cutting-edge technology to bring their projects to life. Contact us today to explore how we can assist with your next venture!