1.0 Introduction

The sorts of parts that can be created and machined are expanding because to advancements in manufacturing technologies. Curves, as well as pieces with sophisticated curves and complex 3D forms, are as simple to manufacture as straight lines. Greater automation has resulted in increased uniformity and quality, as well as a reduction in the number of mistakes. CNC also provides for greater flexibility in how workpieces are held, minimizing the need for costly jigs or fittings that are necessary on traditional machines. Small quantities, short manufacturing runs, and parts that must be delivered quickly may all be accommodated.

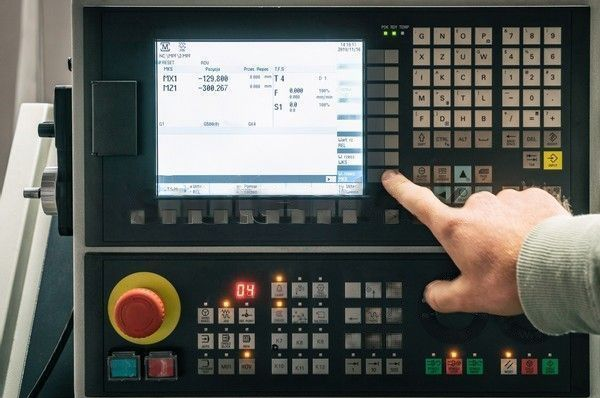

1.10 CNC Precision Machining

CNC Milling Machines are computer-controlled cutting tools that precisely eliminate materials from a workpiece. It can cut, grind, and turn a variety of materials, although it is most commonly used for metals. Precision is what makes CNC machining so appealing. It's also ideal for ordinary production, as it provides very precise cuts in a short amount of time. Tolerances are used by CNC machines to figure out how much an item can stray from standard specifications. Some items, such as those used in aerospace and medicine, are likely to demand stricter tolerances than toys or furniture.

2.0 Optimizing CNC Milling Accuracy and Precision

The following tips will help to improve the precision and accuracy of the CNC Milling.

2.10 Reduce Tool Distortion

Tools that are at their prime endure longer and perform better. Tools that have been distorted must be replaced on a regular basis. When it comes to taking care of CNC machining equipment, predictive maintenance eliminates needless maintenance while also minimizing unexpected downtime due to a machine malfunction.

Preventive maintenance is still preferred over reactive maintenance. If no data is available to estimate the ideal times to service your equipment, then just following the manufacturer's preventative maintenance requirements will suffice. When performing routine maintenance, it is recommended to check the condition tools, filters, and spindles. If you use the device often, these parts may need to be replaced frequently. Choosing harder tools where possible also reduces tool wear.

Despite the fact that the most durable tools have similar price tags, tools that stay sharp provide more exact machining solutions. No matter how precisely you set up the machine, dull, worn-out tools can't attain high levels of accuracy.

2.11 Understand the Material Properties

During machining, material parameters including tensile strength, yield strength, Young's Modulus, and thermal expansion of the workpiece must be taken into account. When exposed to the same cutting force, a low yield strength material, for example, would deform more than a high yield strength material.

2.12 Component mechanical design

The precision and accuracy of the job is affected by the intricacy of the part design as well as the number of sides a machine operates on. When you have a machine that works on more axes, you do not need to worry about mistakes made during multiple setups. Because the usage of a 5-axis machine eliminates additional setups,

If you currently have a three-axis machine, you may integrate work on five sides by adding a two-axis table to move the part. This 3+2 design is the simplest and most cost-effective approach to add machining on multiple sides of the component. However, if you need to work on heavy or massive pieces, the table may not be able to support them, and switching to a five-axis machine may be the best solution.

2.13 Assembly Design

Tool presetters can help with precision while setting up the machine for the job. In less than a minute, these add-ons determine the tool placement accuracy. In comparison, it takes a machinist more than an hour to configure 15 tools for a job using a touch probe. Your precision improves when you use presetters because the system can determine the exact location of the tool for more precise cutting.

Your work will not be harmed by errors made during manual setting because of the more exact placement of the instruments. Despite popular belief that tool presetters are only useful for large operations, any jobsite that changes tools regularly will benefit from their use.

Work holding devices can prevent accidents, and an electro-permanent magnet can help if you have a metal item. When working with thin components that may slide or bend during cutting or milling, using an electrically activated magnet to retain them is a good idea. Cutting becomes more exact using a work holder to secure your components since the parts do not move during machining. The part is held stable by a work holder, but you don't have to use a magnetic version.

2.14 Make changes to the process system

There are various techniques to enhance the machining process. Employees should be considered first since they are the ones who will run the devices in an organized or unorganized manner, and if they do not know, they may waste time or make mistakes. If the company decides to upgrade its CAM software, it must ensure that all of its personnel are adequately informed in its use. The computer will generate errors as a result of the faulty data if it is entered into the system. Operations will be improved by upgrading the software and technology to allow higher levels of accuracy. By looking forward up to 1,000 lines of point data in the software, the equipment could now forecast where it wanted the tools to travel.

A change in the travel guiding system is another technique for enhancing CNC machining precision. The X, Y and Z movements determine the travel system's precision. As tolerances for height, width, and parallelism drop, a high-precision trip guiding system with low tolerances becomes more costly. More accurate and precise results are obtained with tighter tolerances. Consider outsourcing the task if your budget doesn't allow for an ultra-precision navigation system for your equipment. The level of support given by the machine bed has an impact on the accuracy of precision machining equipment.

A level, thermally stable, and firm bed absorbs vibrations and supports the machine's moving elements, ensuring CNC accuracy. Equipment accuracy is determined by the interplay between the bed and the foundation. The positioning of the bed's supports at the mounting locations is critical for preventing sagging. Even the most rigid of beds will sink somewhat between places. Ideally, the bed feet should be 60 percent of the length of the bed away from each other. The feet of the bed serve as both ventilation and support points, preventing the bed from sagging. Also Place the third support in the middle of the other two. Machine precision is achieved by decreasing bed sag.

2.15 The Condition of the machine

The completed result will not be as accurate as it might be if the machine is not calibrated correctly or is showing signs of wear and tear. As a result, the machine's status has an impact on the end product's precision and accuracy.

2.16 Watch out for tool deterioration.

The rough contact between the tool and the workpiece causes tool deterioration. It reduces tooltip size and change the geometry of the tool cutting edge. This might lead to the tool cutting incorrectly and producing low-quality pieces.

2.17 Advanced Programming Abilities

The most important aspect of CNC machining is programming. A skilled programmer may use the intrinsic program intelligently, minimizing the CNC system's cumulative error while simultaneously increasing the flexibility of the main program and subroutines.

We usually employ a multi-piece processing method when dealing with complicated molds. We should utilize the relationship between the main program and the subprogram if there are several shapes that are the same. Then, in the main program, repeat the subroutine until the end of the machining. We can then guarantee that the processing dimensions are consistent and increase processing efficiency.

When a piece of data changes, incremental computation seeks to save time by only recalculating those outputs that are dependent on the updated data. Incremental computing frequently results in a specific cumulative error of continuous running of multi-segment programs. Absolute computing is used to develop a software that reduces the CNC system's cumulative error and ensures processing correctness.

2.18 Minimizing the process system's thermal deformation

The machine tool's thermal inaccuracy is affected by cutting speed, feed, machining time, and ambient temperature.

2.19 Using Made-to-Order Parts to Increase Accuracy

Obtaining high levels of precision and accuracy takes a long time and gets expensive. Not many machine shops provide these services because the expense of upgrading to high or ultra-high levels of precision is typically prohibitive. When orders for high-precision parts are received, some firms will outsource the work to shops that can produce the parts with the requisite precision. It’s a business plan that will allows companies to enhance their shop's operations without having to turn away jobs.

Businesses don't have to use made-to-order components for all of their projects. They might be able to complete the majority of the orders they get.Selecting a third-party contractor for a certain project might be beneficial in some ways. For certain applications, using made-to-order parts lowers wear on in-house machinery. Companies save money by not having to replace worn tools or do routine maintenance on their equipment because of not operating them as often.

Furthermore, to process a single order or a limited number of components, you do not need to invest in costly improvements. Consider about how much it would cost an organization to modernize their equipment against the expense of hiring a third-party machine shop. The latter will, in most situations, save money on the project.

With the large commitment of both time and money necessary to make improvements to increase CNC accuracy, selecting a third-party shop can save an organization’s money while providing the benefits of more accurate machining.

Also, a third-party machine shop might invest more money in the equipment they utilize to achieve greater outcomes.

2.20 Improve Cutting Tool

Optimizing cutting tools entails employing a tool that is particularly tailored for the material to be machined. You should choose the cutting tool that is most suitable for your application to attain the desired level of accuracy and precision.

Despite the fact that tool motions in CNC milling are automated, high-quality tools provide value. You should also calibrate your machine tools on a regular basis to ensure that they are operating with the utmost precision.

2.21 Modernize the Machine Tool as quickly as possible

Machine manufacturers nowadays introduce new features and routinely upgrade their firmware to boost efficiency. Users may quickly update them to maximize the value of their investments. Hesitation to modernize the machine tools might lead to a loss of precision and accuracy in parts, perhaps leading to a rise in product recalls.

2.22 Cutting parameters

For each application, the cutting settings must be specified appropriately.

2.23 Keeping measurement inaccuracies to a minimum

Enhance the bearing's rotational precision. High-precision cylindrical roller bearings and multi-oil wedge bearings are among the best options to go for.

3.0 The Advantages of Increasing CNC Machine Positional Accuracy

- Improved Turnaround

The time saved on your projects is one of the key reasons for enhancing the positioning accuracy of CNC machines. Cutting that is more accurate and precise reduces works from needing to be redone. Furthermore, automating several components of machining, such as tool placement, minimizes the amount of time each activity takes. More efficient processes will shorten the time you have to wait for your completed project if you employ the parts generated by machining.

- Data

Variance affect a part's initial accuracy and precision, as well as its capacity to generate precise duplicates. Changing your equipment to eliminate these factors can guarantee that your results are accurate and consistent. Furthermore, you should not be required to measure each completed component. For example, if you want to improve accuracy, you'll need to decrease human input. You may decrease the odds of mistakes by automating the process, allowing for more precise reproduction of each item manufactured. Because the number of errors is limited, you may achieve high accuracy with your equipment by reducing the number of possible errors.

Even if you don't have to measure every item, you should employ laser measurements and ballbar inspection to ensure that your procedures are accurate.

These metrics may help you better estimate when the equipment needs to be serviced or when it needs to be adjusted to increase efficiency.

3.10 CNC Milling Accuracy

The total accuracy of the milled item is determined by three separate measurements: position accuracy, accuracy or repeatability, and tolerance.

a. Accuracy in Positioning

The difference between the required distance between the spots on the component and the actual measured distance of these points after milling is the position accuracy. The ability of a CNC milling machine to follow its planned route determines accuracy. By collecting repeated measurements and determining the statistical average of the variances, the machining shop may assess the rolling mill's accuracy.

b. Repeatable Accuracy

The milling machine's precision and accuracy is determined by carefully repeating the same commands so that each part produces the same outcome. When directing the CNC milling machine's cutting path, the workshop may calculate the precision of the machine by taking repeated measurements. The repeatability of cutting the same precise route again and over again, resulting in an accurate replica of the component, is the measure of precision.

c. Tolerance

When referring to the permissible variation from the CNC milling machine to measure the set value, machinists and engineers use the word tolerance. The milling machine is programmed by CNC programmers and machinists to produce components within the customer's tolerances. The milling machine should keep within the stated measurement value's tolerance when cutting materials and manufacturing products. The purpose of a CNC milling machine is to consistently maintain high positioning accuracy while staying within a given tolerance range.

When machining a batch of components, repeatability without accuracy will yield no usable results since the pieces will be out of tolerance as well. Alternatively, if precision is sacrificed for repetition, just one or two components will be provided. Precision and repeatability will result in full batches of unbroken items. Your items' quality is ensured by the machining shop's accuracy.

3.11 The Effects of CNC Machining Precision and Accuracy on a Wide Range of Industries

i. Energy

Machines and equipment used to create and manage energy, whether it comes from natural gas and oil or other sources, requires precision-machined parts that can endure extreme pressure.

ii. Medical

Precision machined micro- and macro-sized parts are employed in machines and equipment used in medical operations

iii. Aerospace

To guarantee the safe functioning of the aircraft irrespective of the surroundings, aerospace components must adhere to the tightest tolerances.

4.0 Conclusion

The necessity for accuracy and precision in CNC milling is a hot topic these days. Many argue the industry has grown extremely focused on these two elements, whereas others consider they are still two of the most important components of the process. In every industrial process, precision and accuracy are unquestionably important. Several considerations, such as speed, efficiency, and cost, must be addressed. To get the greatest potential results, it's critical to find a balance between all of these aspects.